Basic factors affecting the price per square foot of fiberglass geogrid

Fiberglass geogrids are a familiar material, playing a crucial role in roadbed construction, riverbank protection, and mountain slope conservation projects, resulting in significant market demand. However, many buyers are confused by the wide variety of products available and the inconsistent prices. Therefore, today, Lianxiang Geotechnical will explain the main factors influencing the price of fiberglass geogrids. The price of fiberglass geogrids is determined by three core factors: raw material costs, specifications, and production processes. These factors, combined with purchase volume, brand, logistics, and market supply and demand, form the final price. The following is a detailed analysis of each factor:

1. Basic Concepts

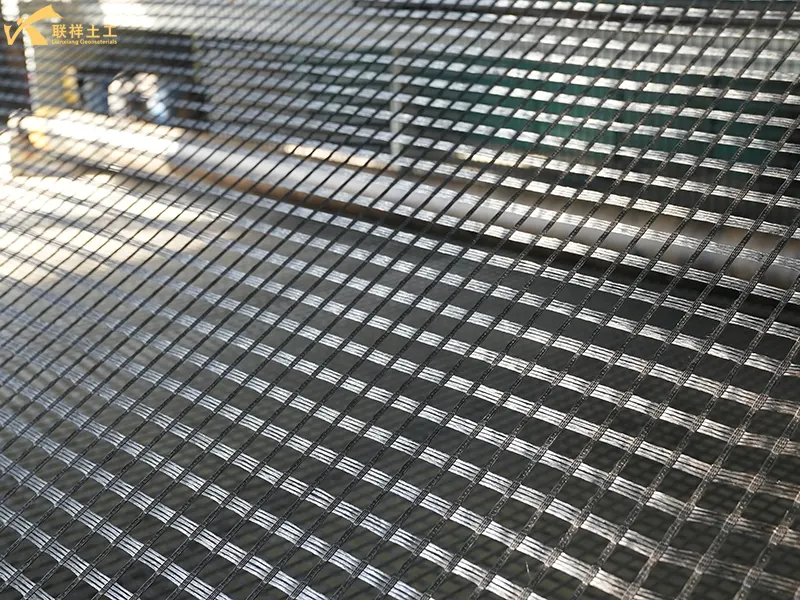

Fiberglass geogrids are rigid geosynthetic materials made primarily from untwisted fiberglass roving, through warp knitting and special coating treatment. Essentially, it is a high-strength, low-elongation mesh-like "skeleton." Its core material (fiberglass) provides extremely high tensile strength and modulus, but its inherent properties are poor, it is not wear-resistant, and it is easily broken. Its outer layer (special coating) is usually modified bitumen or polymer, primarily serving to protect, bond, and enhance anti-aging and chemical corrosion resistance.

2. Raw Material Costs (Basic Pricing Anchor)

Raw materials are always the most important factor determining product price. We must believe in the principle of "you get what you pay for." If products that look similar have vastly different prices, you should be sure that their raw materials are significantly different. The same applies to fiberglass geogrids. Whether the fiberglass has undergone purity enhancement and alkali-resistant treatment will greatly affect the price. Below, we will explain this in detail using a table.

| Cost Structure | Influencing Factors | Price Fluctuation Range |

| Fiberglass Yarn Cost | Purity, strength, and alkali resistance of E-glass fiber (main raw material); price fluctuations of upstream raw materials (quartz sand, soda ash, limestone) and energy | Accounts for 30%-40% of total cost; for every 10% price fluctuation, the price of the final product changes by 5%-8% |

| Coating Material Cost | Quality of coating materials such as modified asphalt, epoxy resin, and polyester resin; weather resistance and adhesion requirements | High weather-resistant modified resins cost 20%-30% more than ordinary coating materials |

| Energy and Labor | Natural gas and electricity consumption (accounts for 20%-30% of cost); production personnel salaries | For every 15% increase in energy prices, product costs increase by 3%-5% |

3. Specifications (Direct Cost Differences)

Product specifications are the second largest factor determining price. Different projects have different performance requirements, necessitating different specifications, which leads to price differences. For example, higher tensile strength results in a higher price. The following table provides a detailed explanation.

| Parameter Dimensions | Influencing Logic | Price Impact |

| Grammage | Fiberglass usage per unit area; higher grammage requires more material | 200g/㎡→400g/㎡, unit price increases by 30%-80% |

| Tensile Strength | Unidirectional/Bidirectional strength grades (20kN/m-150kN/m); higher strength requires thicker yarn or higher weaving density | For each strength grade increase, unit price increases by 10%-25% |

| Mesh Size | Smaller mesh (e.g., 12mm×12mm) requires higher weaving density, more labor and material consumption | Reducing mesh size from 50mm×50mm to 15mm×15mm increases unit price by 20%-40% |

| Width | Standard width (4m) has a 10%-20% lower unit cost than narrow width (1m); customized width increases waste | Special widths (e.g., 6m) increase price by 10%, narrow widths (< 2m) increase cost by 15% |

| Special Features | Self-adhesive layer (nail-free fixing), composite geotextile/membrane, freeze-thaw resistant treatment | Self-adhesive versions increase price by 15%-20%, composite versions increase price by 20%-30% |

4. Manufacturing Process (Source of Performance Premium)

The manufacturing process is also a crucial factor determining price. Different manufacturing processes result in products with significantly different performance characteristics. For example, warp knitting and ordinary knitting differ greatly in tensile strength. Furthermore, the coating treatment of the fiberglass surface, etc., all contribute to increased costs, and consequently, product quality. Below, we present a table illustrating these factors.

| Process Type | Features | Price Differences |

| Warp Knitting Process | Oriented structure, fully utilizes yarn strength, high tensile strength, good creep resistance | 10%-15% higher than ordinary knitting process |

| Biaxial Tensile Process | Uniform mesh, stable strength, suitable for high-requirement projects | 5%-10% higher than warp knitting process |

| Surface Treatment | Silane coupling agent (improves adhesion to asphalt), asphalt coating (aging resistance), PVC coating (corrosion resistance) | Special treatment increases unit price by 10%-30% |

| Composite Process | Composite with geotextile/membrane to enhance drainage and isolation functions | Composite products are 20%-40% higher than single geogrids |

5. Procurement and Market Factors (Marginal Adjustment Items)

Another factor is the price discrepancy caused by procurement process and market factors. For example, in terms of purchase volume, large-volume orders are definitely cheaper than small-volume orders. Also, market factors play a role; less market competition will result in slightly higher prices. However, these factors are only influencing, not critical. Let's take a closer look below.

| Influencing Factors | Mechanism of Action | Price Adjustment Range |

| Purchase Quantity | Large batches (tens of thousands of square meters) enjoy bulk discounts; small batches (below thousands of square meters) have higher fixed cost amortization | 5%-15% discount for purchases over 5000 square meters; 10%-20% premium for purchases under 1000 square meters |

| Brand and Certification | Well-known brands (such as Shandong Lianxiang) have strict quality control and possess ISO and GB/T certifications | Branded products are 5%-10% more expensive than those from smaller manufacturers |

| Logistics Costs | Transportation distance, mode (road/sea) and loading/unloading requirements | Long-distance transportation costs account for 5%-20% of the total price, and can reach 30% in remote areas |

| Market Supply and Demand | Prices rise when demand is concentrated during the peak infrastructure season; competition intensifies when supply exceeds demand | Prices rise 5%-15% during peak season; prices fall 3%-10% during off-season |

6. Technical Standards and Application Scenarios

Custom production is required for products with special requirements, which may increase costs slightly.

- Technical Standards: Products conforming to standards such as GB/T 17689-2008 and JTG/TD32-2012 will have increased testing costs by 2%-5%.

- Application Scenarios: Road engineering (standard price), bridge engineering (requiring higher strength, premium 10%-20%), airport runways (special specifications, premium 30%-50%)

7. Price Reference Range (December 2025)

The following prices are for reference only. Please contact the distributor or manufacturer for actual prices.

| Product Type | Specifications | Unit Price (RMB/㎡) | Equivalent to RMB per Square Foot |

| Ordinary Warp-Knitted Grating | 300g/㎡, Bidirectional 40kN/m, 25mm Mesh | 0.90-1.20 | 0.084-0.112 |

| Standard Bidirectional Grating | 300g/㎡, Bidirectional 50kN/m, 25mm Mesh | 1.20-1.50 | 0.112-0.140 |

| High-Strength Grating | 400g/㎡, Bidirectional 80kN/m, 15mm Mesh | 1.80-2.50 | 0.167-0.232 |

| Self-Adhesive Grating | 300g/㎡, Bidirectional 50kN/m, Self-Adhesive Layer | 2.50-3.30 | 0.232-0.307 |

8. Procurement Decision Recommendations

- 1. Lock in core parameters: Clearly define basis weight, tensile strength, mesh size, and width to avoid "using high specifications for low-end applications."

- 2. Bulk centralized procurement: Consolidate requirements from multiple bidding sections to strive for a 5%-15% bulk discount.

- 3. Balance logistics costs: Prioritize nearby manufacturers or suppliers that support full-truckload delivery.

- 4. Verify testing reports: Ensure products meet industry standards, focusing on tensile strength and alkali resistance indicators.

Through the above discussion, we should have a basic understanding of the price per square foot of fiberglass geogrid. We hope this will be helpful for your future product procurement. Lianxiang Geotechnical has been engaged in the production, sales, and R&D of fiberglass geogrid for many years. If you have product needs, please call us. Our sales team will provide an accurate quote per square foot based on your specified basis weight, tensile strength, mesh size, width, and purchase quantity.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188