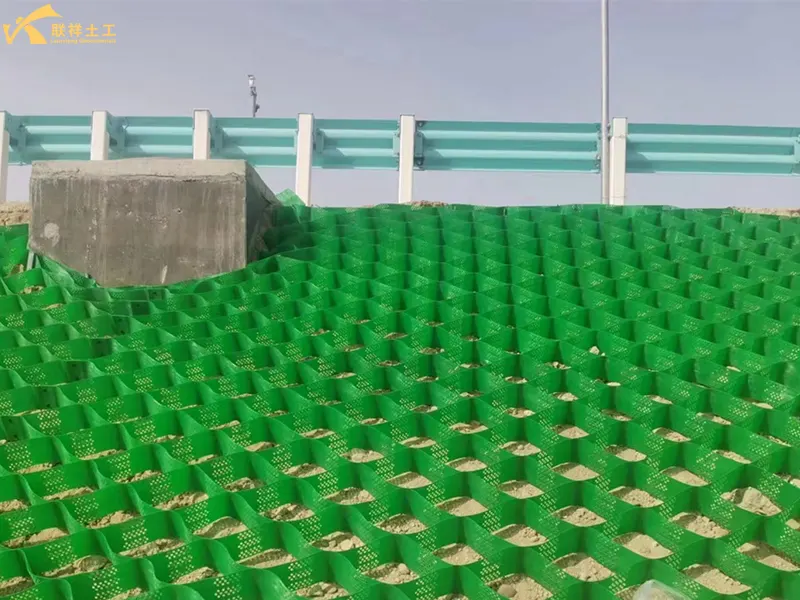

What Methods Can Extend the Service Life of Geocells?

Geocells are used in environments with special construction challenges, thus requiring a high service life. This is mainly because replacement is extremely difficult, and quality problems occurring without natural vegetation can easily lead to greater natural hazards such as landslides and mudslides. Therefore, geocells used in geological disaster mitigation have very strict standards for quality and service life. Today, Lianxiang Geotechnical will explain some common methods to extend the service life of geocells.

1. Precise Material Selection, Matching the Application Environment

The performance of the material itself is the core factor determining its service life. The appropriate geocell type and quality grade must be selected based on the application scenario:

1.1. Selection Based on Material Characteristics

- HDPE (High-Density Polyethylene) Geocells: Strong chemical corrosion resistance and good aging resistance, suitable for general roadbed reinforcement, slope protection, and other conventional scenarios. Virgin HDPE materials should be selected, avoiding recycled materials (recycled materials are prone to embrittlement and have poor aging resistance).

- PP (Polypropylene) Geocells: Highly rigid, but slightly less tough at low temperatures, suitable for warm regions. For cold regions, modified PP material (with added low-temperature resistant agents) should be selected.

- Reinforced Geocells: For harsh chemical environments such as strong acids, strong alkalis, and high salinity, special geocells with added corrosion inhibitors should be selected. For outdoor environments with strong ultraviolet radiation (such as deserts and plateaus), products with sufficient UV (ultraviolet) resistant agents should be selected to ensure that anti-aging indicators meet standards (e.g., carbon black content ≥2%).

1.2. Controlling Material Quality Standards

- Select products that meet national standards (e.g., GB/T 19274-2017 "Geosynthetic Materials - Geocells"), focusing on checking indicators such as tensile strength at break, elongation at break, and anti-aging performance (strength retention rate ≥70% after xenon lamp aging test).

- Avoid purchasing inferior products with insufficient thickness, edge damage, or uneven color, as these products are prone to premature failure under stress or environmental influences.

1.3. Reasonable Structural Design:

- Appropriate Specification Selection: Based on the engineering load, filler type, and foundation conditions, select appropriate cell height, weld spacing, and sheet thickness. For projects with high load-bearing capacity requirements and large filler particle size, taller and thicker cells should be selected.

- Drainage System Consideration: During design, ensure that water does not accumulate inside or at the bottom of the cell layer. Accumulated water will soften the foundation and accelerate material aging. A comprehensive drainage system, including blind drains and permeable pipes, should be designed.

- Protective Layer Installation: Laying a certain thickness of gravel cushion layer on top of the cells before surface layer construction (such as asphalt or concrete) can effectively distribute the load and isolate ultraviolet rays, high temperatures, and mechanical damage.

1.4. Quality Acceptance is Essential

- Product inspection reports, certificates of conformity, and factory lists must be carried with the shipment. During inspection, check the dimensions, color, thickness, and quantity of the products on-site.

- In addition to checking the product's appearance and dimensions, immediately compare the sample with the bulk order. If the difference is significant, the shipment can be rejected.

- At least three products must be randomly selected from the bulk shipment for third-party testing. If one product fails to meet the standards, a second sampling inspection is required. If any product fails to meet the standards in the second inspection, this batch of goods cannot be used in the construction project.

2. Standardized Construction to Reduce Human-Induced Damage

Improper operation during construction can directly damage the geocell structure, reducing its load-bearing capacity and durability. Strict adherence to construction specifications is essential:

2.1. Compliant Foundation Treatment

- Before construction, remove sharp debris (such as gravel, rebar ends, tree roots, etc.) from the foundation to prevent sharp objects from puncturing the geocells. Level and compact the foundation to ensure uniform load-bearing capacity and prevent localized stress concentration that could lead to geocell deformation and cracking.

- If the foundation is soft soil, replacement, drainage, and consolidation treatments must be carried out first to control settlement and prevent damage to the geocells due to excessive stretching.

2.2. Proper Laying and Fixing

- Avoid dragging or pulling the geocells during laying to prevent tearing and deformation. Control the laying slope and overlap width according to design requirements (generally, the overlap width ≥ 10cm). Use special connectors (such as clips and bolts) to fix the overlaps, avoiding the use of easily rusting materials such as wire (rust will contaminate the geocells and reduce connection strength).

- For slope laying scenarios such as slope protection, fixing anchors should be installed at the top, bottom, and middle of the geocells to prevent them from sliding and shifting under rainwater erosion or external forces.

2.3. Backfilling and Compaction Control

- Backfill Material Quality: Backfill materials should be selected from uniformly sized gravel, soil, etc., without sharp edges. Avoid using large-diameter crushed stone to directly impact the geocells. Backfilling should be done in layers, with each layer not exceeding 30cm in thickness. Light or medium-duty compaction equipment should be used to avoid heavy machinery directly compacting the geocells to prevent them from being crushed.

- Paving Method: The principle of "edges first, then center" and "lighter to heavier" should be adopted. First, use light machinery or manual labor to pave from the material transport channel to both sides, and then use heavy equipment for compaction after initial filling. Transport vehicles are strictly prohibited from driving directly on unprotected cells.

- Compaction Process: Compaction should begin at the cell edges and gradually proceed towards the center. Vibratory rollers are recommended, using a "low-frequency, high-amplitude" vibration mode to ensure the filler is fully compacted within the cell grid, while avoiding excessive vibration that could cause weld tearing. The compaction degree must meet design requirements (usually ≥93%) to prevent uneven stress and localized deformation caused by a loose backfill layer.

3. Protect against environmental erosion.

Ultraviolet radiation, chemicals, and biological activity in the natural environment can accelerate the aging and damage of geocells. Targeted protective measures are necessary:

3.1. UV Protection

- For geocells laid outdoors, backfilling and covering should be done promptly to avoid prolonged exposure to sunlight (long-term UV exposure of HDPE and PP materials accelerates molecular chain breakage, leading to embrittlement). If backfilling is not possible in the short term, cover with shade cloth or spray with an anti-UV coating.

- For permanent outdoor applications (such as landscape slope surfaces), composite geocells with a surface-mounted geotextile can be selected. The geotextile effectively blocks direct UV radiation.

3.2. Chemical Corrosion Protection

- In chemical environments such as saline soils and areas polluted by industrial wastewater, in addition to selecting corrosion-resistant materials, an isolation layer (such as geomembrane or non-woven fabric) can be laid between the geocell and the corrosive medium to reduce direct contact between chemicals and the geocell.

- Avoid using geocells in highly oxidizing or acidic environments (such as areas contaminated with sulfuric acid or nitric acid). If this cannot be avoided, a special anti-corrosion coating must be applied.

3.3. Protection against Biological and Physical Damage

- In areas with abundant vegetation, prevent excessive root penetration of the geocells. A root-penetration-resistant geomembrane can be laid beneath the geocells. Regularly clear surrounding weeds to prevent root entanglement and deformation of the geocells.

- Geocells near roads or construction areas must be equipped with guardrails or warning signs to prevent mechanical collisions and human damage.

4. Regular maintenance and timely repair of damage

During long-term use, regular inspections and targeted repairs are necessary to prevent the spread of localized damage.

4.1. Establish a Regular Inspection Mechanism

- Regularly inspect the appearance of the geocells, paying particular attention to joints, fixing points, and areas of concentrated stress (such as roadbed edges and slope midpoints), checking for problems such as tearing, deformation, loosening, and aging/embrittlement.

- Increase the frequency of inspections after rain or extreme weather (such as heavy rain, heavy snow, or high temperatures) to promptly identify potential hazards such as exposed geocells and backfill layer loss caused by rainwater erosion.

4.2. Timely Repair of Damaged Areas

- For small tears, use specialized geomembrane patches (of the same material as the geocells) and geotextile adhesive for repair. The repair area should be 2-3 times larger than the damaged area to ensure a firm bond.

- If a geocell experiences large-area deformation, breakage, or failure of anchor points, it must be partially removed and replaced with a new geocell. The backfill layer should be repaved and compacted to prevent the damage from spreading and affecting the overall structural stability.

4.3. Optimize Surrounding Environmental Conditions

- For roadbed reinforcement scenarios, regularly inspect the roadbed drainage system to prevent water accumulation in the geocells (long-term water accumulation will reduce the bearing capacity of the backfill layer and accelerate geocell aging); promptly clear debris from drainage channels to ensure unobstructed drainage.

- In cold regions, it is necessary to prevent damage to geocells from freeze-thaw cycles. Insulation materials can be added to the backfill layer, or anti-freezing measures can be taken for slopes and other areas in winter.

5. Transportation and Loading/Unloading

- 5.1. Before loading and unloading, the characteristics, weight, packaging, loading/unloading sequence, and destination of the goods must be understood, and a detailed plan must be developed.

- 5.2. Avoid rough handling such as throwing, dropping, rolling, and smashing. Handle with care and ensure smooth operation.

- 5.3. Transportation must be handled by a professional and reliable logistics company. For truck transportation, tarpaulins must be used to avoid sunlight exposure and rain erosion.

6. Other Auxiliary Measures

- 6.1. Strictly adhere to design requirements: The number of geocell layers, spacing, and load-bearing capacity must strictly follow the engineering design to avoid overloading (such as exceeding the design standard for roadbed load-bearing capacity), which could lead to premature damage to the geocells.

- 6.2. Storage: Unused geocells should be stored in a cool, dry, and well-ventilated warehouse, avoiding exposure to direct sunlight, rain, and corrosive substances.

7. Related Questions

7.1 Are geocells considered heavy or light cargo in transportation?

A: Heavy cargo. Geocells are folded up during transportation to save space.

7.2 What is the best season for slope protection engineering?

A: The best time for slope protection engineering is early spring. This is mainly because there is less rainfall in spring, and the plants will sprout after planting.

7.3 Besides geocells, what other geosynthetic materials are needed in slope protection engineering?

A: Mainly drainage pipes, geotextiles for soil and water retention, and ecological bags for foundation stabilization.

7.4 What height of geocells is generally used in river protection engineering?

A: River slopes are mainly used to prevent landslides, and geocells with a height of 50 or 75 mm are usually used.

7.5 What are the commonly used methods for testing the compressive strength of geocells?

A: Use a platen compression testing machine, apply load at a rate of 1 mm/min, and record the compressive load corresponding to the settlement.

8. Conclusion

To maximize the service life of geocells, the following core principles must be followed:

- Right Selection: Select products with excellent materials and appropriate specifications based on the engineering environment (acidity/alkalinity, UV intensity, load, etc.).

- Proper Laying: Ensure the foundation is flat, tension is sufficient, and anchoring is secure.

- Compaction: Use high-quality fill material and employ correct spreading and compaction techniques to ensure the geocells and fill material work together effectively.

- Prevention and Drainage Integration: Ensure proper protection of the upper layer and drainage of the lower layer to isolate sources of damage.

- Frequent Inspection and Maintenance: Establish a system for regular inspection and timely maintenance.

The above are common methods for extending the service life of geocells, analyzed by Lianxiang Geotechnical from multiple aspects including material selection, design, construction, transportation, storage, and post-maintenance. We hope this information will be helpful when using geocells in the future. By employing the above methods, geocells can be protected throughout their entire lifecycle, from initial construction to use, effectively extending their service life and ensuring the long-term stability of the engineering structure. In practical applications, protection strategies need to be tailored to the specific characteristics of the engineering scenario (such as roadbed, slope, foundation treatment, etc.).

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188