The important role of geomembrane in the operation of biogas tanks

With technological advancements, the construction of biogas digesters has gradually shifted from traditional cement construction methods to geomembrane construction methods. This is primarily due to the unique advantages geomembrane offer in biogas digester operation. Today, we will explain the important role geomembranes play in biogas digester operation.

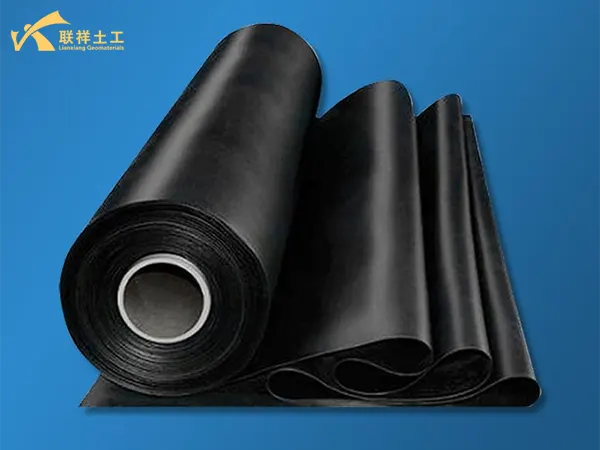

Simply put, geomembranes are a core technology for modern biogas projects, especially fully enclosed anaerobic ponds. They serve as an efficient, reliable, and economical "artificial barrier," solving the most critical issues of sealing, collection, and environmental protection in biogas digesters.

The Important Role of Geomembranes in Seepage Control

1. Core Role: Excellent Seepage Control and Sealing

This is the most fundamental and important role of geomembranes.

- Preventing Groundwater Pollution: The fermentation materials (manure, organic wastewater, etc.) in biogas digesters contain high concentrations of organic matter, nitrogen, phosphorus, pathogens, and other pollutants. Leakage can seriously contaminate the surrounding soil and groundwater. High-density polyethylene (HDPE) geomembranes have an extremely low permeability coefficient (typically less than 10-13 m/s), effectively trapping pollutants within the digester and protecting the ecological environment.

- Preventing Biogas Leakage: Biogas is primarily composed of methane (CH₄), a potent greenhouse gas (with a greenhouse effect over 25 times that of CO₂). The enclosed space created by the geomembrane prevents biogas from leaking into the atmosphere, reducing safety risks while also fulfilling the environmental responsibility of reducing carbon emissions.

- Maintaining the Fermentation Environment: Anaerobic fermentation requires a specific humidity and microbial environment. A good seal prevents the loss of water and nutrients within the tank, creating stable growth and reproduction conditions for methanogens, thereby improving gas production efficiency.

2. Key Function: Efficient Biogas Collection

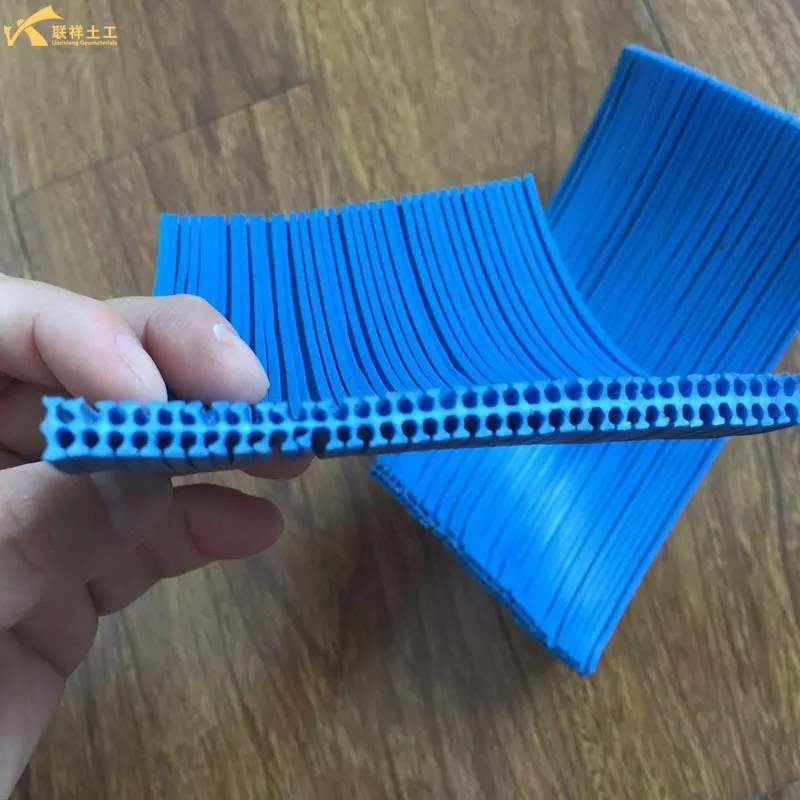

Geomembrane biogas digesters typically utilize a double-membrane structure (double-layer geomembrane) to store and collect biogas.

Working Principle:

- Bottom Membrane: Applied to the bottom and slope of the tank, it primarily provides an anti-seepage seal, isolating the fermentation liquid from the soil.

- Top Membrane: Floats above the fermentation liquid and is typically made of HDPE or a more flexible material. As biogas is produced, the top membrane expands; when the biogas is used, it sinks, forming a variable-volume gas storage tank.

Advantages:

- Integrated Design: Combining a fermentation tank and a gas storage tank, this system eliminates the high cost and complex construction of separate reinforced concrete gas storage tanks.

- Constant Pressure Output: The floating cover of the top membrane maintains a relatively stable pressure within the tank, facilitating the transport and utilization of biogas.

- High Collection Efficiency: Nearly 100% of the generated biogas is collected, avoiding resource waste.

3.Important Function: Improving Fermentation Efficiency

- Heating and Insulation: The black (or black-side-down) geomembrane effectively absorbs solar energy, raising the temperature of the liquid within the tank. Anaerobic digestion efficiency is highly sensitive to temperature (typically peaking at a moderate temperature of 35-38°C). Compared to open oxidation ponds, geomembrane-covered biogas digesters maintain better temperature, significantly increasing gas production and shortening retention time.

- Oxygen Isolation: The tight seal creates an absolutely anaerobic environment, favoring the growth of obligate anaerobic methanogens and inhibiting the activity of aerobic bacteria, making the fermentation process more thorough and efficient.

Important Role in Environmental Protection

1. Curbing Methane Emissions and Addressing Climate Change (Most Significant Environmental Contribution)

- Methane's Greenhouse Effect: Biogas is primarily composed of methane (CH₄). Methane is an extremely potent, short-lived greenhouse gas, with a global warming potential (GWP) 28-36 times that of carbon dioxide (CO₂) over a 100-year timeframe and 84-87 times greater over a 20-year timeframe.

- The Role of Geomembranes: Traditional open oxidation ponds or poorly sealed biogas digesters allow methane to escape into the atmosphere, resulting in a significant carbon footprint. Geomembranes (especially as top membranes) create a completely closed system that efficiently captures over 95% of generated biogas.

- Environmental Benefits: The collected biogas can be used as a renewable energy source, replacing fossil fuels like coal and natural gas for power generation or heating, thereby reducing CO₂ emissions. This means the project achieves "carbon negative" or "carbon reduction" benefits: it avoids direct emissions of the potent greenhouse gas methane and indirectly reduces CO₂ emissions by replacing fossil fuels. This is the most significant positive impact of biogas projects on global climate change.

2. Preventing Groundwater and Soil Pollution (the most fundamental environmental bottom line)

- Pollution Source Characteristics: Fermentation feedstocks such as livestock and poultry manure and organic wastewater contain high concentrations of harmful substances such as chemical oxygen demand (COD), nitrogen (N), phosphorus (P), pathogens, and heavy metals.

- The Role of Geomembrane: High-quality high-density polyethylene (HDPE) geomembranes have an extremely low permeability coefficient ( < 10-12 m/s), acting as a perfect artificial impermeable lining, firmly locking all these pollutants within the biogas tank.

- Environmental Benefits:

- Protecting Groundwater Safety: Effectively prevents the infiltration of toxic and harmful leachate, thereby contaminating valuable drinking water and groundwater resources.

- Protecting Soil Health: Prevents the accumulation of pollutants in the soil, leading to soil salinization, toxicity, and ecosystem damage.

- Laying the Foundation for Subsequent Resource Utilization: Because nutrients are retained, fermented biogas slurry becomes high-quality organic fertilizer and can be safely returned to the fields, forming a circular agricultural model integrating crop production and livestock farming. Leakage would render all of this ineffective.

3. Effectively Controlling Odor and Air Pollution (Improving Regional Environmental Quality)

- Sources of Odor: The anaerobic and aerobic decomposition of organic matter produces highly irritating and malodorous gases such as hydrogen sulfide (H₂S), ammonia (NH₃), and mercaptans.

- The Role of the Geomembrane: The fully enclosed design completely confines these malodorous gases within the system. Collected biogas is typically desulfurized and purified before use to remove malodorous components such as hydrogen sulfide.

- Environmental Benefits:

- Significantly improve air quality at the project site and surrounding areas, protecting the health of workers and nearby residents and reducing complaints and neighborhood disputes.

- Improving the sanitation and public image of facilities such as livestock farms and waste treatment plants makes it easier for them to pass environmental approvals.

4. Promoting waste resource utilization and developing a circular economy (systemic environmental value)

Geomembrane biogas projects are not isolated treatment facilities, but rather a key hub in the circular economy.

- Input: Treat organic waste such as livestock and poultry manure, straw, and food waste as a resource, not a burden.

- Process: Geomembrane biogas digesters safely and efficiently stabilize and harmlessly treat these wastes.

- Output:

- Biogas: A clean energy source used for power generation, heat production, and purification into biogas (BNG) for integration into the pipeline network or as vehicle fuel.

- Biogas slurry and residue: A high-quality organic fertilizer that replaces chemical fertilizers and can be returned to farmland, improving soil structure and reducing agricultural non-point source pollution.

Other Additional Benefits

- Reduced Evaporation: In dry, hot regions, this can significantly reduce evaporation losses within the biogas digester.

- Corrosion Resistance: High-quality HDPE geomembranes offer excellent chemical resistance, resisting corrosion from various organic acids, alkalis, and alcohols produced by the fermentation of organic matter within the digester. This provides a long service life (over 20 years).

Comparison with Traditional Biogas Digester Materials

| Characteristics | Geomembrane Biogas Digester | Reinforced Concrete Biogas Digester |

| Waterproofing | Excellent, seamless throughout | Depends on construction quality, prone to cracks and leaks |

| Construction Period | Short (days to weeks), simple process | Long (several months), complex process, significantly affected by weather |

| Investment Cost | Low (approximately 1/3 to 1/2 of reinforced concrete) | High |

| Flexibility | High, can be designed into various shapes and large capacities | Low, fixed shape, difficult to expand |

| Seismic Resistance | Good, flexible structure can adapt to slight foundation deformation | Poor, rigid structure prone to cracking |

| Maintenance and Repair | Relatively easy, damage can be repaired by welding | Difficult, leak repair technology is complex, and costly |

Summary

Geomembrane is more than just an anti-seepage material in biogas digester construction; it is a revolutionary system solution. By offering comprehensive advantages such as absolute sealing, integrated gas collection, solar heating, and corrosion resistance, geomembrane technology achieves higher environmental standards, lower construction costs, shorter construction periods, more stable operational efficiency, and easier maintenance. These advantages have led to its widespread adoption in large-scale biogas projects and environmental management projects worldwide, making it a key technology driving the modernization of the biogas industry.

This concludes the important role geomembranes play in biogas digester operation. We hope this explanation will be helpful for your future biogas digester construction. If you have any questions, please feel free to contact us.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Editor Fan

www.lianxiangcn.com

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188