Specific applications of high-density polyethylene geocells in mine remediation

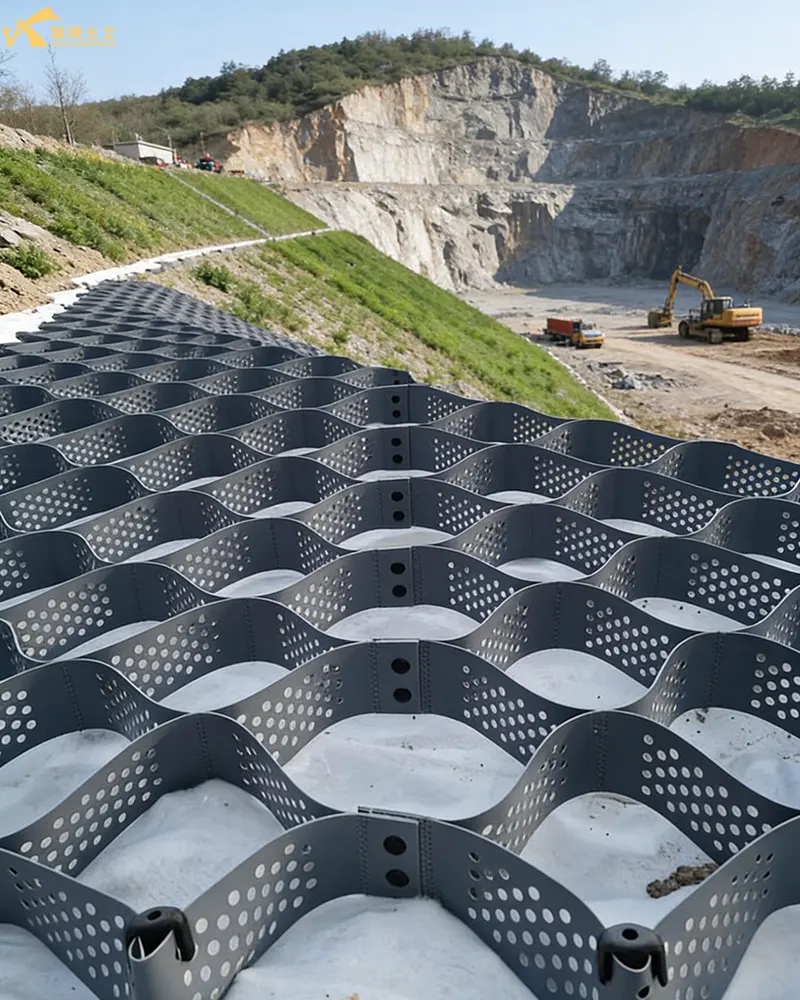

High-density polyethylene (HDPE) geocells are three-dimensional honeycomb structures made of high-density polyethylene (HDPE) sheets welded using ultrasonic welding. They are widely used in core aspects of mine ecological restoration, including slope stabilization, soil and water conservation, and vegetation reconstruction, and are particularly suitable for typical damaged areas in mines such as rock slopes, waste rock piles, and tailings ponds. HDPE geocells achieve integrated "mechanical reinforcement-ecological restoration" in mine restoration, and are especially suitable for steep, barren mine terrain. Through modular construction and flexible structures, they provide an efficient and sustainable solution for mine ecological reconstruction, aligning with the concept of green mine construction.

1. Core Application Scenarios and Technical Solutions

1.1. Ecological Restoration of Mine Slopes (Most Mainstream Application)

Applicable Scope:

- Rock slopes, gravel slopes, and spoil slopes with a slope of ≤1:1 (approximately 45°), especially suitable for difficult-to-repair slopes such as mirror-like rock masses and carbonaceous mudstone.

Typical Combined Processes:

| Combined Scheme | Applicable Conditions | Core Advantages |

| Root Guide Holes + Geocells + Topsoil Spraying + Ecological Anchors | Hard Rock Slopes, Steep Slopes (40-50°) | Improve substrate adhesion, forming a "micro-pillar" slope stabilization system |

| Geocells + Improved Topsoil + 3D Vegetation Net + Spraying | Waste Rock Hills, Spoil Slopes | Constrain loose fill material, constructing a stable growth matrix |

| GCL Waterproof Blanket + Geocells + Topsoil Spraying | Acidic Soil Mining Areas (e.g., Sulfur Mines) | Seepage and acid barrier, creating a suitable environment for plant growth |

| Geocells + Ecological Bags | Extremely steep slopes, localized landslide areas | Double reinforcement, rapid restoration of vegetation cover |

1.2. Comprehensive Management of Coal Waste Hills

- Key Technology: Using 50mm×250mm×250mm geocells, filled with improved soil (with added organic fertilizer, water-retaining agent, and pH adjuster), after stabilizing the slope, a three-dimensional vegetation net is hung, and barren-tolerant grass seeds are sprayed.

- Addresses Pain Points: Problems such as steep slopes, poor stability, barren soil, and weak water retention capacity in coal waste hills.

- Application Case: Restoration of 18 coal waste hills in Fengfeng Group, achieving the dual goals of slope stability and vegetation reconstruction.

1.3. Tailings Dam Slope Protection and Ecological Restoration

- Technical Points: HDPE geocells are laid in layers along the tailings dam slope, filled with a mixture of graded crushed stone and improved soil to form an anti-sliding structural layer, and the surface is sprayed with drought- and salt-tolerant plants.

- Core Functions:

- Prevent tailings loss and control slope slippage caused by hydraulic and gravity forces

- Construct a vegetation growth substrate to restore the ecological environment around the tailings dam

- Reduce dust pollution and lower the safety risks of the tailings dam

1.4. Restoration of Subsidence Areas and Abandoned Mines

- Technical Solution: First, level the site, lay geocells to form a stable foundation, fill with a mixture of soil and tailings sand, and plant suitable vegetation.

- Advantages: Rapidly increases the bearing capacity of the foundation (from 80kPa to over 150kPa), reduces uneven settlement by approximately 40%.

- Applicable to: Surface restoration of coal mine subsidence areas and metal mine goaf areas

2. Standardized Construction Process

2.1. Preliminary Preparation Stage

- Topographic Survey and Scheme Design: Determine the geocell specifications (height 50-200mm), laying layout, and anchoring method.

- Slope Cleaning and Trimming: Remove loose rocks and soil, level the slope, and excavate steps if necessary (4% lateral slope, 15° inward slope).

- Substrate Preparation: Prepare improved topsoil (including soil, organic fertilizer, water-retaining agent, binder, and pH adjuster).

2.2. Cell Installation and Fixing

- Lay from bottom to top, fix at the top of the slope (using U-shaped nails or steel anchors), and lock adjacent cells together to form a unified structure.

- Anchoring System: Arrange anchors in a quincunx pattern, spaced 2m apart, using 14mm steel bars (65cm deep) at the slope toe and 16mm steel bars (80cm deep) for the rest.

- Temporary Fixing: Install temporary support with U-shaped nails to ensure the cells are laid flat.

2.3. Filling Material and Vegetation Establishment

- Filling Material: Fill from bottom to top, to a height of 1.2 times the cell height, tamping firmly to ensure density.

- Vegetation Restoration: Hydroseeding or broadcasting of suitable plant seeds (such as Amorpha fruticosa, Hippophae rhamnoides, Bermuda grass, etc.), covering with non-woven fabric to retain moisture.

- Maintenance and Management: Regular watering, reseeding as needed, ensuring vegetation survival rate.

2.4. Quality Acceptance

- Check the flatness of the geocell installation, the firmness of the connection, and the anchoring depth.

- Test the compaction of the fill material and the stability of the slope.

- Assess the vegetation coverage and growth status.

3. Technical Advantages of HDPE Geocells (Specifically for Mine Remediation)

| Advantage Categories | Specific Performance | Mine Remediation Value |

| Mechanical Properties | High strength, high toughness, anti-aging, resistant to acid and alkali corrosion (suitable for complex mining environments) | Long-term stable slope reinforcement, resisting harsh mining conditions |

| Three-Dimensional Constraint | Honeycomb structure effectively binds the fill material, preventing soil erosion | Controls the slippage of loose materials such as tailings sand and gangue |

| Eco-Friendly | HDPE material is non-toxic and environmentally friendly, providing growth space for plant roots | Promoting root development and forming a stable "root-cell-soil" composite structure |

| Convenient construction | Foldable for transportation, easy to unfold and lay on-site, lightweight and efficient | Suitable for complex mine terrain and areas with inconvenient transportation |

| Economical cost | 30-50% lower cost than traditional concrete grids and shotcrete support | Reduces the total investment in mine restoration projects |

| Durability | Service life of over 50 years, UV resistant and freeze-thaw resistant | Reduces later maintenance costs, suitable for long-term ecological restoration |

4. Application Precautions and Key Technical Parameters

4.1. Cell Size Selection

- Slope gradient ≤30°: Select 100-150mm height cells

- Slope gradient 30-45°: Select 50-100mm height cells

- Special areas (such as landslides): 200mm height cells can be selected, with anchor bolts for enhanced anchoring

4.2. Material Quality Control

- Use only virgin HDPE raw materials; recycled materials are prohibited (as they affect strength and durability).

- Ultrasonic welding strength must meet national standards; weld tensile strength ≥ 1.5 kN/m².

- Cell sheet thickness ≥ 1.0 mm to ensure anti-aging and anti-damage capabilities.

4.3. Special Working Conditions

- High-altitude mining areas: Select HDPE materials with stronger low-temperature resistance and UV resistance.

- Acidic mining areas: Use GCL waterproof blankets or acid-resistant coatings to prevent cell corrosion.

- Areas rich in groundwater: Use well-permeable graded crushed stone as filling material to avoid water accumulation affecting stability.

5. Post-Maintenance Measures

At this stage, the cell structure and ecosystem have formed a stable composite system. Maintenance work mainly focuses on "regular inspections + preventative maintenance," with a focus on preventing extreme weather and mine geological disaster risks.

5.1. Structural Stability Maintenance

- Inspection frequency: Once per quarter, and a comprehensive inspection once a year.

- Inspection Focus:

- Overall Cell Performance: Assess cell durability through professional testing (e.g., sheet tensile strength, weld strength testing). If performance drops below 80% of design standards, a partial or complete replacement plan must be developed.

- Slope Stability: Inspect for cracks and signs of slippage, paying particular attention to the repair slope above the mining goaf. If cracks are found, timely grouting reinforcement and the installation of additional monitoring points are necessary.

- Special Area Maintenance: The toe of the slope and the connection points between the cells and surrounding structures are susceptible to water erosion and external impacts, requiring regular inspection and reinforcement.

- Drainage System Maintenance: Clean the drainage system quarterly and conduct an annual seepage prevention test on the drainage ditches. If leakage is found, repair using geomembrane or cement mortar.

5.2. Ecosystem Maintenance

- Vegetation Maintenance: No artificial watering is required; replant only when large areas of vegetation die. Regularly remove invasive alien species to protect native vegetation communities.

- Ecological Monitoring: Conduct annual monitoring of vegetation cover, species diversity, and soil quality to assess the effectiveness of ecological restoration and provide a basis for subsequent maintenance.

6. Special Measures for Specific Scenarios

6.1. Acidic Mines (Sulfur Mines, Copper Mines, etc.)

- Regularly inspect the acid barrier layer (e.g., GCL waterproof blanket, acid-resistant geomembrane) for damage. If damage is found, repair it promptly to prevent acidic water from corroding the geocells.

- Monitor the pH value of the soil and seepage water quarterly. If acidity increases, add amendments such as quicklime and bentonite to enhance the acid barrier effect.

- Select acid-tolerant vegetation (e.g., ryegrass, tall fescue) and replant regularly to maintain vegetation cover.

6.2. Waste Rock Piles

- Focus on monitoring the risk of spontaneous combustion in waste rock piles. Regularly check the temperature of the geocell filling layer. If the temperature exceeds 50℃, inject water to cool it down promptly to prevent high-temperature damage to the HDPE geocells.

- Dust is easily generated from waste rock piles, requiring regular watering to suppress it, or replanting drought-resistant and barren-tolerant vegetation (such as sea buckthorn and caragana) to reduce dust pollution.

- Check if the cell grids have lost their constraint due to weathering and erosion of waste rock. If the filler layer is loose, add graded crushed stone and compact it.

6.3. Tailings Dam Slope

- Regularly check the cell filler layer for tailings sand loss. If loss is found, promptly fill with tailings sand amendment and add a filter layer (such as geotextile) to prevent fine-particle tailings sand from being lost with water.

- Monitor tailings dam water level changes to avoid excessively high water levels leading to increased hydrostatic pressure on the slope and causing cell structure failure. Before the flood season, reinforce the drainage system to ensure smooth flood discharge.

- Do not pile heavy objects or operate large machinery in the tailings dam slope repair area to prevent cell deformation under pressure.

7. Typical Application Case Results

| Case Name | Application Scenarios | Technical Solutions | Restoration Results |

| Beijing Changping Nankou Quarry | Mirror Rock Slope | Root Guide Holes + Geocells + Topsoil Spraying | Substrate stability improved by 40%, vegetation coverage reached 90% |

| Japan Fukuda Sulfur Mine Area | Acidic Soil Slope | GCL Waterproof Blanket + Geocells + Topsoil Spraying | Successfully solved the problem of difficult vegetation growth in acidic soil |

| Kazakhstan Gangue Mountain | Gangue Mountain Slope | Geocells + Improved Soil + 3D Vegetation Net | Slope stability coefficient increased to 1.35, vegetation coverage reached 85% |

| Mexico High-Speed Carbonaceous Mudstone Slope | Soft Rock Slope | Geocells + U-shaped Nail Fixing + Spraying | Prevents mudstone weathering and erosion, achieving ecological protection |

Conclusion:

HDPE geocells, with their advantages of high strength, three-dimensional constraint, eco-friendliness, and convenient construction, have become a core material for slope stabilization and ecological restoration in mine remediation projects. Through combined application with technologies such as topsoil spraying, ecological anchors, and GCL waterproofing blankets, they can effectively solve the stability and ecological reconstruction challenges in areas such as mine slopes, waste rock piles, and tailings ponds, providing an economical and efficient technical solution for mine ecological restoration.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188