Study on the influence of geocell welding process parameters on structural bearing capacity

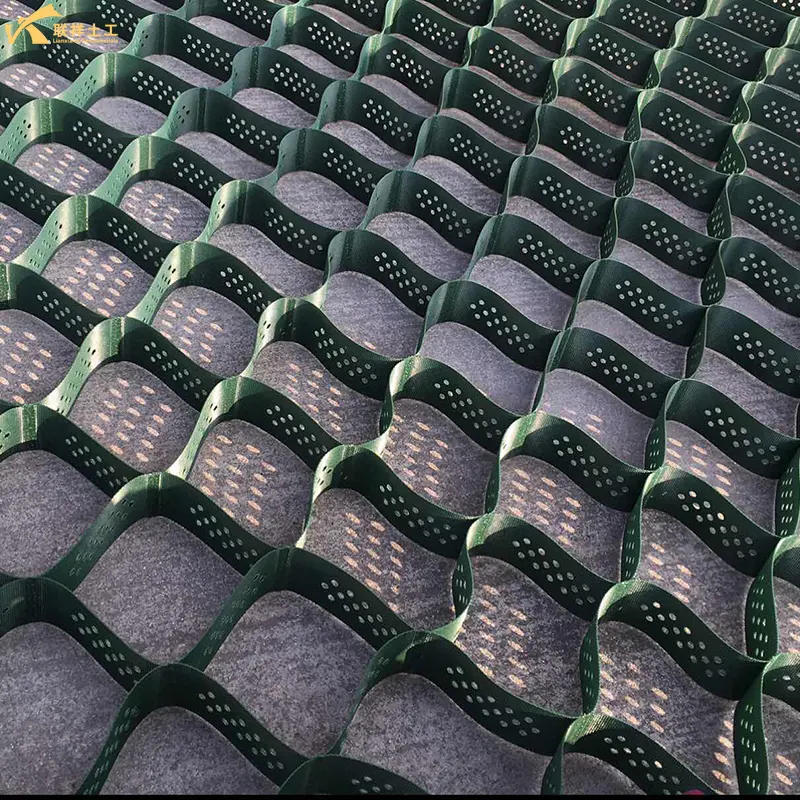

As a three-dimensional mesh-reinforced geosynthetic material, the core performance of geocells lies in the inherent strength of the cell sheets and the connection strength of the welds. In actual engineering, structural failure often occurs not in the sheets themselves, but at the welds. Therefore, welding process parameters directly determine the quality of the welds, which in turn has a decisive impact on the overall structure's load-bearing capacity, deformation resistance, and long-term durability.

1. Core Influencing Mechanism

1.1. Factors Affecting Structural Load-Bearing Capacity

- Weld Strength: Parameters determine the depth and area of fusion of the molten materials. Improper parameters can lead to "cold welds" or "false welds," reducing the effective contact area at the weld and causing tearing under loads far below the material's tensile strength.

- Stress Concentration Effect: The edges of welds are natural stress concentration areas. Excellent welding creates a smooth transition zone, reducing stress concentration. However, improper parameters (such as excessively high temperatures leading to material degradation or excessively high pressures leading to excessive sheet thinning) can exacerbate stress concentrations and become the origin of cracks.

- Material Property Changes: The welding process involves localized heating, melting, and then cooling. Inappropriate parameters (such as excessively high temperatures or rapid cooling) can alter the molecular chain structure of polymers (such as HDPE and PP), causing embrittlement or changes in crystallinity, reducing toughness and long-term creep resistance.

- Long-term durability: Welds are the weakest link in a structure and are particularly sensitive to environmental influences (such as UV rays, chemical corrosion, and repeated loads). Poor welds can significantly accelerate the aging process, leading to a sharp decrease in load-bearing capacity over time.

1.2. Key Welding Process Parameters

Geocell welding is based on the principle of "thermoplastic material fusion." The core process parameters fall into three categories (Table 1), and their interactions require special attention:

| Parameter Type | Specific Indicators | Mechanism of Action |

| Heat Input Parameters | Welding Temperature, Hot Plate Preheating Temperature | Controls the softening/melting degree of the substrate and determines the molecular diffusion capacity |

| Mechanical Parameters | Welding Pressure, Holding Time | Ensures close contact at the weld interface and promotes cross-linking of molecular chains |

| Time Parameters | Heating Time, Cooling Time | Regulates the formation of the fusion zone to avoid defects (e.g., voids and cracks) |

| Geometric Parameters | Weld Spacing (cell size), Weld Width | Affects the structural force distribution and determines the overall deformation resistance |

1.3. Bearing Capacity Evaluation Indicators

An evaluation system should be constructed from two perspectives: "local weld strength" and "overall structural bearing capacity":

- Local indicators: Weld tensile strength (interfacial peel strength), weld shear strength (resistance to shear failure), weld elongation at break (resistance to deformation toughness).

- Global indicators: Compression bearing capacity (core for roadbed scenarios), pullout bearing capacity (core for slope protection), and long-term creep bearing capacity (long-term stability of soft soil foundations).

2. Mechanisms of the Impact of Key Welding Process Parameters on Bearing Capacity

Welding process parameters influence local weld strength by regulating the quality of the fusion zone (at the microscopic level), ultimately determining overall bearing capacity. The following analysis focuses on these key parameters:

2.1. Welding Temperature: A Key Factor Affecting the Molecular Bonding State in the Fusion Zone

Welding temperature is crucial for the "softening-melting-bonding" process of thermoplastic materials. Its impact on bearing capacity exhibits a nonlinear relationship that increases first and then decreases. The specific mechanism is as follows:

Too low a temperature (< 20°C below the base material softening point):

- The base material is only slightly softened, resulting in weak molecular chain mobility. Consequently, an effective fusion zone cannot form at the weld interface, and the connection relies solely on physical adhesion. At this point, the tensile strength of the weld is less than 50% of the designed value, making it prone to "interfacial debonding" under external forces, leading to premature structural instability (e.g., localized subgrade collapse).

- For example, the softening point of HDPE geocells is approximately 120°C. If the welding temperature is below 100°C, the shear strength of the weld is only 0.8 MPa (normal operating conditions require ≥1.5 MPa).

Suitable Temperature (softening point ±10°C):

- The substrate is fully softened but not excessively melted. Molecular chains freely diffuse and intertwine at the interface, forming a defect-free "dense fusion zone" (SEM microscopic observation shows the interface disappears, resulting in a continuous molecular structure). At this point, the weld strength approaches the strength of the substrate itself (tensile strength exceeding 25 MPa), and the overall bearing capacity reaches its peak.

Excessive Temperature (>30°C above the substrate melting point):

- The substrate undergoes "thermal oxidative aging," resulting in molecular chain breakage and degradation (e.g., HDPE exhibits significant chain scission at temperatures above 250°C). Bubbles and carbonization defects appear in the fusion zone, becoming a weak point. At the same time, overmolten material will be squeezed out of the weld, resulting in a reduction in weld thickness (over 30% less than the design value), a sudden drop in local strength, and a high risk of weld fracture failure in the overall structure.

2.2. Welding Pressure: Key to Ensuring Tight Interface Contact

Welding pressure compresses the weld interface, eliminating voids and promoting molecular diffusion. Its influence manifests as a "threshold effect":

Insufficient pressure (< 0.2 MPa):

- Microscopic voids exist at the weld interface (porosity >5%), preventing sufficient contact between molecular chains and forming a "discontinuous structure" in the fusion zone. Under external force, these voids become stress concentration points, leading to brittle fracture in the weld and a 40%-60% decrease in shear strength.

- For example, an experiment showed that increasing the welding pressure from 0.1 MPa to 0.3 MPa increased the tensile strength of the weld from 12 MPa to 24 MPa, a 100% increase.

Appropriate pressure (0.3-0.5 MPa, adjusted according to substrate thickness):

- Interfacial voids are completely squeezed out, the density of the fusion zone reaches over 95% of the substrate density, molecular chains are fully cross-linked, and the weld strength and overall load-bearing capacity are simultaneously optimized.

Excessive pressure (>0.6 MPa):

- Excessive compression causes a significant amount of softened substrate to be squeezed out of the weld, reducing the weld width (by 20% compared to the design value) and thickness (by 30% compared to the design value), and even causing "weld perforation" defects. The weld becomes a structural weak spot, prone to "weld tearing" under tensile loads, and the overall deformation resistance is significantly reduced.

2.3. Welding Time: The Key to Regulating the Fusion Zone Formation Process

Welding time (including heating time and holding time) determines the adequacy of molecular diffusion and cooling and solidification, and its influence exhibits a "saturation effect":

Too short a time (heating time < 5s, holding time < 3s):

- Heating phase: The substrate is not fully softened, molecular diffusion is inadequate, and the fusion zone thickness is insufficient (< 0.5mm).

- During the holding phase: The fusion zone is not fully cooled and solidified, molecular chains easily rebound, forming voids, and the weld strength is only 60%-70% of the optimal value.

Appropriate time (heating time 8-12s, holding time 5-8s):

- Heating phase: The substrate softens evenly, and the fusion zone thickness reaches 1-1.5mm (matching the substrate thickness);

- During the holding phase: The fusion zone cools and solidifies under pressure, forming a stable molecular bond structure, and the weld strength reaches saturation.

Too Long a Time (Heating > 15s, Holding Pressure > 10s):

- Excessive heating time: Causes excessive thermal degradation of the base material and reduced performance in the fusion zone.

- Excessive holding pressure: While not directly causing degradation, it can reduce production efficiency and provide no additional benefit to bearing capacity (strength increase < 5%).

2.4. Weld Spacing (Cell Size): A Geometric Parameter Affecting Overall Force Distribution

The weld spacing determines the side length of the geocell cell (typically 200-500mm). Its impact on bearing capacity is reflected in the "size effect":

Too Small a Spacing (< 200mm):

High cell density results in greater overall structural rigidity and improved resistance to local deformation (e.g., improved anti-subsidence properties for roadbeds). However, this increases material usage (increasing costs) and reduces construction flexibility (difficulty adapting to complex terrain).

Appropriate Spacing (300-400mm):

- Evenly distributes load, limiting lateral displacement of the soil through "lateral restraint" and evenly transferring upper loads to the underlying foundation through "load diffusion," achieving a balance between bearing capacity and economic efficiency.

Excessive Spacing (>500mm):

- Insufficient cell stiffness leads to "bulging" under load, weakening the lateral restraint effect and resulting in a decrease in overall bearing capacity (e.g., a 20%-30% increase in subgrade settlement).

3. Research Methodology

To quantitatively analyze the impact of welding process parameters on bearing capacity, a complete research methodology consisting of "parameter control - specimen preparation - performance testing - mechanism analysis" is required (Figure 1):

3.1. Experimental Design: Orthogonal Experimental Method (Multi-Parameter Interaction Analysis)

Using an orthogonal experiment (e.g., the L9(3⁴) orthogonal table), with "welding temperature (A), welding pressure (B), welding time (C), and welding spacing (D)" as four factors, and three levels for each factor, a small number of experiments covering multiple parameter combinations were conducted to determine:

- The significance ranking of each parameter's impact on bearing capacity (e.g., temperature > time > pressure > spacing).

- The optimal parameter combination (e.g., A2B2C2D2) and parameter interactions (e.g., the synergistic effect of temperature and time).

3.2. Sample Preparation: Standardized Welding and Sampling

- Base Material Selection: HDPE (density 0.94-0.96 g/cm³, tensile strength ≥ 28 MPa) was used uniformly to control for variations in base material properties.

- Welding Equipment: A CNC hot plate welder (accuracy ±2°C, pressure ±0.02 MPa) was used to ensure accurate parameter control.

- Sampling Standards: Sampling was conducted in accordance with "Geosynthetics - Plastic Geocells" (GB/T 19274-2003). Five replicate samples were prepared for each parameter set to minimize random errors.

3.3. Performance Testing: Local and Global Combination

| Test Type | Test Method | Core Indicators | Equipment |

| Local Weld Strength | GB/T 19274-2003 Tensile Test | Weld Tensile Strength, Elongation at Break | Electronic Universal Testing Machine (Accuracy ±0.5%) |

| Global Compression Bearing Capacity | Simulated Roadbed Compression Test (Uniformly Distributed Load) | Compression Modulus, Ultimate Bearing Capacity, Settlement | Large Compression Testing Machine (Maximum Load 500kN) |

| Shear Bearing Capacity | Direct Shear Test (Cell-Soil Interface) | Interface Shear Strength, Friction Angle | Direct Shear Apparatus |

| Microstructural Analysis | Scanning Electron Microscopy (SEM) | Fusion Zone Defects (Voids, Cracks), Molecular Bonding State | Field Emission Scanning Electron Microscopy (Magnification 1000-5000x) |

3.4. Data Analysis: Quantitative Modeling and Verification

- Significance Analysis: Analysis of variance (ANOVA) was used to calculate the F value of each parameter to determine the significance of its effect on bearing capacity (P < 0.05 was considered significant).

- Regression Modeling: A multivariate linear regression model of "welding parameters-bearing capacity" was established (e.g., bearing capacity Y = aA + bB + cC + dD + e, where a, b, c, and d are coefficients) to achieve parameter optimization and prediction.

- Verification Experiment: Specimens were prepared using the optimal parameter combination and their bearing capacity was tested to verify the accuracy of the model (an error < 10% was considered valid).

4. Research Conclusions and Optimization Directions

Research Conclusions:

- An optimal parameter combination exists: For a specific geocell material (such as HDPE or PP), there exists an optimal set of welding temperature, pressure, and time that maximizes welding efficiency (weld strength divided by parent material strength) (typically >90%).

- Temperature is the most sensitive parameter: a small deviation in temperature often has a greater impact on weld strength than equivalent deviations in pressure and time.

- Bearing capacity is closely related to failure mode:

- Ideal state: Failure occurs at the parent material, indicating that the weld point is stronger than the parent material, and the bearing capacity is determined by the parent material.

- Common undesirable state: Failure occurs at the weld point, manifesting as brittle fracture, and the bearing capacity is far below the designed value.

- Long-term performance: Cells welded under optimal parameters exhibit significantly better creep and stress cracking resistance than cells welded under inappropriate parameters.

Optimization Directions:

- Process window determination: Through systematic experimental design (such as response surface methodology), a mathematical model is established between welding parameters and weld strength to accurately identify a robust "process window."

- Online quality monitoring: Develop a system to monitor temperature and pressure in real time during the welding process to ensure the stability of process parameters.

- Non-destructive testing technologies: Research non-destructive testing methods such as ultrasound and thermal imaging to enable rapid and comprehensive quality assessment of geocell welds.

5. Parameter Optimization Strategies in Practical Applications

Different engineering scenarios have different requirements for the bearing capacity of geocells. Therefore, welding process parameters must be optimized based on the application scenario (Table 2):

| Application Scenario | Core Bearing Capacity Requirements | Optimal Welding Parameters | Precautions |

| Soft Soil Subgrade | High Compressive Strength, Low Settlement | Temperature 200-220°C, Pressure 0.4-0.5 MPa, Time 10-12 seconds, Spacing 300 mm | Control welding point density to avoid local stress concentration |

| Slope Protection | High Pullout and Deformation Resistance | Temperature 190-210°C, Pressure 0.3-0.4 MPa, Time 8-10 seconds, Spacing 250-300 mm | Enhance weld tear resistance to accommodate lateral slope forces |

| Embankment Reinforcement | High Shear Resistance, Long-Term Stability | Temperature 200-220°C, Pressure 0.4 MPa, Time 10 seconds, Spacing 350 mm | Consider long-term creep to avoid weld degradation |

| Temporary access road | Low-cost, easy to construct | Temperature 180-200°C, Pressure 0.3 MPa, Time 8 seconds, Spacing 400 mm | Optimize economic efficiency while meeting the load-bearing capacity requirements |

6. Research Status and Outlook

6.1. Deficiencies in Existing Research

- Focuses primarily on the impact of a single parameter on short-term load-bearing capacity, while insufficient research is devoted to multi-parameter interactions and long-term creep performance.

- Ignores the influence of environmental factors (such as temperature and humidity) on the relationship between welding parameters and load-bearing capacity.

- Lacks a quantitative correlation model between microstructure (fusion zone) and macroscopic load-bearing capacity.

6.2 Future Research Directions

- Conduct coupled research on "welding parameters, environmental factors, and long-term bearing capacity" to simulate actual engineering conditions.

- Utilize molecular dynamics (MD) simulations to reveal the influence of welding parameters on molecular bonding at the atomic level.

- Develop intelligent welding equipment to achieve closed-loop control of "real-time parameter adjustment and online bearing capacity monitoring."

7. Frequently Asked Questions

7.1 What is the welding height of geocells?

A: Common welding heights include 50mm, 75mm, 100mm, 150mm, and 200mm. Welding heights can also be customized based on project requirements.

7.2 What is the typical welding distance for geocells?

A: Common welding distance parameters include 330mm, 400mm, 440mm, 445mm, 450mm, 500mm, 600mm, 660mm, 712mm, and 800mm. The selection of the welding distance should be based on the project's performance requirements. A larger welding distance results in a lower tensile strength.

7.3 What are the functions of geocell perforation?

A: It provides drainage channels, eliminates hydrostatic pressure, increases bearing capacity, and accelerates consolidation. It also promotes vegetation growth and enhances the long-term stability of the ecological slope protection.

7.4 Is welding required during on-site geocell construction?

A: It depends on the type of geocell and the project requirements. For commonly used geocells, this is not necessary; cells only need to be secured with wire or cable ties.

7.5 What is the approximate service life of a geocell?

A: The service life of a geocell is closely related to its quality. It is generally around 30 to 50 years for commonly used geocells, but can exceed 50 years for specialized industries with specific requirements.

Conclusion

Research on geocell welding process parameters is a key step in ensuring the safety and economic efficiency of geocell engineering applications. Through the systematic research process of "mechanism analysis-parameter identification-experimental verification-numerical simulation", the influence of each parameter can be clarified and scientific and reasonable welding process regulations can be formulated, so as to maximize the bearing capacity of the geocell reinforced structure, extend its service life, and provide important guarantees for the quality of engineering construction. The bearing capacity of the geocell is determined by the welding quality, and parameters such as welding temperature, pressure, time, and spacing jointly affect the bearing performance by regulating the molecular bonding state and structural force distribution in the fusion zone. The research needs to quantify the parameter effects through orthogonal experiments and multi-scale tests (micro + macro), and optimize the parameter combination in combination with engineering scenarios, ultimately achieving the goal of "controllable welding quality, qualified bearing capacity, and optimal economy". This research not only provides theoretical support for the process optimization of geocells, but also lays the foundation for their safe application in major projects.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188