- Description

Geotextile bag are an emerging, high-tech material for slope protection and greening. They perfectly combine engineering protection with ecological restoration, embodying the concept of "green engineering."

I. What are geotextile bag?

Geotextile bag are double-sided, ironed, needle-punched non-woven bags made primarily from high-molecular-weight polypropylene (PP) or polyester (PET) fibers, crafted through a specialized process. More than just a simple woven bag, they serve as a biodegradable growth medium for plants. Based on local climate conditions, the bag can be filled with soil, sand, preservatives, and other fillers in a scientifically formulated ratio, then seeded with seeds suitable for the local climate. This creates a new product that can restore or create new ecosystems.

Core Structure of geotextile bag:

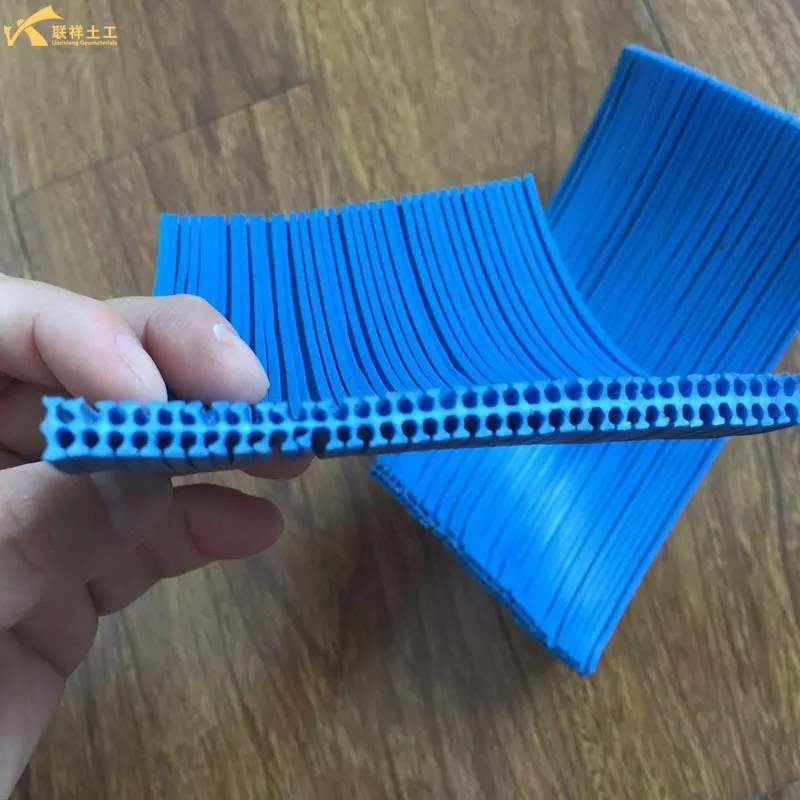

- 1. Bag Material: High-strength, UV-resistant non-woven fabric. This material possesses excellent physical properties:

- Water Permeability: Allows water to pass through, preventing water accumulation and hydrostatic pressure within the slope.

- Soil Impermeability: Prevents soil loss from the bag, maintaining structural stability.

- Anti-aging: UV-resistant ingredients are added to ensure long-term field use (typically designed for a lifespan of 70-120 years).

- Flexibility: Able to adapt to slight deformations in the foundation without breaking.

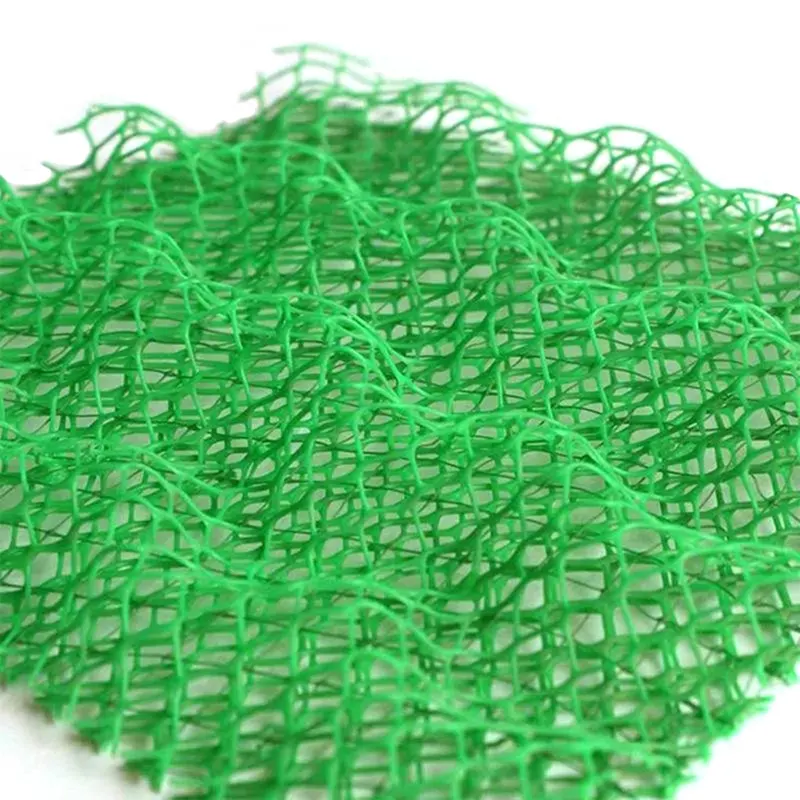

- 2. Functional Layer (Critical): Many high-end Geotextile bag have a seed layer or grass mat attached to the outside. This layer contains a pre-mixed mixture of grass seeds, fertilizer, and water-retaining agents. Once the right conditions (water and suitable temperature) are met, the seeds germinate, and the roots penetrate the bag, tightly connecting the individual Geotextile bag into a single unit, forming a permanent ecological slope.

- 3. Filling: Typically made from locally available materials, a mixture of sand, nutrient soil, and fertilizer provides a foundation for plant growth.

How Geotextile bag Work:

The core of the eco-bag is the synergistic effect of "flexible structure + plant root system."

- Short-term Stability: Initial stability is achieved through the weight of the bag and its filling, as well as the construction methods (such as the use of connecting buckles).

- Long-term stability: After plant germination, roots penetrate the Geotextile bag both horizontally and vertically, like countless "anchor rods," tightly interweaving and entwining the individual Geotextile bag together to form a solid, flexible, integrated slope protection structure. This process is known as "root reinforcement."

II. Outstanding Features and Advantages of Geotextile bag

- 1. Eco-Friendly: They restore natural vegetation, improve the ecological environment, promote biodiversity, and are pollution-free.

- 2. Convenient Construction: The materials are lightweight and easy to transport, and the construction process is simple, requiring no large machinery and resulting in fast construction.

- 3. Durability: They are UV-resistant and corrosion-resistant, with a designed long service life.

- 4. Water-Permeable and Soil-Retaining: They effectively drain water while firmly locking in the soil to prevent soil erosion.

- 5. Strong Self-Healing Ability: Even if partially damaged, the flexible structure and integrated connections prevent overall collapse, and plant roots can regrow and repair the damage.

- 6. Excellent Landscape Effect: They create a naturally green, vegetated slope that blends harmoniously with the surrounding environment.

III. Main Application Areas of Geotextile bag

Geotextile bag have a wide range of applications, covering almost all scenarios requiring slope protection and greening.

1. Slope Engineering:

- Highway and Railway Slopes: They replace traditional mortared stone and concrete slope protection, addressing engineering damage and creating "green corridors" along the road.

- Riverbank and Lakebank Slope Protection: They prevent erosion while restoring shoreline ecology and providing habitats for aquatic life.

- Reservoir and Dam Slopes: They reinforce soil, prevent soil erosion, and beautify the reservoir area.

2. Landscape:

- Rooftop Greening: They serve as lightweight planting media for rooftop gardens and vertical greening.

- Vertical Green Walls: They create ecological walls and unique three-dimensional landscape effects.

- Rooftops and Retaining Walls: They are used to create micro-topography and artistic retaining walls in gardens.

3. Ecological Restoration of Special Difficult Sites:

- Mine Reforestation: They are used to restore vegetation in harsh conditions such as tailings dams and mining incisions, and are a key technology for mine remediation.

- Landfill Cover: Serves as a cover layer, stabilizing the landfill and enhancing greening.

- Saline-alkali Land and Rocky Slopes: By filling with imported soil and a specially formulated seed layer, a plant growth environment is created even in harsh soil conditions.

4. Military and Disaster Prevention:

- Military Shelters: Rapidly construct flexible fortifications.

- Geological Disaster Management: Used for emergency response and ecological restoration at sites of landslides, collapses, and other disasters.

IV. Construction Brief Steps

- 1. Foundation Preparation: Clean and level the slope surface, excavating foundation trenches if necessary.

- 2. Bag Filling: Fill the Geotextile bag to 2/3 or 3/4 of the way with a suitable mixture of soil and fertilizer.

- 3. Stacking: Stack the filled Geotextile bag layer by layer on the slope, with the bag openings facing inward. Use special connectors to connect upper and lower layers, and adjacent bags on the same layer, to enhance overall integrity.

- 4. Watering and Maintenance: After completion, water the bag thoroughly to promote seed germination. Later, necessary maintenance, such as watering and fertilizing, is performed until the slope is fully covered with vegetation.

Summary

As a green, economical, and efficient engineering technology, Geotextile bag perfectly meet the requirements of modern engineering for environmental protection and sustainable development. More than just a product, they are a system solution that integrates engineering structures with ecological restoration, playing an increasingly important role in infrastructure construction, environmental governance, and landscape design.

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188