- Description

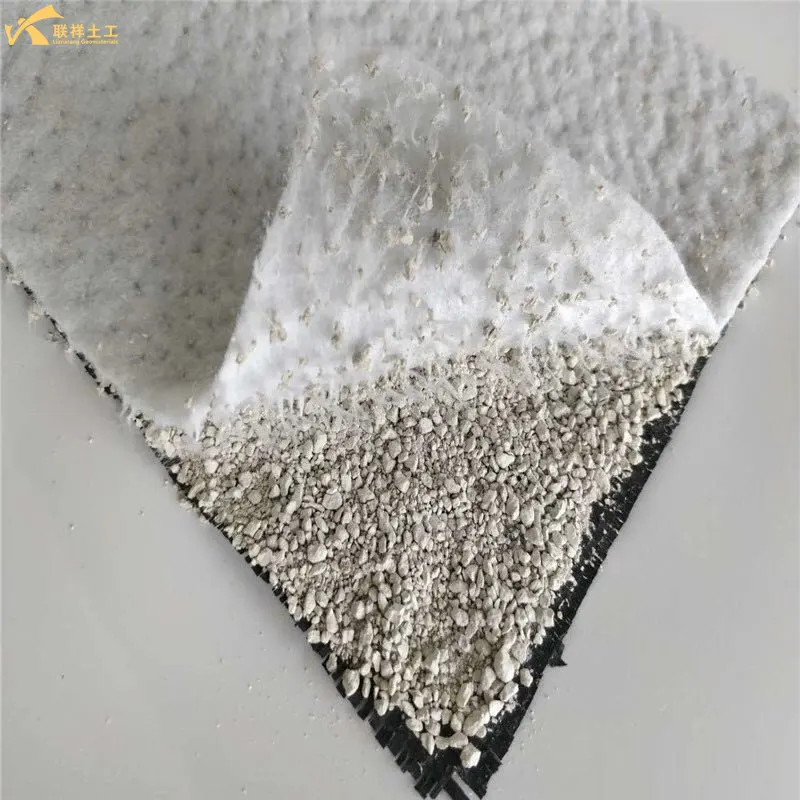

GCL Sodium Bentonite Clay Liner (Geosynthetic Clay Liner, also known as GCL), is a new type of geosynthetic material. It is a blanket-like waterproof (or anti-seepage) membrane composed of highly expansive sodium bentonite particles packed between specially formulated geotextiles (usually woven or non-woven). The membrane is formed by needle punching, bonding, or other methods.

I. Basic Introduction

1. Core Structure and Composition

A typical needle punched sodium bentonite blanket typically consists of three layers:

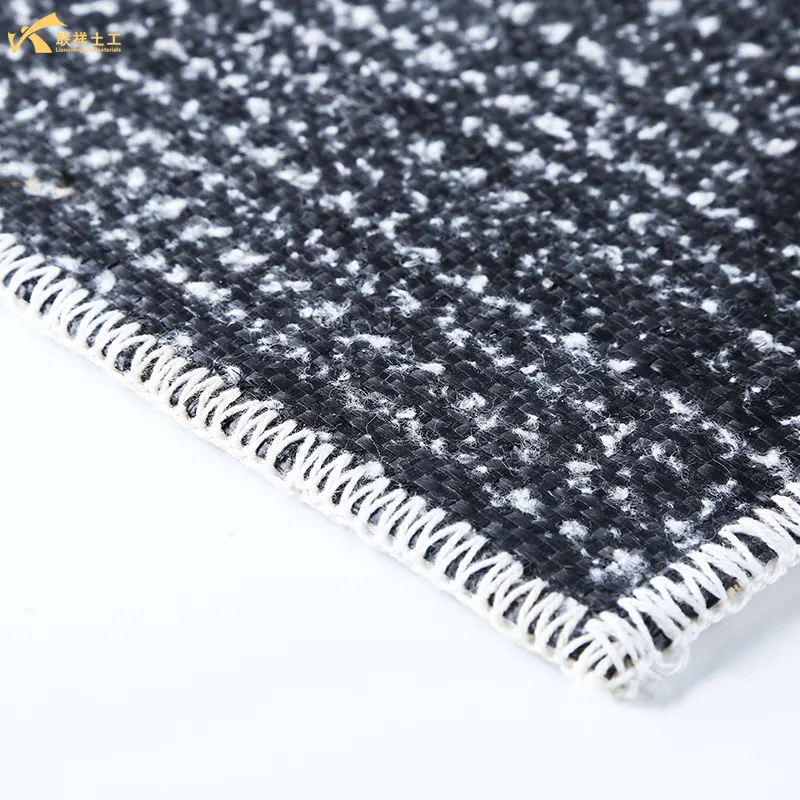

- Upper Layer: Non-woven geotextile - provides protection, filtration, and reinforcement, allowing water vapor to pass through while maintaining a bond with the bentonite.

- Core Layer: Natural sodium bentonite - the core waterproofing material.

- Lower Layer: Woven or non-woven geotextile - provides strength and maintains contact with the foundation during installation.

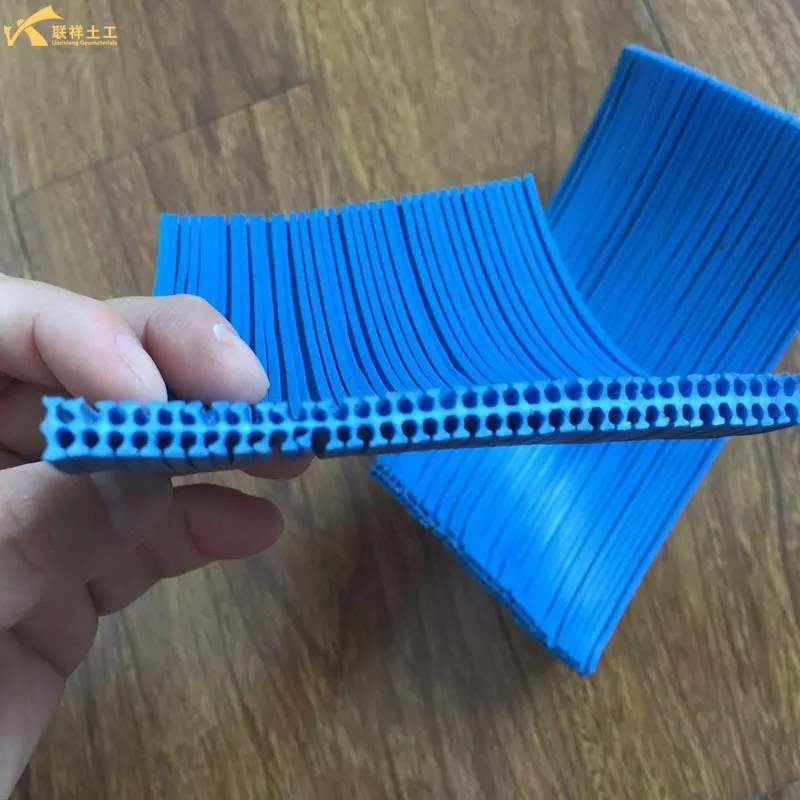

Through a needle-punching process, the fibers tightly connect the upper and lower geotextile layers to the bentonite layer in the middle. Even under certain external impacts or deformation, the bentonite is unlikely to fall off or shift.

2. Core Waterproofing Mechanism: The Self-Healing Property of Sodium Bentonite

This is the most remarkable and critical feature of GCL.

- Water Swelling: Sodium bentonite has extremely high swelling properties. Upon contact with water, it can absorb water to more than five times its dry weight, forming a dense, gel-like, low-permeability waterproof layer.

- Self-Healing: If punctures or damage occur during construction or use, the surrounding bentonite will migrate into the cracks or holes upon contact with water, automatically repairing the damage and maintaining its waterproof integrity. This is a significant advantage over traditional waterproofing materials (such as HDPE membranes).

- Permanent Waterproofing: Bentonite's waterproofing properties are permanent, as long as it is not contaminated by chemicals that alter its properties.

3. Key Features and Advantages

- Environmentally friendly: Made primarily of natural minerals, it is non-toxic, odorless, and pollution-free.

- Easy to apply: Lightweight and supplied in rolls, it allows for flexible and easy installation, requiring no large equipment, fast installation, and no curing period.

- Freeze-thaw and weather resistance: Insensitive to climate change, it does not become brittle at low temperatures.

- Wet-dry cycle resistance: Even after shrinking due to drying, it will re-expand and restore its waterproof properties upon contact with water.

- High performance-price ratio: The overall cost is lower than many traditional waterproofing materials.

- Good density: Sodium bentonite forms a high-density membrane under water pressure. At a thickness of approximately 3mm, its water permeability can be reduced to less than α×10-11 m/sec, equivalent to 100 times the density of 30cm thick clay, and it exhibits excellent self-water retention.

- Long-lasting waterproofing: As a natural inorganic material, sodium bentonite does not age or corrode, and offers excellent durability.

- Easy Construction: No heating or gluing is required; only bentonite powder, nails, washers, and other materials are used for connection and fixing. Post-construction inspection and maintenance are easy, the construction period is short, and it is not restricted by the construction temperature, even in temperatures below 0°C.

- Self-Healing Properties: Sodium bentonite has a strong ability to swell in contact with water, capable of repairing cracks on the concrete surface within 2mm, integrating the waterproofing material with the object.

4. Performance Indicators (Key Parameters)

- Bentonite Swelling Index (ml/2g): ≥24, a core indicator for measuring bentonite's ability to swell in contact with water.

- Waterproofness (Permeability Coefficient cm/s): ≤5×10⁻¹¹, equivalent to an equivalent permeability coefficient of 10⁻⁹ cm/s, indicating excellent waterproofing performance.

- Peel Strength (N): Reflects the ability of the needle-punched fibers to lock the bentonite, preventing soil loss.

- Breaking Strength (kN/m): Reflects the overall tensile strength of the material. Bentonite mass per unit area (g/m²): For example, 4500g/m², 5000g/m², etc., directly affects waterproofing effectiveness and durability.

II. Key Attribute

| Attribute Category | Specific Attributes | Definition and Significance | Typical Standards/Values |

| Physical Properties | Mass per Unit Area | Total weight per square meter, affecting performance and cost | ≥ 4000 g/m² (e.g., 5000 g/m²) |

| Thickness | Thickness at a specific pressure, affecting buffering capacity | ~6 mm (@2 kPa) | |

| Hydraulic Properties | Bentonite Swelling Index | Swelling capacity of the core material in contact with water | ≥ 24 mL/2 g** (ASTM D5890) |

| Permeability Coefficient | Direct reflection of waterproof performance, lower values are better | ≤ 5×10-11 m/s(after hydration) | |

| Mechanical Properties | Peel Strength | Resistance to bentonite shedding, related to durability | ≥ 65 N(ASTM D6496) |

| Tensile Strength | Resistance to breaking, impacting slope stability | 10 - 25 kN/m | |

| Durability | Chemical Compatibility | Resistance to chemical liquids is a key application limitation | Requires testing based on specific environment |

| Wet-Dry Cycle Durability | Resistance to repeated drying and hydration | High-quality product recovery |

III. Main Application Areas

Due to its unique advantages, GCL is widely used in various projects requiring anti-seepage, sealing, and isolation.

1. Environmental Protection Engineering (the most important area)

- Landfills: Used as the bottom liner and top capping layer to prevent leachate from contaminating groundwater and the escape of harmful gases. It is often used in combination with HDPE membrane to form a "double lining" system.

- Hazardous waste disposal sites: These sites have extremely high requirements for anti-seepage, and GCL is a core anti-seepage material.

- Sewage treatment ponds, artificial lakes, and landscape water bodies: Prevent sewage or lake water from seeping into the ground.

- Industrial tailings ponds and red mud dumps: Prevent the leakage of wastewater containing heavy metals and other harmful substances.

2. Water Conservancy Projects

- Rivers, Canals, and Reservoirs: Used as anti-seepage linings for riverbeds and canal bottoms to reduce water loss.

- Dams and Levees: Used for anti-seepage in core walls or inclined walls, or for anti-seepage reinforcement of existing projects.

3. Construction Projects

- Basements and Underground Garages: Used as a waterproofing layer for floor slabs and side walls, especially suitable for planted roofs, where its resistance to plant root penetration surpasses many other materials.

- Roof Gardens: Excellent waterproofing and root penetration resistance.

- Subways and Tunnels: Used for waterproofing and drainage systems behind tunnel linings.

4. Other Projects

- Underground Oil Storage Tanks and Gas Stations: Used as a secondary anti-seepage lining to prevent oil leaks and soil contamination.

- Agriculture: Used for anti-seepage in reservoirs and irrigation channels.

- Municipal Engineering: Used for underground pipeline corridors, fire water tanks, etc.

IV. Construction Precautions

- 1. Base Preparation: The base must be flat, solid, and free of sharp objects (such as stones and tree roots) to prevent the waterproof blanket from puncturing. A layer of sand or well-graded fine soil is usually laid as a protective layer.

- 2. Laying and Overlapping:

- The bentonite surface should be laid facing downward (the water-facing side).

- The longitudinal and transverse overlap widths between blankets are generally required to be ≥300mm.

- At the overlap, dry bentonite powder (a continuous strip 10mm wide and 5mm high) should be evenly sprinkled throughout the overlap gap to ensure a tight seal.

- 3. Anchoring: Specialized battens and concrete nails are required for anchoring and sealing at edges and corners of the structure.

- 4. Protection: After laying, the GCL should be covered with backfill soil as soon as possible (usually within 48 hours) to prevent premature water loss and shrinkage or degradation due to prolonged ultraviolet radiation. The backfill soil must not contain sharp impurities.

- 5. Waterproofing: During construction and before covering, GCL should be protected from rainwater. If rain does occur, drainage measures must be taken and construction can resume only after the surface has dried naturally.

Specification

| Testing Item | Testing Methods | Technical Indexes |

| Expansion Coefficient | ASTM D 5890 | ≥27ml/2g |

| Fluid Loss | ASTM D 5891 | ≤18ml |

| Bentonite quality in Unit area | ASTM D 5993 | ≥4.8kg/m2 |

| Tension Strength | ASTM D 4632 | ≥400N |

| Peeling Strength | ASTM D 4632 | ≥75N |

| Indicating flow | ASTM D 5887 | ≤1*10-8m3/m2/sec |

| Penetrability | ASTM D 5887 | ≤5*10-9cm/sec |

| Tension Strength after Wetting | ASTM D 5321 | ≥24Kpa typical |

Summary

GCL sodium bentonite waterproofing blanket is a highly effective anti-seepage material that combines the environmental friendliness of natural mineral materials, excellent self-healing waterproofing properties, and convenient construction. It has become an indispensable key material in fields such as environmental protection, water conservancy, and underground construction. Especially when combined with materials such as HDPE membrane in a composite lining system, it can provide a reliable anti-seepage effect that is "1+1 greater than 2."

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188