A New Option for Slope Protection: How Steel-Plastic Geogrids Protect Mountain Safety

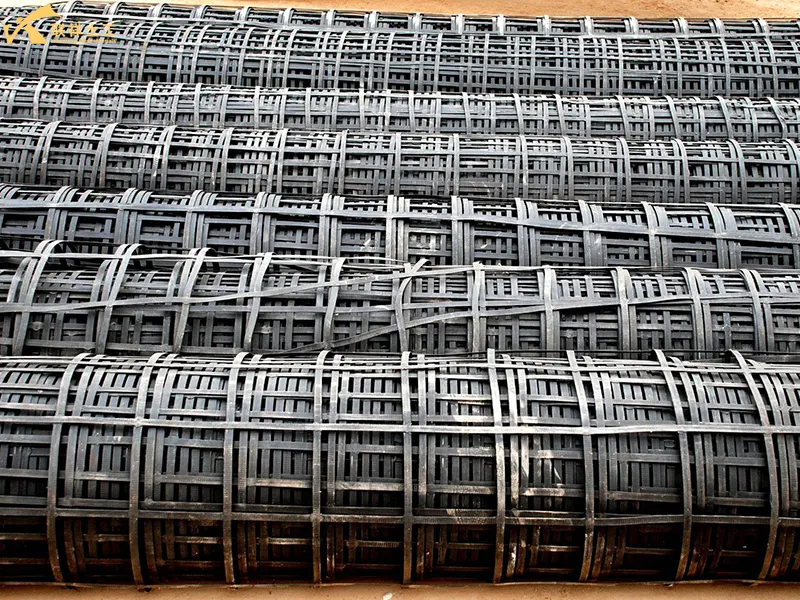

1. What is Steel-Plastic Geogrid?

Steel-plastic geogrid is a high-strength geosynthetic material manufactured using a special process. It combines the strength of steel with the durability of plastic, primarily used for soil reinforcement and engineering structures. In simpler terms, it's similar to "miniature reinforced concrete in the soil." The internal steel wires act like "reinforcing bars," providing strong tensile strength, while the outer plastic layer acts like a "concrete protective layer," preventing corrosion. The entire grid structure "locks" loose soil particles together, forming a strong and stable composite.

2. Core Principles of Slope Protection: Reinforcement and Constraint

The main purpose of slope protection is to prevent landslides. In this process, steel-plastic geogrid plays a role in reinforcing and stabilizing the soil. It doesn't passively retain soil but actively "integrates" into the soil, becoming part of it, fundamentally improving the overall stability of the soil.

2.1. Reinforcing Material Role (Forming a "Skeleton"):

- The geogrid is laid in layers in the soil, its high-strength longitudinal and transverse ribs tightly interlocking with the soil.

- When soil undergoes minor deformation under stress (such as gravity or rainwater infiltration), the grid transfers and disperses the lateral tensile force of the soil through friction and interlocking forces with the soil particles.

- This is equivalent to adding a "steel skeleton" to loose soil, greatly enhancing its tensile and shear strength, transforming potentially slippery soil into a more robust "composite material block."

2.2. Constraint and Isolation Function ("Three-Dimensional Mesh" Wrapping):

- Its unique mesh structure effectively locks in and restricts the lateral displacement and settlement of the filling material.

- It prevents different soil layers (such as fill material and soft soil) from mixing, maintaining the independence and design function of each layer.

3. Reasons for Choosing Steel-Plastic Geogrids for Slope Protection

The choice of steel-plastic geogrids in slope protection projects is undoubtedly due to their inherent advantages. Steel-plastic geogrids perfectly combine the tensile strength of steel wires with the toughness of plastic, giving them both the ability to withstand strong tensile forces and the toughness to withstand localized tension during slope protection. Compared to traditional masonry, concrete, or simple vegetation slope protection, as well as earlier earth-wood geogrids, steel-plastic geogrids offer significant comprehensive advantages.

- High Strength and High Modulus: The high-strength steel wires inside provide core tensile strength, while the plastic coating protects the wires, resulting in extremely high tensile strength (exceeding 100kN/m) and a very low deformation rate, effectively inhibiting soil deformation.

- Excellent Durability: The plastic coating (usually HDPE or PP) completely isolates the steel wires from corrosive environments (acids, alkalis, salts, water, microorganisms), solving the fatal problem of corrosion inherent in traditional steel reinforcement. The design life can reach 50-100 years.

- Good Synergy with Soil: The rough surface and mesh structure provide excellent friction coefficient and interlocking force.

- Flexible Structure: Adapts to certain deformations and settlements of the foundation, less prone to brittle failure like rigid structures.

- Drainage: The grid structure does not impede drainage, facilitating the dissipation of pore water pressure within the slope, crucial for slope stability.

- Locally Sourced Materials: Can utilize local fill soil, reducing the need for transporting high-quality fill materials from elsewhere.

- Quick Construction: Simple installation, no large equipment required, short construction period.

- Low Overall Cost: Material, transportation, and maintenance costs are typically lower than traditional structures like concrete.

- Eco-Friendly: Surface can be covered with soil for greening, combining engineering protection with ecological restoration.

4. Type Selection Guide:

In slope protection engineering, the most critical selection criterion is mechanical performance indicators. Selection must be based on the standards required by the engineering design. Avoid choosing substandard products simply because they are cheap. Lianxiang Geotechnical generally provides a product selection plan based on the client's design requirements, ensuring both project compliance and cost savings.

4.1. Design Mechanical Indicators (Core Basis)

- Long-term Design Tensile Strength (T_d): This is the most critical parameter calculated from the structural design. When selecting a grid, it must be ensured that the long-term allowable tensile strength ≥ T_d.

- Node Strength: Nodes are weak points; their strength must be ≥ the ultimate tensile strength of the grid strips.

- Elongation: Typically required to be ≤3% (under standard tensile force) to ensure structural rigidity and control deformation.

- Creep Performance: The deformation characteristics of the material under long-term load; long-term strength needs to be estimated using the creep reduction factor.

4.2. Filler (Soil) Properties

- Particle Size and Gradation: The maximum particle size of the filler should be less than 1/3 of the grid mesh size to ensure effective interlocking.

- Friction Angle and Cohesion: Directly affects the interfacial friction coefficient (C_i) between the grid and the soil; it needs to be determined through pull-out tests. Rough, angular crushed stone provides the best interlocking effect.

- Acidity/Alkalinity: For special soils (such as those with abnormal pH levels), the chemical corrosion resistance of the plastic coating must be confirmed.

4.3. Environmental Conditions

- Design Service Life: The durability requirements for materials differ between permanent projects (>50 years) and temporary projects (< 5 years).

- Exposure Environment: Whether the material is exposed to harsh environments such as underwater, swamps, or high UV radiation affects its aging rate.

- Temperature Range: Extreme high and low temperatures can affect the performance of the plastic and ease of construction.

5. Key Construction Considerations

In the specific construction process, detailed feasibility reports and plans are required from the initial site survey to the pre-construction preparations. Lianxiang Geotechnical has a dedicated construction team with rich experience. Please feel free to contact us if needed.

5.1. Substrate Treatment

- Before laying, the slope surface must be leveled, and sharp stones and weeds removed to ensure a compacted substrate and prevent the geogrid from being punctured.

5.2. Laying Process

- The geogrid should be laid along the slope toe, with a transverse overlap of no less than 20cm and a longitudinal overlap of no less than 15cm. Overlaps should be secured with straps or special clamps. On steep slopes, additional anchor points are required to prevent geogrid slippage.

5.3. Backfilling and Compaction

- After geogrid installation, backfill soil should be spread and compacted in layers (compaction degree not lower than design requirements) to avoid direct compaction of the geogrid and potential damage.

5.4. Corrosion Protection

- Exposed geogrid ends should be sealed with plastic sleeves or treated with anti-corrosion coating to prevent wire corrosion. For slopes submerged in water for extended periods, hydrolysis-resistant plastic-coated geogrids should be used.

6. Core Parameter Table of Steel-Plastic Geogrid

| Parameter Item | Technical Requirements (Example) | Selection Check Points |

| Ultimate Tensile Strength (kN/m) | Longitudinal/Transverse: ≥ 50/50, 80/80, 100/100, etc. | Does it meet the minimum design requirements and have a safety margin? |

| Strength at 2% Elongation (kN/m) | ≥ XX% of Ultimate Strength (e.g., ≥60%) | Very important! Reflects high modulus performance under low strain, controlling deformation. |

| Nominal Elongation (%) | ≤ 3% (typically) | The lower the value, the better the rigidity and the stronger the deformation control. |

| Node Peel Force (N) or Node Strength | ≥ Ultimate Strength | Core indicator! The node must be stronger than the strip; otherwise, it will fail first. |

| Width (m) | Commonly 2.0m, 2.5m, 3.0m, 4.0m | Affects laying efficiency and overlap quantity. |

| Mesh Size (mm) | Such as 120×120, 150×150 | Must match with filler particle size to ensure effective interlocking. |

| Carbon Black Content (%) | ≥ 2% (for HDPE) | Ensures resistance to UV aging. |

7. Summary: What safety does it protect?

- Anti-slip: Through reinforcement, it fundamentally improves the overall and local stability of the slope, preventing landslides and collapses.

- Erosion Prevention: Combined with greening, it effectively resists wind and rain erosion of the slope, protecting the topsoil.

- Deformation Control: It restrains lateral displacement and uneven settlement of the soil, ensuring the long-term safety of the slope and slope-top structures (such as highways and buildings).

- Promoting Ecology: It provides a stable foundation for vegetation restoration, achieving "green protection," reducing soil erosion, and improving the environment.

In summary, steel-plastic geogrids, as a high-performance geosynthetic material, transform soil from a "loose sand" state into a stable "composite material" through their reinforcement, constraint, and isolation mechanisms. With its advantages of high strength, corrosion resistance, ease of construction, and low cost, it has become the preferred solution for protecting mountain safety and achieving a win-win situation for both engineering and ecology in modern slope engineering.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188