- Description

Basic Introduction

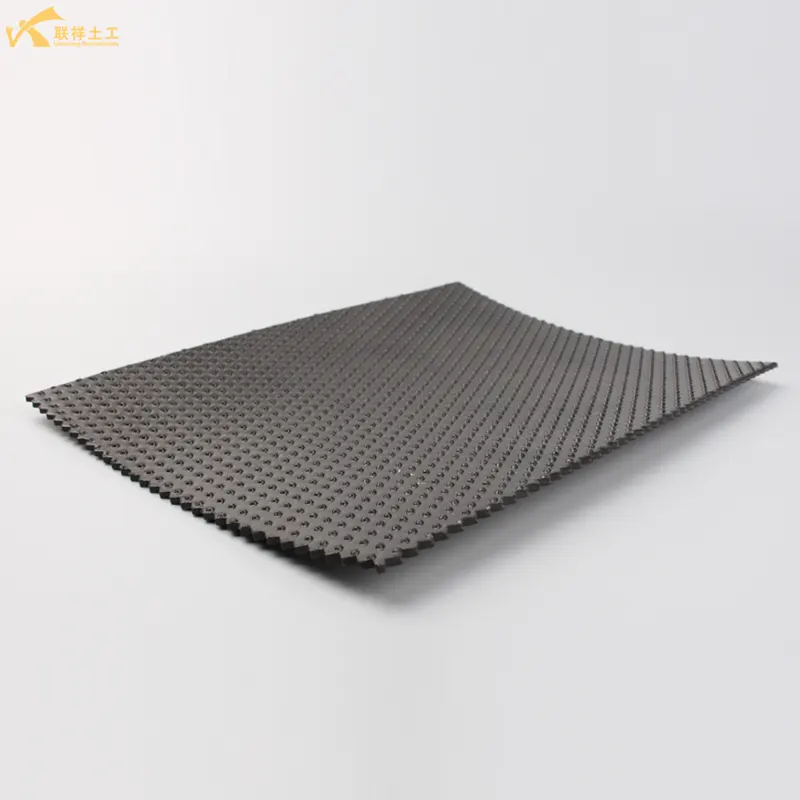

Geomembrane is a thin, extremely low-permeability sheet material made from high-molecular-weight polymers (high-density polyethylene, linear low-density polyethylene). It is classified as a type of geosynthetics, and its primary function is to act as a barrier to prevent the migration of liquids and gases.

Core Characteristics

- 1. Extremely low permeability: This is the core characteristic of geomembranes, effectively blocking various fluids, including water, water vapor, chemical solutions, and methane.

- 2. Chemical resistance: It exhibits excellent corrosion resistance to acids, alkalis, salts, oils, and various organic solvents, making it suitable for a variety of complex environments.

- 3. Aging resistance: By adding additives such as carbon black and antioxidants, it resists UV radiation and oxidation, extending its service life in exposed environments.

- 4. Excellent mechanical properties: It possesses high tensile strength, tear strength, and puncture resistance, enabling it to withstand certain ground deformations and external loads.

- 5. Convenient installation: It is lightweight and can be processed into larger rolls for easy transportation and on-site installation. The sheets can be welded together to form a complete, airtight barrier.

Main Raw Material Types

- HDPE (High-Density Polyethylene): The most commonly used type. It offers excellent chemical resistance, high strength, and UV resistance, making it cost-effective. It's commonly used in landfills, mines, and other areas. Its rigidity requires more care during installation.

- LLDPE (Linear Low-Density Polyethylene): It's softer than HDPE, with better strain resistance and stress crack resistance, making it more adaptable to unevenly settled foundations.

- PVC (Polyvinyl Chloride): It's soft and easy to lay, offering excellent water resistance and ductility. However, its resistance to UV rays and certain organic compounds is somewhat limited.

- Other types: such as TPO (Thermoplastic Elastomer) and PP (Polypropylene), are used in specific applications.

Applications of Geomembranes

Geomembranes are used extensively, encompassing nearly every engineering application requiring anti-seepage, isolation, and containment. Their primary applications include:

1. Environmental Engineering

This is the most important and largest application area for geomembranes.

- Solid waste landfills: Used in landfill bottom lining and top cover systems to prevent harmful leachate from contaminating the soil and water below and to capture landfill gas. This is a hallmark application of HDPE geomembranes.

- Hazardous waste disposal sites: These sites have higher requirements for anti-seepage protection and typically employ a double-lining system to ensure complete containment of toxic and hazardous materials.

- Sewage treatment plants: Used in sewage regulating ponds, sedimentation tanks, anaerobic ponds, and other areas for anti-seepage protection, preventing wastewater leakage.

- Industrial tailings ponds: Tailings slurry generated after mineral processing in mines contains pollutants such as heavy metals. Using geomembrane liners can prevent contamination of the surrounding environment.

2. Water Conservancy Projects

- Artificial Lakes and Landscape Water Bodies: Seepage control measures are implemented on the bottoms and slopes of artificial water features such as parks, residential areas, and golf courses to maintain water levels.

- Reservoirs and Canals: Seepage control measures are used for the construction or renovation of reservoirs and irrigation canals to improve water resource utilization efficiency.

- Levees and Cofferdams: Serves as anti-seepage core walls or inclined walls to reduce seepage through the dam body and ensure project safety.

- Flood Control Projects: Seepage control measures are used for temporary flood control dikes.

3. Municipal and Construction Projects

- Underground Structure Waterproofing: Waterproofing of basements, tunnels, and subway structures, such as basements and side walls, in combination with traditional waterproofing materials.

- Roof Garden Waterproofing: Serves as a subgrade waterproofing barrier for green roofs.

- Drainage Ditches: Prevents canal water from seeping into the ground and affecting surrounding structures.

4. Mining Projects

- Heap Leaching Tanks: In the hydrometallurgical smelting of metals such as gold, silver, and copper, geomembranes are used to line heap leaching tanks to collect precious metal solutions and prevent loss and contamination.

- Solution Sedimentation Tanks: Used for the storage and sedimentation of various solutions in mining, metallurgy, and chemical processes.

5. Agriculture and Aquaculture

- Aquaculture Ponds: Provide slope protection and bottom waterproofing for aquaculture ponds for fish, shrimp, sea cucumbers, and other species, facilitating cleaning and water quality management.

- Irrigation Reservoirs: Reduce water loss during storage in arid regions due to seepage.

6. Transportation Engineering

- Highway and Railway Roadbeds: In soft soil treatment, these tanks are sometimes used as an isolation and anti-seepage layer to prevent mud and mud from forming on the roadbed.

Construction Brief

Geomembrane installation is highly dependent on proper construction:

- 1. Foundation Preparation: The foundation must be leveled and compacted, and sharp objects such as tree roots and sharp rocks must be removed to prevent puncture of the membrane.

- 2. Laying: Unfold the membrane in the designed direction, maintaining a flat surface and avoiding excessive stretching. Allow for some expansion and contraction to accommodate temperature fluctuations and foundation deformation.

- 3. Welding: Use a dedicated hot wedge automatic crawling welding machine or hot air welding gun to weld adjacent membrane sheets into a single piece. This is the most critical step, and weld quality must be tested with air pressure or vacuum.

- 4. Anchoring: Anchor the membrane at the edges of the structure.

- 5. Protection: After laying, promptly cover with a protective layer (such as geotextile or sand) to protect it from direct sunlight and mechanical damage.

Specification

| Thickness | 0.75 | 1.0 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

| Density g/m2 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 | ≥0.94 |

| Tensile yield strength (N/mm) | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| Tensile breaking strength (N/mm) | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

| Bongation at yield(%) | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 |

| Elongation at break(%) | ≥700 | ≥700 | ≥700 | ≥700 | ≥700 | ≥700 | ≥700 |

| Tear resistance(N) | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| Puncture strength(N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 |

| Tensile load stress cracking | ≥300 | ≥300 | ≥300 | ≥300 | ≥300 | ≥300 | ≥300 |

| Carbon black content(%) | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

Conclusion

Geomembrane, as an efficient and reliable anti-seepage material, has become an indispensable key material in modern environmental engineering, water conservancy projects, and civil engineering construction. Its application is directly related to the safety, environmental protection, and economic efficiency of projects, and plays a vital role in protecting water resources, soil environment, and human health. With advances in material technology, its performance and application areas will continue to expand.

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188