- Description

Uniaxial Plastic Geogrid are mesh-like materials made from high-density polyethylene (HDPE) or polypropylene (PP) through extrusion, precision punching, and then highly stretched in only one direction (usually the longitudinal direction). This unidirectional stretching process aligns the polymer molecules in the stretching direction, resulting in extremely high tensile strength and elastic modulus in that direction, while the strength in the other direction is relatively low. Unidirectional geogrids primarily serve as connectors and force transmission devices.

Core Features

- 1. Extremely High Unidirectional Tensile Strength: This is its most notable feature. In the primary load direction (longitudinal), its tensile strength can be extremely high (up to over 200 kN/m), far exceeding that of bidirectional geogrids. However, its transverse strength is lower.

- 2. Low Elongation (High Modulus): When subjected to tension, it exhibits minimal deformation, enabling rapid reinforcement and effectively restraining soil deformation.

- 3. Unique Grid Structure: It presents a continuous rectangular mesh. The thick joints provide high strength and are resistant to damage during construction. The mesh size and filler provide excellent interlocking and interlocking properties.

- 4. Excellent Durability: Resistant to chemical corrosion, aging, microbial attack, and insect infestation, it offers a long service life and is suitable for permanent projects.

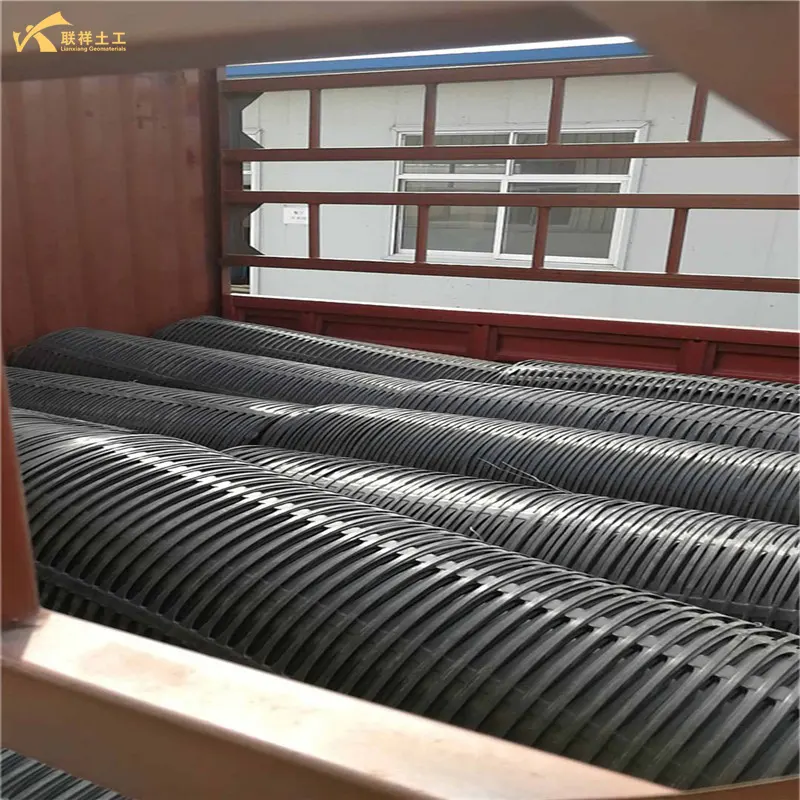

- 5. Convenient Installation: Lightweight and supplied in rolls, it allows for simple and efficient installation.

Working Principle (Reinforcement Mechanism)

The core function of unidirectional grids is to withstand significant tensile forces in a single direction. The mechanism is as follows:

- Passive Impedance: When the soil tends to deform or slip laterally, it embeds itself into the grid's mesh, passively stretching the grid.

- Reinforcement Tension: When stretched, the grid generates significant tensile resistance. Like an anchor, the friction and interlocking forces between its surface and the soil act as a pull-back, preventing further deformation.

- Forming a Stable Composite: The frictional interlocking effect between the grid and the fill transfers and distributes localized unstable loads into a larger, stable area, thereby transforming the loose soil into a stable whole.

A simple analogy: it's like embedding countless high-strength, non-stretching "ribs" in the soil. These "ribs" are anchored within the stable soil layer and serve to hold back any potential slippage.

Main Applications

Uniaxial plastic geogrid are designed specifically to solve engineering problems involving high-intensity, unidirectional loads. Their primary applications are:

- 1. Reinforced earth retaining walls: This is their most classic application. They are used to construct steep, near-vertical slopes and retaining structures, such as road and railway slope protection and bridge abutments.

- 2. Steep Slope Stabilization and Landslide Control: They are used to enhance the stability of natural or artificial slopes and prevent landslides and roadbed collapses.

- 3. Soft foundation treatment: When constructing embankments on soft soil, paving steel on the foundation surface or layered within the embankment leverages its high strength to distribute loads, reduce uneven settlement, and improve overall stability.

- 4. Slope reinforcement for landfills and tailings dams: These projects require extremely high slope stability and anti-seepage measures, and one-way grids are a key reinforcement material.

- 5. Protection and reinforcement of riverbanks and seawalls.

Comparison with Bidirectional Plastic Grating

For a better understanding, we will compare it with bidirectional grating:

| Features | Biaxial Plastic Geogrid | Uniaxial Plastic Geogrid |

| Direction of Load | High strength in both longitudinal and transverse directions | High strength in only one direction (usually the longitudinal direction) |

| Appearance | Grid is approximately square | Grid is rectangular or rectangular |

| Main Function | Distributes loads, provides comprehensive reinforcement, and prevents settlement | Withstands high-strength tensile forces in a single direction and resists slippage |

| Typical Applications | Area-bearing projects such as roadbeds, foundations, and parking lots | Projects requiring high-strength, one-way tensile forces, such as steep slopes, reinforced earth retaining walls, and landslide control |

Key Points for Selection and Construction

- 1. Specification Selection: Selection is primarily based on nominal tensile strength (e.g., TGDG80, indicating a longitudinal strength of 80 kN/m). This must be determined by the design firm based on project requirements and geological conditions.

- 2. Laying Direction: This is crucial! Ensure that the primary strength direction (the direction of highest strength) is perpendicular to the potential slip or load direction. For example, when laying on a slope, the direction of highest strength should be perpendicular to the slope.

- 3. Construction Process:

- Ground Leveling: Clean and level the site, removing sharp objects.

- Laying: Manually tension and level the surface in the designed direction. Lap widths must meet design requirements and securely tie with connecting rods or wire.

- Backfill: Use the backward filling method. Vehicles should not drive directly over exposed geogrids. Start with a light layer of filler and compact the filler with a light touch followed by a heavy touch to avoid direct contact between the roller and the grid.

HDPE Uniaxial Geogrid Specification

| Index Properties | Test Method | Unit | MD Value | |||||

| GG60PE | GG80PE | GG120PE | GG160PE | GG180PE | GG200PE | |||

| Brand | Lianxiang | |||||||

| Polymer | - | - | HDPE | HDPE | HDPE | HDPE | HDPE | HDPE |

| Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 | 2 | 2 |

| Tensile Strength @ 2% Strain | ASTM D 6637 | kN/m | 16 | 23 | 35 | 47 | 52 | 58 |

| Tensile Strength @ 5% Strain | ASTM D 6637 | kN/m | 31 | 44 | 65 | 93 | 104 | 116 |

| Ultimate Tensile Strength | ASTM D 6637 | kN/m | 60 | 80 | 120 | 160 | 180 | 200 |

| Strain @ Ultimate Strength | ASTM D 6637 | % | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 |

| Junction Efficiency | GRI GG2-87 | % | 93 | 93 | 93 | 93 | 90 | 90 |

| Flexural Rigidity | ASTM D 1388 | mg-cm | 1,400,000 | 2,300,000 | 6,000,000 | 19,000,000 | - | - |

| Durability | ||||||||

| UV Resistance | ASTM D 4355 | % | 98 | |||||

| Oxidation Resistance | EN ISO 13438 | % | 100 | |||||

| Brittleness | WashDOT T926 | - | Pass | |||||

| Reduction Factor | ||||||||

| Reduction Factor of Installation Damage (RFid) | ASTM D5818 | - | 1.00 | |||||

| Reduction Factor for Creep of 114-year Design Life (RFcr) | ASTM D5262 | - | 2.23 | |||||

| Dimensions | ||||||||

| Roll Width | - | m | 1 or 2 | |||||

| Roll Length | - | m | 100 | |||||

| Note: MD = Machine Direction | ||||||||

PP Uniaxial Geogrid Specification

| Properties | GG60PP | GG80PP | GG110PP | GG150PP | GG260PP | GG300PP |

| Brand | Lianxiang | |||||

| Tensile Stength (kN/m) | 60.0 | 80.0 | 110.0 | 150.0 | 260.0 | 300.0 |

| Elongation Ratio | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% |

| Strength at 2% Elongation (≥kN/m) | 17.0 | 26.0 | 32 | 45 | 94 | 105 |

| Strength at 5% Elongation (≥kN/m) | 35.0 | 48.0 | 64 | 90 | 185 | 195 |

| Roll Length (m) | 100 | 100 | 50 | 50 | 50 | 50 |

| Roll Width (m) | 1-3 | |||||

Summary:

Uniaxial Plastic Geogrid is a high-performance geosynthetic designed to withstand significant unidirectional tensile forces. It is like a "high-strength steel mesh" in civil engineering, specially used for building steep reinforced soil structures, controlling landslides and strengthening soft foundations. It is an ideal choice for building high-stability and high-steepness civil engineering structures.

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188