The Savior of Soft Soil Foundations: How Steel-Plastic Geogrids Solve Settlement Problems

Steel-plastic geogrids, with their triple advantages of high strength, low deformation, and strong interlocking, have become the preferred solution for modern soft soil foundation treatment. They not only solve the global challenge of settlement control but also achieve the engineering goals of low cost, short construction period, and high efficiency, providing a solid guarantee for the construction of infrastructure such as highways, railways, and municipal buildings.

1. Settlement Dilemma of Soft Soil Foundations

Fatal Characteristics of Soft Soil Foundations:

- High water content (50%-80%)

- High compressibility (large settlement)

- Low shear strength (weak bearing capacity, only 60-80 kPa)

- Poor permeability (long consolidation time)

Settlement Hazards:

- Building tilting, cracking, and even collapse

- Uneven roads, affecting driving safety

- Pipeline rupture, causing leaks

- Significantly shortened project lifespan and soaring maintenance costs

2. Core Principle: Composite Reinforcement and Stress Diffusion

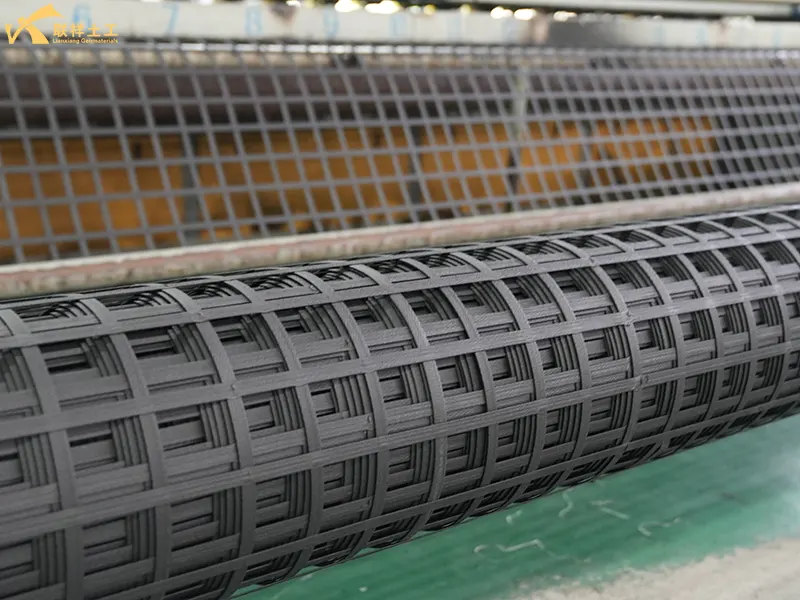

Steel-plastic geogrids are composed of high-strength steel wires and an outer plastic polymer coating, combining the strength of steel with the corrosion resistance of plastic. Its core principle is to significantly improve the mechanical properties of the soil by forming a composite reinforcement with the soil:

- 2.1. High Tensile Strength: The geogrid bears tensile stress, restraining the lateral deformation of the soil.

- 2.2. Mesh Structure: Interlocking with the soil to form an integral structural layer, dispersing the load from the superstructure.

- 2.3. Stress Diffusion: Distributing concentrated loads evenly over a larger area of soft soil, reducing additional stress on the foundation.

3. Four Mechanisms for Solving Settlement Problems

3.1. Lateral Constraint and Overall Stability

- Limiting Shear Deformation: Soft soil is prone to plastic flow under load; the reinforcing effect of the grid creates a "wrap-around effect," limiting lateral extrusion of the soil.

- Improving Shear Strength: Enhancing the shear capacity of the foundation through frictional resistance at the grid-soil interface, preventing local instability.

3.2. Load Distribution and Stress Redistribution

- Reducing Differential Settlement: The grid layer acts as a flexible raft foundation, regulating uneven load distribution and avoiding differential settlement caused by stress concentration.

- Reducing Compression Deformation: Diffusing the pressure from the superstructure to deeper layers, reducing the compression of the soft soil layer.

3.3. Isolation and Filtration Functions

- Preventing Fill Material Subsidence: Isolates fill material from soft soil in the roadbed, preventing stones and other materials from sinking into the soft soil, leading to cavities and settlement.

- Maintaining Unobstructed Drainage: Some grid structures allow pore water to drain out, accelerating consolidation (requires combined drainage measures).

3.4. Long-Term Durability

- Plastic Coating for Corrosion Protection: Steel wire is coated with polyethylene or polypropylene, resisting acid and alkaline soft soil erosion, with a lifespan of up to decades.

- Low Creep: The steel-plastic composite structure exhibits minimal deformation under long-term loads, providing continuous and stable support.

4. Key Application Scenarios

- 4.1. Roadbed Reinforcement: Used for soft soil treatment in highways and railways, reducing post-construction settlement.

- 4.2. Embankments and Slopes: Improves stability and prevents landslides.

- 4.3. Stockyards and Airport Runways: Withstands repeated loads and resists fatigue settlement.

5. Construction Key Points

5.1. Selection Guidelines:

- Fill height ≤ 4m: Select 20-40kN/m specification

- Fill height 4-8m: Select 40-60kN/m specification

- Fill height > 8m: Select 60-80kN/m specification

- Prioritize bidirectional geogrids (for more uniform stress distribution)

5.2. Laying Essentials:

- Clear and level the site, ensuring no sharp objects are present.

- The geogrid should be laid flat and with appropriate tension (avoiding slack or excessive stretching).

- Overlap between adjacent geogrids ≥ 20cm and secure with U-shaped nails.

- When laying in layers, maintain a layer spacing of 0.5-1m, and compact each layer after filling.

6. Comparison Advantages with Traditional Solutions

| Comparison Item | Steel-Plastic Geogrid | Traditional Methods (e.g., Replacement, Pile Foundation) |

| Cost | Lower cost, saving 30%-50% on materials and labor | Higher cost, requiring extensive excavation or concrete |

| Construction speed | Fast, high efficiency with mechanized laying | Slow, complex procedures |

| Environmental impact | Small, reduces earthwork excavation and spoil | Large, damages original stratum structure |

| Long-term effects | Continuous reinforcement, adapts to deformation | May require later maintenance |

7. Design considerations and limitations

- Requires professional design: The strength, number of layers, and laying location of the geogrid need to be calculated based on the thickness of the soft soil and the magnitude of the load.

- Drainage coordination: Heavy soft soil requires the use of plastic drainage boards, vacuum preloading, etc., to accelerate consolidation.

- Extreme conditions: For extremely deep soft soil (e.g., >10m), it may need to be used in combination with pile foundations.

Conclusion:

Steel-plastic geogrids, through the synergistic effects of reinforcement, load equalization, isolation, and corrosion protection, transform the "passive bearing" of soft soil into an "actively reinforced composite," fundamentally inhibiting settlement. Its economic efficiency, ease of construction, and long-term reliability make it a preferred solution for soft soil foundation treatment, combining technical rationality and engineering practicality. However, successful application still requires rigorous geotechnical engineering investigation and design to ensure that the technical solution is precisely matched with geological conditions.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188