- Description

Capillary drainage board is a new type of high-efficiency drainage material widely used in building waterproofing, landscaping projects, and underground structures. Through its ingenious physical structure, it solves many of the pain points of traditional drainage methods (such as pebble blind drains).

I. Core Definition

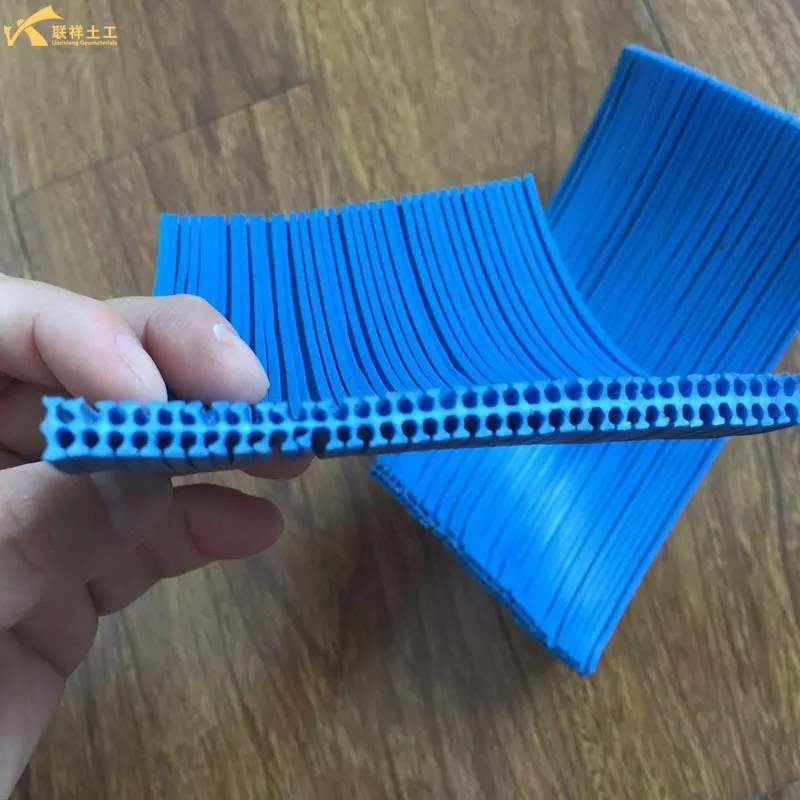

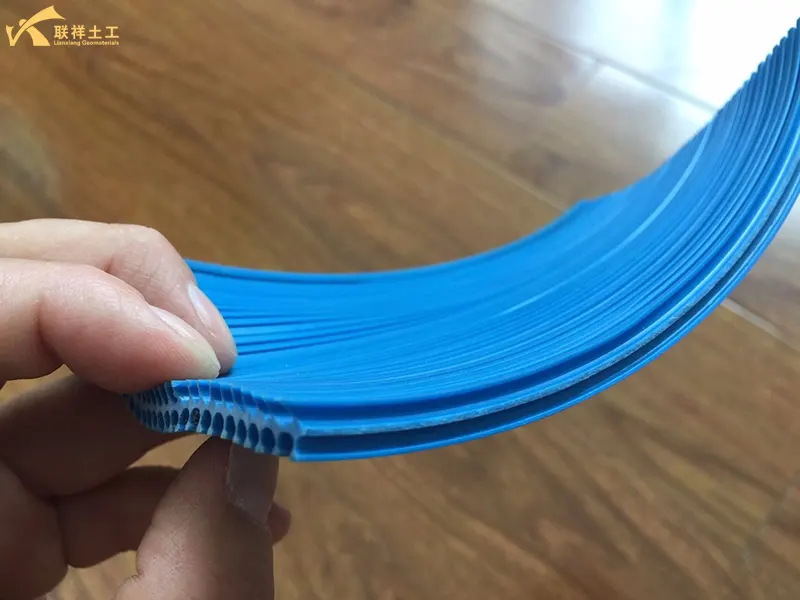

Capillary drainage board, also known as "waterproofing and drainage protection board" or "siphon drainage board," is a plastic sheet made of materials such as high-density polyethylene (HDPE) or polypropylene (PP). Its core feature is that one side of the board is designed with dense capillary drainage channels or protrusions, achieving active and efficient drainage, moisture-proofing, and pressure reduction functions through capillary action and the siphon principle.

II. Core Structure and Working Principle

1. Physical Structure:

- Protrusion/Columnar Layer: On the side facing the waterproofing layer or soil, there are regularly arranged conical, cylindrical, or ribbed protrusions. These protrusions form an elevated drainage channel.

- Capillary Drainage Channels/Filter Layer: Very fine grooves are designed on the top of the protrusions or on the board surface, or it is covered with non-woven fabric.

- Filtration: Prevents soil and particles from clogging drainage channels.

- Capillary action: Water is "drawn" up through the micropores between the non-woven fibers (capillary action) and guided into the drainage channels.

- Drainage space: The gaps between the protrusions create a continuous, unpressurized, rapid drainage space.

2. Working principle (the key to "active drainage"):

- Collection: Groundwater or infiltrated water passes through the soil or backfill layer and is filtered and "absorbed" by the non-woven fabric on the surface of the capillary drainage board.

- Guidance: Under the influence of capillary action and gravity, water is introduced into the elevated drainage channels between the protrusions.

- Discharge: Because the drainage channels are continuous and have a certain slope, water quickly flows to the pre-set collection well or drain pipe and is efficiently discharged by the siphon effect, thus creating a pressureless or low-pressure state outside the waterproof layer.

III. Main Types

Based on structure and application, they are mainly divided into two categories:

1. PSH (Protective Capillary Drainage Board):

- Structure: Protrusions face upwards, surface covered with needle-punched non-woven fabric.

- Applications: Primarily used for waterproofing and drainage of roof slabs, side walls, and floor slabs in underground engineering projects. Applied to the outside of the waterproof layer, it protects the waterproof layer from damage by backfill soil and guides water away. This is the most common form of basement drainage.

- Figurative Description: Like putting a "moisture-proof and water-wicking underwear" on the building.

2. PSP (Drainage-Type Capillary Drainage Board):

- Structure: Protrusions face downwards, non-woven fabric on top of the board.

- Applications: Primarily used for rooftop greening, garage roof planting, plaza drainage, etc. The protrusions face downwards, contacting the structural slab to form a drainage layer. Soil is placed on top for planting, and excess water is filtered through the non-woven fabric and flows into the drainage layer for removal.

- Figurative Description: Like placing a "drainage tray" under the planting soil.

IV. Main Specifications and Models

Common Specifications (Taking PVC Capillary Drainage Board as an Example):

| Parameter | Common Values | Description |

| Thickness | 2.0±0.3mm | National Standard Recommended Thickness |

| Width | 200-300mm | Customizable, commonly 1000mm |

| Length | 50-100m/roll | Convenient for construction and transportation |

| Trench Spacing | 2-5mm | Affects water absorption efficiency |

| Drainage Capacity | 10-30L/(s·m²) | Varies depending on model and slope |

| Tensile Strength | ≥15kN/m | Meets soil covering and construction requirements |

V. Core Advantages (Compared to Traditional Pebble Drainage)

| Characteristics | Capillary Drainage Board | Traditional Pebble/Ceramic Aluminum Cement Drainage |

| Drainage Efficiency | Extremely high, relies on siphon and capillary action for active drainage | Relatively low, relies on gravity infiltration for passive drainage |

| Drainage Capacity | Large drainage cross-section, not easily clogged | Drainage cross-section is easily blocked by soil |

| Compression Resistance | Strong, HDPE material can withstand high backfill soil pressure | Moderate, may settle under long-term loads |

| Weight | Extremely light, convenient for transportation and construction | Extremely heavy, high transportation and construction costs |

| Thickness | Thin (usually 0.8-2.0cm), saves space | Thick (at least 20-30cm), occupies a lot of space |

| Construction Difficulty | Simple, just splice and lay | Complex, requires handling, laying pebbles and geotextile |

| Overall Cost | Slightly higher material unit price, but saves space, labor, and transportation, resulting in low overall cost | Low material unit price, but extremely high hidden costs (space, labor, transportation) |

VI. Main Application Areas

1. Underground Construction Engineering:

- Waterproofing and drainage for basement roof slabs, side walls, and floor slabs.

- External drainage for tunnel and subway linings.

2. Municipal and landscaping projects:

- Drainage and water storage for roof gardens and underground garage roof planting areas.

- Drainage for sports fields, golf courses, etc.

3. Road and traffic engineering:

- Seepage prevention and drainage for highway and railway subgrades, replacing traditional gravel layers.

4. Others:

- Drainage behind retaining walls, dam drainage, etc.

VII. Construction Key Points

- 1. Substrate treatment: Flat, firm, and free of sharp objects.

- 2. Laying direction: Generally, the side covered with non-woven fabric (filter layer) faces the water source (such as soil), and the raised side faces the waterproofing layer or structural slab.

- 3. Overlapping and fixing: The boards are firmly connected by overlaps or special fasteners, and the joints are sealed with tape to prevent soil intrusion. Fixing to the wall or ground is required.

- 4. System Connection: Water within the drainage board must be effectively channeled into surrounding blind drainage pipes or sump pits to form a complete drainage system.

- 5. Backfill Protection: Backfilling should be carried out promptly after installation to prevent aging due to sun exposure. Care should be taken during backfilling to avoid direct compaction by heavy machinery.

Summary

Capillary drainage boards are a revolutionary drainage technology in modern engineering. With their significant advantages of being lightweight, efficient, space-saving, and easy to install, they have gradually replaced traditional pebble drainage layers, becoming an indispensable key material in building waterproofing and drainage, landscaping projects, and underground infrastructure, effectively solving problems such as leakage, moisture prevention, and structural buoyancy.

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188