Study on mechanical properties and long-term stability of geocell reinforced roadbed

While we're all largely familiar with the primary functions of geocells, the challenges they encounter during their application are less well-known to non-experts. Here, Lianxiang Geotech, a manufacturer, would like to share a key area of current geocell research: the mechanical properties and long-term stability of geocell-reinforced roadbeds.

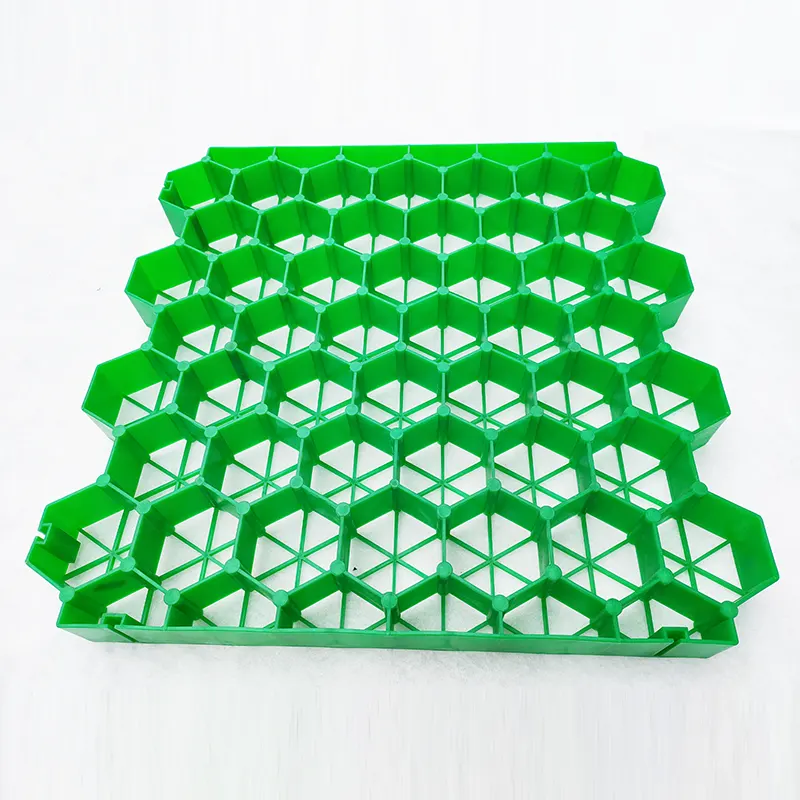

As a new three-dimensional reinforcement material, geocells, with their unique honeycomb structure, can effectively improve the stress state of filler materials and enhance the bearing capacity of roadbeds in roadbed construction. They are widely used in soft soil foundation treatment and fill roadbed reinforcement. In-depth research into their mechanical properties and long-term stability is crucial for optimizing roadbed design and ensuring project durability.

I. Core Mechanisms of the Mechanical Performance of Geocell-Reinforced Roadbed

The mechanical strengthening effect of geocells on roadbeds is essentially achieved through three key mechanisms: structural constraint, stress transfer, and deformation coordination. These can be analyzed from the following four key performance dimensions:

1. Increased Bearing Capacity: The Dual Effect of "Diffusion + Constraint"

The honeycomb structure of geocells distributes upper loads (such as vehicle loads and deadweight) over a wider area of the roadbed filler, reducing localized stress concentrations. Simultaneously, their lateral restraint limits lateral displacement of the filler, forcing it to fully utilize its shear strength.

- Load Diffusion: Through shear transfer through the cell sidewalls, the load diffusion angle is increased from 20°-30° for conventional roadbed to 40°-50°, reducing the additional stress in the underlying layer (such as soft soil) by 30%-50% (based on laboratory model test data).

- Lateral Constraint: The friction between the cell and the filler, as well as the cell's own stiffness, limits the lateral displacement of the filler to 1/3-1/2 of that of conventional roadbed, preventing instability caused by lateral extrusion of the roadbed.

2. Optimizing Shear Resistance: Interface Interactions and Filler Modification

Shear failure is a common form of roadbed instability. Geocells significantly enhance the overall shear strength of roadbeds by improving the interactions between filler particles:

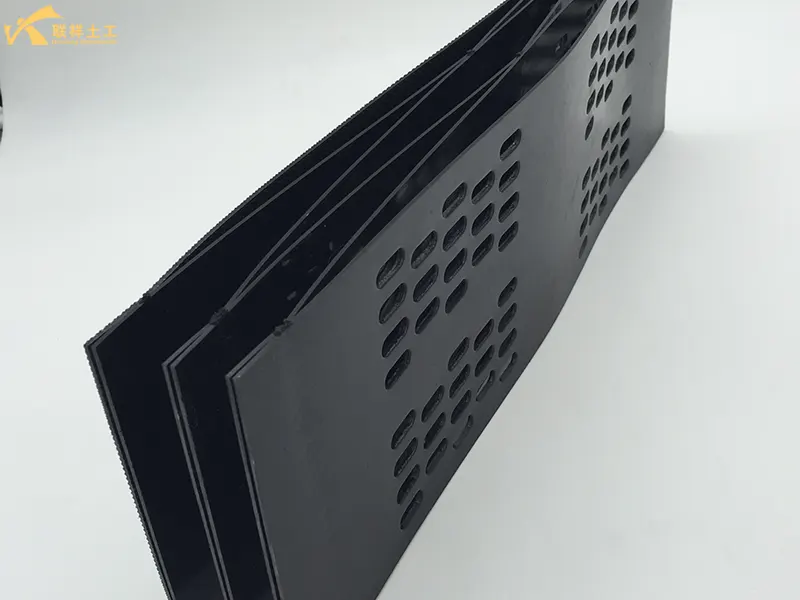

- Interfacial Bonding: The surface texture of the cell material (mostly HDPE and PP) mechanically bonds with the filler particles, increasing the interfacial friction coefficient by 20%-40% compared to conventional roadbeds.

- Filler Consolidation: The cell elements divide the filler into independent "small soil columns," limiting the sliding and rolling of the particles. This increases the filler's internal friction angle by 5°-10° (measured by direct shear tests) and improves cohesion (particularly for sand-based fillers).

3. Deformation Control: Reducing Settlement and Differential Settlement

Geocells control roadbed deformation through two approaches: "immediate deformation suppression" and "long-term deformation retardation":

- Immediate compression deformation: During the filling process, the cells prevent localized depressions caused by uneven fill compaction, improving the roadbed's compaction compliance by 15%-20% and reducing immediate compression by 25%-35%.

- Post-construction settlement: For roadbeds on soft soils, the cells can reduce post-construction settlement by 40%-60% by sharing the load and accelerating consolidation (as demonstrated in applications in deep soft soil areas).

4. Stress Reconstruction: Reducing Local Peak Stress

Under load, conventional roadbeds concentrate stress at the center of the top surface and in localized areas of the base, which can easily damage the underlying layers. Geocells utilize a three-dimensional structure to evenly distribute stress from point to surface, from top to bottom:

- Roadbed Top: Stress distribution is expanded, reducing peak stress by 20%-30%;

- Roadbed Base: Stress uniformity is improved, preventing plastic deformation in soft soil due to local stress exceeding the bearing capacity.

II. Key Factors Affecting the Long-Term Stability of Geocell-Reinforced Roadbeds

Long-term stability is a core requirement for roadbed engineering and is influenced by a combination of factors, including material properties, filler quality, construction techniques, and environmental conditions. Specifically, the following factors are discussed:

1. Geocell Performance Degradation

The long-term performance of geocell materials directly determines the durability of the reinforcement. Key degradation factors include:

- Aging Degradation: Under the influence of ultraviolet light, temperature fluctuations, and humidity fluctuations, HDPE/PP materials undergo oxidative degradation, resulting in a decrease in tensile strength and stiffness (outdoor exposure tests show that strength degrades by approximately 10%-20% after 5 years and by approximately 20%-30% after 10 years).

- Creep Properties: Geocells undergo creep deformation under long-term constant loads. Excessive creep can cause the cell structure to relax and lose its lateral restraint capacity (the creep limit stress of high-quality geocell materials must meet the requirement of "creep ≤ 5% at design load for 100 years").

- Mechanical damage: If cells are punctured by sharp particles or excessively stretched during construction (e.g., during filler paving and compaction), this can cause local structural damage and compromise the overall reinforcement effect.

2. Engineering Properties of Roadbed Filler

The filler is the "skeleton" of the roadbed, and its properties, in synergy with the cell structure, directly impact its long-term stability:

- Filler Particle Grading: Well-graded fillers (such as graded sand and gravel, or soil-rock mixes) have a stronger meshing effect with the cell structure, resulting in less long-term deformation. Overly fine fillers (such as silt and clay) are prone to collapsing due to poor water stability, or cell structure instability due to particle loss.

- Filler Compaction: Insufficient compaction can lead to long-term consolidation and deformation of the filler, increasing roadbed settlement. Ensure that the filler has a compaction of 93%-96% (depending on the roadbed grade requirements) and is tightly bonded to the cell structure to avoid "empty compartments."

- Filler Permeability: Fillers with poor permeability are prone to water accumulation, leading to increased water content and reduced shear strength in the roadbed, which can lead to roadbed softening and landslides. (Water retention within the cell structure should be prevented by providing a drainage layer or selecting permeable fillers.)

3. Construction Quality Control

The standardization of construction techniques is a key factor in ensuring long-term stability. Common issues include:

- Cell laying flatness: Uneven cell laying can lead to localized stress concentration, which can easily cause cell wrinkling and damage during compaction. The flatness error of the laid surface must be ≤5cm/10m.

- Cell connection reliability: Insecure connections between cell units (such as clips and welds) can separate under load, causing the reinforced structure to disintegrate. The connection strength must reach at least 80% of the cell's inherent strength.

- Compacting method rationality: Excessively heavy compacting machinery, excessive speed, or improper compacting sequence can cause cell deformation and damage. A compacting method of "light first, heavy later, edges later, center" should be adopted, with a compacting speed of 2-4km/h.

4. Long-term Effects of Environmental Loads

Long-term erosion from environmental factors is a significant external factor contributing to the deterioration of roadbed stability:

- Water: Rainwater infiltration increases the moisture content of the filler and reduces shear strength (for every 10% increase in the moisture content of clay filler, the shear strength decreases by approximately 30%-40%). Rising groundwater levels soften the roadbed base, exacerbating post-construction settlement.

- Temperature Changes: Seasonal freeze-thaw cycles can cause the filler to frost heave and thaw settle. If gaps exist between the cells and the filler, the frost heave force can destroy the cell structure, and thaw settlement can lead to uneven roadbed settlement (in cold regions, insulation measures are required to mitigate the effects of freeze-thaw cycles).

- Traffic Load Cycles: The long-term, repetitive effects of vehicle loads (e.g., on highways with an average daily traffic volume of over 10,000 vehicles) can lead to creep accumulation in the geocells and fatigue damage to the filler particles. If the load exceeds the design value, this can accelerate roadbed failure.

III. Long-Term Stability Evaluation Methods and Optimization Measures

1. Long-Term Stability Evaluation Methods

The long-term performance of geocell-reinforced roadbeds must be comprehensively evaluated through a combination of laboratory testing, numerical simulation, and field monitoring:

- Indoor Accelerated Aging Tests: Using simulated environments such as UV irradiation, high- and low-temperature cycling, and wet-heat aging, the tensile strength and creep properties of geocells after different aging times are tested to predict their long-term performance degradation patterns.

- Long-Term Creep Tests: Using a graded loading method, the long-term creep curves of the geocell-fill composite under the design load are measured to determine the deformation rate during the creep stabilization phase and determine whether the design requirements are met.

- Numerical Simulation Analysis: Using software such as FLAC3D and ABAQUS, a three-dimensional numerical model of the geocell-reinforced roadbed is constructed to simulate the deformation and stress evolution patterns under the coupled effects of long-term loads (traffic loads, deadweight) and environmental factors (water, temperature) to predict stability during service.

- Long-term on-site monitoring: Settle settlement observation points, stress sensors, and displacement gauges at the construction site to monitor post-construction settlement, lateral displacement, and base stress changes of the roadbed in real time (the monitoring period must be ≥ 3 years, with a focus on the deformation rate in the first year).

2. Optimization Measures to Improve Long-Term Stability

To address the above-mentioned influencing factors, optimization solutions can be proposed from four aspects: material selection, design optimization, construction control, and operation and maintenance:

2.1 Material Selection Optimization:

- Select geocells with excellent aging resistance (such as HDPE with UV absorbers and antioxidants), with a 10-year strength retention rate of ≥ 70%;

- Prioritize well-graded and water-stable fillers (such as graded crushed stone or gravel), avoiding highly plastic clay and silt. If fine-grained soil is required, it should be modified with lime and cement to enhance shear strength and water stability.

2.2 Design parameter optimization:

- Determine an appropriate cell height (typically 10-20 cm) and cell spacing (typically 50-100 cm). Excessive height can lead to insufficient cell stiffness, while too small a height can result in poor load diffusion.

- Optimize the roadbed structure: Install transition layers (e.g., a 10-15 cm thick layer of graded gravel) above and below the cell reinforcement layer to prevent filler particles from penetrating the cells and improve stress transfer.

- Add a drainage system: Install blind ditches on both sides of the roadbed and a permeable layer (e.g., a geotextile + gravel drainage layer) at the bottom of the cell layer to promptly drain water from the roadbed.

2.3 Construction process optimization:

- Before laying the cells, the underlying support layer (such as the cushion layer after soft soil foundation treatment) must be compacted to ensure that the flatness and compaction meet the standards.

- The cells are connected using a dual "double clip + welding" method to ensure connection strength. After laying, the filler is promptly backfilled to prevent prolonged exposure and aging of the cells.

- The filler is spread and compacted in layers, with each layer thickness controlled to 1-1.5 times the cell height. Avoid rolling directly onto the cell edges during compaction.

2.4 Enhanced Operation and Maintenance:

- Regularly inspect the roadbed surface for cracks and settlement, and promptly repair them;

- Maintain the roadbed drainage system to ensure rainwater does not seep into the roadbed;

- For roadbeds in cold regions, winter measures such as snow removal and the installation of insulation can be implemented to reduce the impact of freeze-thaw cycles;

- For sections with heavy traffic loads, regularly monitor roadbed deformation. If abnormalities are detected (such as a sudden increase in settlement rate), timely reinforcement measures (such as grouting reinforcement or the addition of a reinforcement layer) are implemented.

IV. Engineering Application Cases and Research Prospects

1. Typical Engineering Application Cases

- Soft Soil Subgrade Reinforcement: In the deep soft soil areas of southeastern China (such as Zhejiang and Jiangsu), a highway used a "geocell + crushed stone cushion" system to treat its soft soil subgrade. The subgrade width was 26m, the cell height was 15cm, and the filler was graded crushed stone. Monitoring data showed that settlement was only 8 cm one year after construction (compared to approximately 20 cm for conventional roadbeds), and five-year settlement remained stable within 10 cm, meeting design requirements.

- Fill roadbed slope stability: On a highway fill roadbed in a mountainous area in western China (with a slope ratio of 1:1.5), geocells were used to reinforce the slope. The cells were 20 cm high and filled with a soil-rock mix. Long-term monitoring showed that the slope's lateral displacement was ≤ 3 cm, with no cracks, landslides, or other instability observed, demonstrating significantly better stability than unreinforced slopes.

2. Future Research Directions

- Multi-factor Coupling Mechanism: Current research on the long-term performance of geocells under the multi-factor coupling of aging, creep, water, and load is insufficient, and a more accurate coupled damage model is needed.

- Research and Development of New Geocell Materials: Developing new materials (such as modified HDPE and composite materials) that are resistant to aging, creep, and high strength, or incorporating nanoparticles and fibers into geocells to improve long-term performance.

- Intelligent Monitoring and Early Warning: Integrating the Internet of Things (IoT) and fiber optic sensing technology to establish a real-time monitoring and intelligent early warning system for long-term roadbed stability, enabling "early detection and early treatment."

- Green and Low-Carbon Design: Exploring the synergistic application of geocells and recycled fillers (such as construction waste and slag) to reduce carbon emissions and promote the green development of roadbed projects.

V. Conclusion

Geocells can significantly improve the bearing capacity and shear resistance of roadbeds and reduce deformation through the "constraint-diffusion-coordination" effect of their three-dimensional structure. However, their long-term stability is affected by the coupling of material attenuation, filler properties, construction quality, and environmental loads. In engineering practice, the durability of reinforcement must be ensured through "optimal materials, optimized design, standardized construction, and enhanced monitoring." Future research will require further in-depth study of multi-factor coupling mechanisms, promoting material innovation and the application of intelligent technologies to support the sustainable development of geocell-reinforced roadbeds.

In summary, as a manufacturer, we still have a long way to go in the production and application of geocells. We must not only improve the quality of our products but also conduct further research and development in future product areas. Lianxiang Geotechnical welcomes opportunities for professionals in this field to join us for research and discussion.

As a geocell manufacturer, we have an unshirkable responsibility to protect the environment and reduce natural disasters. With the continuous advancement of technology, we believe our home planet will become a better place.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Editor Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188