Common classifications of geogrids and their main application areas

With advancements in production technology and the expansion of raw materials, the variety of geogrids is gradually increasing. Each type has its own unique advantages and applications. When purchasing, it's crucial to choose the right geogrid based on your specific needs. Today, we'll introduce the common classifications of geogrids and their primary applications.

Geogrid is a geosynthetic material with a regular mesh structure, made from high-molecular-weight polymers (such as polypropylene, high-density polyethylene, and polyester) through processes such as stretching, weaving, or welding. Its core function is to reinforce, strengthen, and stabilize soil.

I. Common Classifications (By Manufacturing Process and Material)

Geogrids can be primarily categorized based on manufacturing process and raw materials, with manufacturing process being the most common and core method.

1. Classification by Manufacturing Process

This is the most mainstream classification method and directly determines the geogrid's performance and application scenarios.

Plastic Geogrid

Uniaxial Stretch Plastic Geogrid:

- Production Process: Geogrids are made from a polymer sheet that is precision-punched and then subjected to high-temperature, high-pressure stretching only along its length. After stretching, the molecular chains rearrange themselves, significantly increasing their strength.

- Features: High tensile strength in the direction of stretching (the primary strength direction), while strength perpendicular to the direction of stretching is lower. The geogrid has a rib-like appearance, with the node thickness much greater than the ribs.

- Common Materials: High-density polyethylene (HDPE), polypropylene (PP).

Biaxially oriented plastic geogrid:

- Production process: Polymer sheets are punched and then stretched simultaneously in both the length and width directions at high temperature.

- Features: High tensile strength in both directions (warp and weft), forming a square or rectangular grid. This provides more balanced overall performance.

- Common Materials: Primarily polypropylene (PP).

Steel-plastic composite geogrid

- Production process: A core material of high-strength steel wire, glass fiber, or other high-strength materials is covered with a polyethylene or polypropylene plastic protective layer, and then formed by extrusion and stretching. The core material provides extremely high strength, while the plastic layer provides corrosion resistance.

- Features: Extremely high tensile strength (much higher than plastic grids), minimal creep, corrosion resistance, and excellent durability. High rigidity and strong soil adhesion.

Fiberglass Geogrid

- Production Process: Made from alkali-free glass fiber roving, the material is woven and coated with a special coating (usually modified asphalt or polymer).

- Features: Extremely high tensile strength and very low elongation, high temperature resistance, corrosion resistance, and excellent chemical stability. Primarily used for asphalt pavement reinforcement to prevent reflective cracking.

Polyester Warp Knitted Geogrid

- Production Process: Made from high-strength polyester industrial filament, the material is woven through a warp knitting process and then coated.

- Features: High tensile strength, low elongation, excellent acid and alkali resistance, and excellent aging resistance. High friction coefficient with the soil, providing excellent reinforcement. Commonly used in demanding permanent projects.

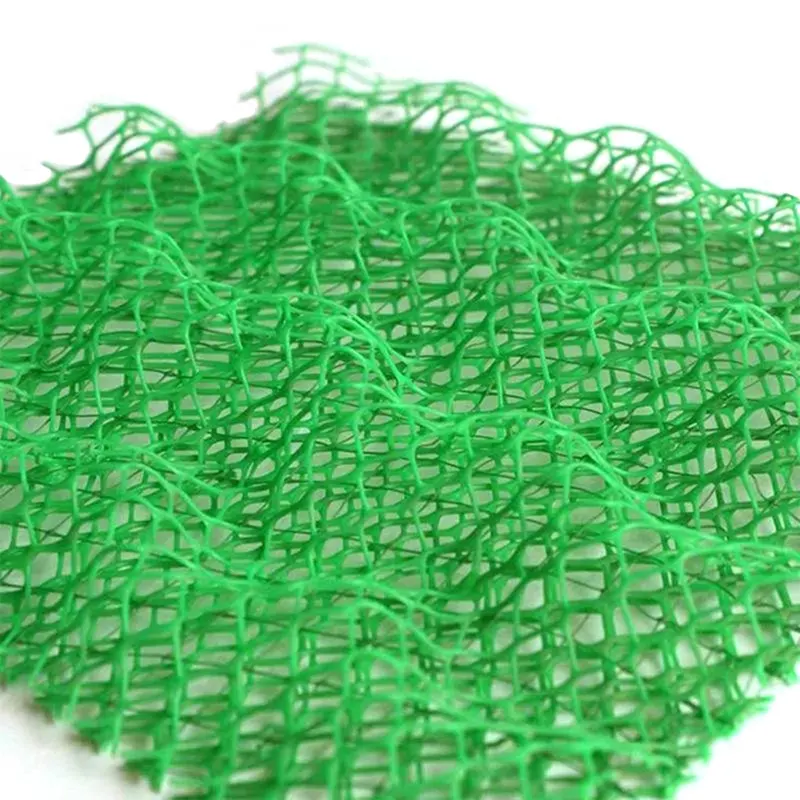

Welded Geogrid

- Production Process: Polypropylene or high-density polyethylene strips are ultrasonically or fusion-welded at their intersections.

- Features: Large openings and moderate strength. Mostly used in areas where strength is not a high requirement, such as drainage and grass planting for slope protection, it provides both reinforcement and protection.

2. Classification by Raw Material

- Polypropylene (PP) grating: Excellent acid and alkali resistance, but poor low-temperature impact resistance. Widely used at room temperature.

- High-density polyethylene (HDPE) grating: Excellent low-temperature and aging resistance, suitable for harsh environments.

- Polyester (PET) grating: Excellent mechanical properties and high modulus, but slightly poor strong alkali resistance.

- Fiberglass grating: Extremely rigid with very low elongation, specifically for road surfaces.

II. Shandong Lianxiang Grid Products

Shandong Lianxiang's geotechnical roadbed reinforcement products include steel-plastic composite geogrids, uniaxial and biaxially oriented plastic geogrids, warp-knitted polyester geogrids, PP plastic welded geogrids, high-strength warp-knitted welded geogrids, and geonets. These products are primarily used in highway and railway roadbed reinforcement, slope protection, retaining walls, and aquaculture.

III. Main Application Areas

Different types of geogrids have different characteristics and focus on different applications.

| Geogrid Type | Core Characteristics | Main Application Areas |

| Uniaxial Tensile Plastic Geogrid | High strength in one direction, low strength in the other | Steep slope reinforcement, embankment reinforcement, retaining walls, landfill slopes, and soft foundation treatment. Primarily used for structures subject to uniaxial tensile stress. |

| Biaxial Tensile Plastic Geogrid | Balanced strength in both directions and excellent stability | Soft foundation treatment, roadbed reinforcement for highways, railways, and airports, parking lots, docks, pipeline foundations, and soil load distribution to prevent uneven settlement. |

| Steel-Plastic Composite Geogrid | Ultra-high strength, low creep, and durability | Large, heavy-load projects: high-speed railways, heavy-duty highways, dams, landslide control, military projects, and applications requiring extremely high reinforcement strength. |

| Fiberglass Geogrid | High strength, low elongation, high temperature resistance | Asphalt pavement reinforcement (new and old roads), preventing and delaying reflective cracking, airport runway reinforcement. |

| Polyester Warp Knitted Geogrid | High strength, high friction, aging resistance | Permanent reinforced soil structures: high retaining walls, bridge abutment bump-off treatment, soft soil foundation reinforcement, ecological slope engineering. |

| Welded Geogrid | Large openings, dual protection | Grassing slope protection (soil stabilization and vegetation growth), drainage system wrapping and protection, soil and water conservation. |

Examples of Applications:

1. Highway/Railway Subgrade Reinforcement:

- Purpose: The geogrid is laid in the subgrade. Through interlocking and friction with the filler, it distributes vehicle loads over a wider area, effectively reducing uneven subgrade settlement and deformation, and extending the service life of the road.

- Common Types: Bidirectional Plastic Geogrid, Steel-Plastic Geogrid.

2. Reinforced Earth Retaining Walls/Steep Slopes:

- Purpose: Grids are embedded in the fill in layers, relying on friction between the grid and the soil to hold the soil in place, forming a stable composite structure. This allows for the construction of nearly vertical, aesthetically pleasing retaining walls or slopes.

- Common Types: One-way plastic grid (main reinforcement perpendicular to the wall), polyester grid, and steel-plastic grid.

3. Soft Soil Foundation Treatment:

- Purpose: Grids are laid on a soft soil foundation, followed by earth and rock fill, creating a "raft foundation" effect. This prevents localized fill collapse and lateral extrusion of foundation soil, thereby increasing the foundation's bearing capacity.

- Common Types: Two-way plastic grid and steel-plastic grid.

4. Pavement Reflective Crack Prevention:

- Purpose: Before adding an asphalt layer to an old concrete pavement or one with numerous cracks, a layer of grid is laid to absorb and distribute stress, preventing cracks in the underlying layer from reflecting onto the new asphalt surface.

- Common Type: Fiberglass geogrid (the best choice due to its compatibility with asphalt).

5. Landfills and Mines:

- Purpose: Used to reinforce landfill dams and slopes, and in conjunction with geomembranes to protect the impermeable layer and improve overall structural stability.

- Common Types: Unidirectional or bidirectional HDPE geogrids (excellent corrosion resistance).

Summary

The choice of geogrid depends on the specific requirements of the project:

- Needing to withstand significant unidirectional tensile forces (e.g., high retaining walls) -> Unidirectional plastic geogrid or steel-plastic geogrid

- Needing to distribute loads and stabilize the foundation (e.g., roads on soft soil) -> Bidirectional plastic geogrid

- Needing extremely high long-term strength and low creep (e.g., heavy railways) -> Steel-plastic composite geogrid

- Mainly used for preventing pavement cracks -> Fiberglass geogrid

- Needing to combine reinforcement and ecological greening -> Welded geogrid

In actual projects, the geogrid selection must be scientifically considered based on design requirements and geological conditions, taking into account parameters such as tensile strength, elongation, mesh size, and durability. The above are the common classifications of geogrids and their main application areas. I hope the above explanation can be of some help to you when purchasing geogrids in the future. Lianxiang Geotech focuses on the production, research and development and sales of various geogrids. If you have any product needs, please call us.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Editor Fan

www.lianxiangcn.com

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188