- Description

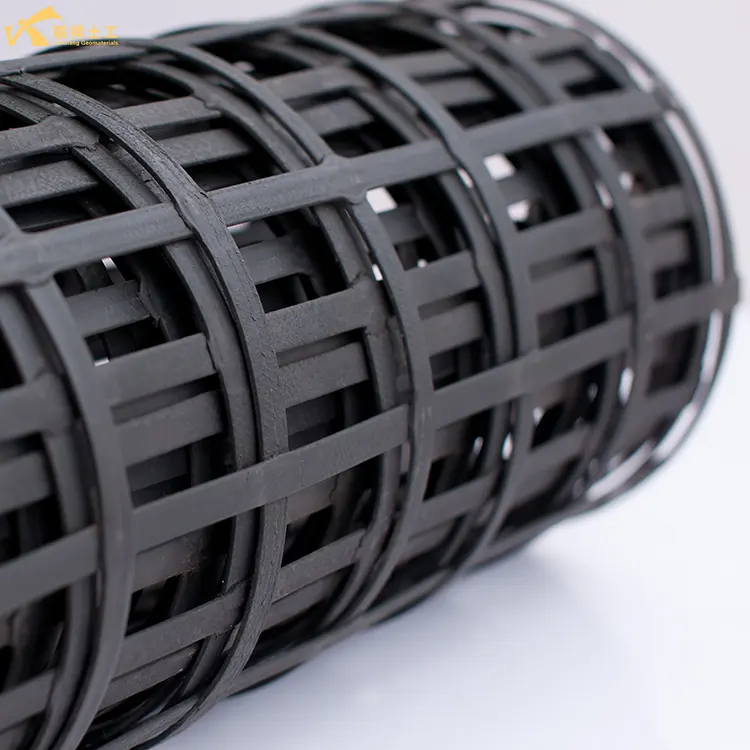

Steel-plastic composite geogrid is a geosynthetic mesh structure made of high-strength steel wire coated with polyethylene (PE) or polypropylene (PP) plastic through a special process. It combines the high strength of steel with the corrosion resistance of plastic, making it an excellent geotechnical reinforced material.

Structure and Manufacturing Process

- 1. Core Material: High-strength steel wire (usually high-carbon steel wire or alloy steel wire, with a phosphate-treated surface).

- 2. Outer Layer Material: Polyethylene (PE) or polypropylene (PP) plastic, which protects the steel wire and prevents rust.

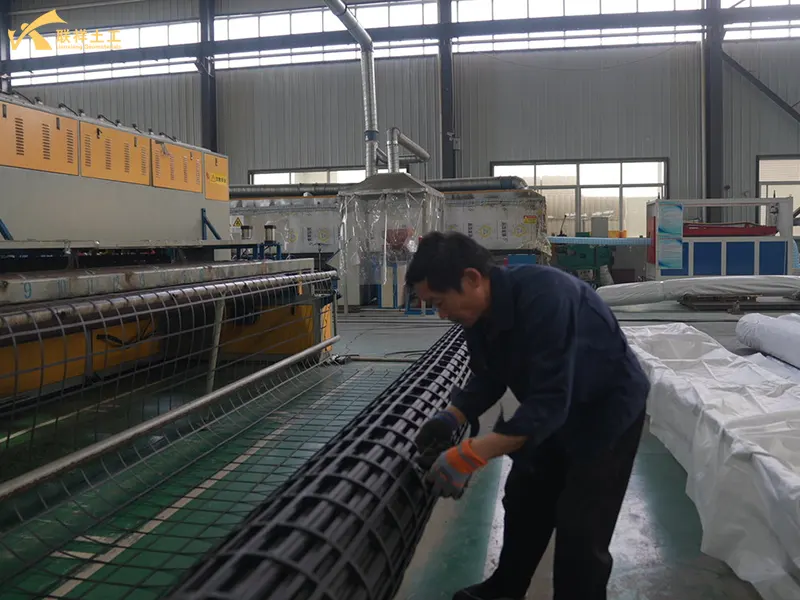

- 3. Manufacturing Process:

- Multiple high-strength steel wires are arranged in parallel at regular intervals.

- Through an extrusion coating process, a protective plastic layer is applied to the steel wires to form a "core rope."

- These core ropes are precisely positioned and welded using ultrasonic and other techniques to form a uniform, intersecting mesh structure.

Main Features and Advantages

- 1. Extremely High Tensile Strength: Due to its core of high-strength steel wire, its tensile strength is far higher than that of pure plastic grating, typically exceeding 100 kN/m or even higher.

- 2. Low Creep: Creep refers to the gradual increase in deformation of a material under a constant load over time. Steel-plastic grating exhibits minimal creep, maintaining stable performance over time and ensuring the long-term safety of the project.

- 3. Excellent Durability and Corrosion Resistance: The plastic coating completely isolates the steel wire from corrosive environments (water, soil, acids, alkalis, and salts), eliminating the problem of steel rust and extending its service life.

- 4. Excellent Soil Interlocking: The regular mesh structure provides a strong interlocking and interlocking effect with the soil, effectively transferring and dissipating stress in the soil to the grating, thereby limiting lateral displacement.

- 5. Convenient Installation: Lightweight and supplied in roll form, it is easy to transport and install on-site. It can be cut and connected to meet project needs.

Main Functions

- 1. Reinforcement: Distributes loads, withstands tensile stresses, enhances the integrity and stability of soil or structural layers, and prevents uneven settlement.

- 2. Reinforcement: Combines with the soil to form a composite structure, significantly improving foundation bearing capacity, slope stability, and the anti-slip and anti-overturning capabilities of retaining walls.

- 3. Stress Diffusion: Distributes concentrated loads more evenly over a larger area, reducing pressure on the underlying soft foundation.

Typical Applications

Steel-plastic composite geogrids are widely used in various civil engineering projects requiring high-strength reinforcement:

- 1. Roadbed reinforcement for highways, railways, and airports: particularly for soft soil foundation treatment to prevent cracking and collapse.

- 2. Reinforcement and protection for embankments, riverbanks, and slopes: Improving slope stability and preventing landslides and soil erosion. Often used in conjunction with three-dimensional vegetation nets, etc.

- 3. Large Retaining Walls: As a key material for reinforced earth retaining walls, they work together with backfill to form a stable, upright structure.

- 4. Large parking lots, port cargo yards, and storage yards: Strengthen the foundation to distribute the massive loads generated by heavy vehicles and stacked containers.

- 5. Landfills and tailings dams: Strengthen the dam body to improve stability.

Key Points for Construction and Paving

- 1. Base Preparation: The paving surface should be flat and compacted, and hard objects such as tree roots and sharp rocks should be removed to prevent puncture of the grating.

- 2. Laying Direction: The primary load direction (usually longitudinal) should be perpendicular to the roadbed axis or parallel to the slope.

- 3. Tensioning and Fixing: During laying, the paving should be straightened and smooth, adhered closely to the base, and wrinkles should be avoided. U-shaped nails or wooden stakes can be used for fixing.

- 4. Overlap and Connection: The longitudinal and transverse overlap widths should generally meet design requirements (e.g., 15-20 cm). Plastic tape or connecting rods can be used for secure fastening.

- 5. Timely backfill: After laying, the fill material should be covered promptly to avoid prolonged exposure to the sun. Rolling should start from the center and work toward the sides. Machinery should not be driven directly over the uncovered grating.

Differences from Other Geogrids (such as Plastic Geogrids)

| Characteristics | Steel-Plastic Composite Geogrid | Plastic Geogrid (such as PP, HDPE) |

| Core Material | High-Strength Steel Wire | Plastic (Polypropylene, High-Density Polyethylene) |

| Strength | Very high, reaching 200-2000 kN/m | Medium, typically less than 100 kN/m |

| Creep | Very low, stable long-term performance | Relatively high, strength may decrease under long-term loads |

| Applicable Environments | Major projects requiring high strength and low deformation | Conventional reinforcement projects with less stringent strength requirements |

| Cost | Relatively high | Relatively low |

Summary

Steel-Plastic Composite Geogrid is a high-quality reinforcement material with high strength, low creep, and corrosion resistance. It perfectly combines the advantages of metal and polymer materials, making it particularly suitable for major engineering projects requiring extremely high strength and long-term stability. It is an indispensable key material in modern civil engineering construction.

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188