- Description

Staple needle punctured non-woven geotextile are made from polyester or polypropylene, arranged in random directions and mechanically entangled (needling) during the manufacturing process. This nonwoven design provides a higher water permeability, allowing water to penetrate more easily. This type of product is commonly used to separate clay layers from drainage layers to protect the liner from damage. It is one of the most widely used basic geosynthetics in civil engineering, hydraulic engineering, and environmental engineering.

Manufacturing Process:

The staple needle punctured non-woven geotextile adopts the mechanical entanglement staple fiber needle-punching process. The specific process flow is as follows.

- 1. Fiber Preparation: Primarily using polyester (PET) or polypropylene (PP) as the main raw material, these polymers are melted, spun, and cut into staple fibers.

- 2. Opening and Carding: The staple fibers are dispersed in an opener and then combed into a web (fiber web) with random directions but uniform thickness.

- 3. Needle-Punching: This is the most critical step. Driven by a needle-punching machine, thousands of barbed needles repeatedly pierce the web. The barbs of the needles drive some fibers downward, causing them to interweave, entangle, and connect.

- 4. Reinforcement and Forming: After countless needling cycles, the originally loose fiber web is transformed into a tightly structured, cloth-like material with a certain thickness, strength, and toughness.

- 5. Finishing: Depending on the needs, singeing, calendering, and impregnation may be performed to modify the surface characteristics or enhance certain properties (such as filtration accuracy).

Features

- Three-Dimensional Pore Structure: The fibers are arranged in a three-dimensional, staggered pattern, forming countless tiny, interconnected pores. This provides excellent water permeability and filtration properties, allowing water to pass while effectively blocking soil particles.

- Excellent Mechanical Properties: The needling process tightly entangles the fibers, giving the material excellent tensile strength, tear resistance, puncture resistance, and deformation adaptability.

- Durability and Corrosion Resistance: Chemically stable, resistant to acids, alkalis, insects, and mold, it has a long service life in soil. Easy to construct: Lightweight, packaged in rolls, and easy to cut and lay.

Functions

- 1. Isolation: Prevents soil layers with different characteristics (such as roadbed and soft foundation) from mixing, maintaining the structural integrity of each.

- 2. Filtration: Allows water to flow smoothly from fine-grained soil to coarse-grained soil, effectively preventing excessive loss of fine soil particles and preventing pipe bursts.

- 3. Drainage: Utilizing its three-dimensional pore structure, it forms drainage channels within the soil, collecting and discharging excess liquid or gas.

- 4. Reinforcement: Distributes loads, improves the tensile and shear strength of the soil, and enhances the stability of soft foundations.

- 5. Protection: Serves as a cushion layer to prevent other anti-seepage materials (such as geomembranes) from being punctured by sharp objects.

Application

Due to its versatility and cost-effectiveness, staple needle punctured non-woven geotextile are widely used in the following engineering scenarios:

1. Highway and Railway Engineering

- Application: Used as an isolation layer between the roadbed and soft subgrade, preventing rock subsidence and soil upwelling, maintaining roadbed thickness and bearing capacity, and extending road life.

- Function: Isolation, reinforcement, and drainage.

2. Water Conservancy Projects (Embankments, River Channels)

- Application:

- Filter Layer: Used on the backwater side of earth-rock dams, riverbanks, and slope protection as a filter layer to prevent soil erosion and ensure the smooth drainage of seepage water.

- Slope Protection Underlay: Laid beneath the paving stones or concrete slabs to prevent the base soil from being washed away by water.

- Function: Filtration, drainage, and protection.

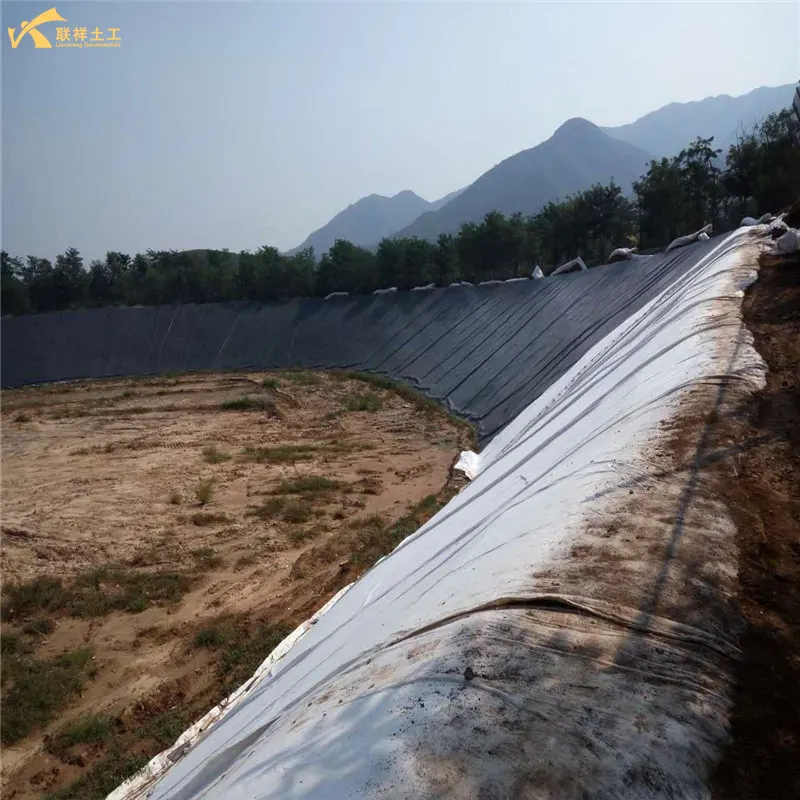

3. Environmental Protection Projects (Landfills)

- Application:

- Base Layer: Laid on the bottom and slopes of landfills, it serves as a protective layer for the geomembrane to prevent punctures. Leachate Collection and Drainage Layer: Used in conjunction with drainage nets to filter and drain leachate generated by landfill.

- Cover System: Serves as a drainage and reinforcement layer within the final cover layer.

- Functions: Protection, filtration, and drainage.

4. Municipal and Construction Engineering

- Application: Used in underground drainage systems, roof garden drainage, foundation treatment, and other applications, providing filtration and drainage.

5. Agriculture and Gardening

- Application: Used in farmland drainage ditches, orchard weed control sheets, and Geotextile bag, achieving water permeability and soil conservation.

Advantages and Limitations

Advantages:

- Cost-effective and widely applicable.

- Comprehensive functions (isolation, filtration, drainage, reinforcement).

- Good flexibility, adaptable to uneven settlement.

Limitations:

- Compared to spunbond (filament) geotextiles, their initial tensile strength is generally lower.

- For applications requiring extremely high strength reinforcement (such as reinforced earth retaining walls), warp knitted or woven geotextiles are typically used.

Specification

| No. | Item | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remark |

| 1 | Mass per unit, g/㎡ | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

| 2 | Thickness,mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

| 3 | Width deviation,% | -0.5 | |||||||||||

| 4 | Break strength,kN/m≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD&CMD |

| 5 | Break elongation,% | 25-100 | |||||||||||

| 6 | CBR puncture strength ,kN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

| 7 | Effective pore size O90(O95),mm | 0.07-0.2 | |||||||||||

| 8 | Vertical osmotic coefficient,cm/s | K x (10-1 ~ 10-2) | K=1.0~9.9 | ||||||||||

| 9 | Tear strength, kN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD&CMD |

Conclusion

Staple needle punctured non-woven geotextile is a classic geosynthetic material produced through physical and mechanical methods. Its unique three-dimensional fiber network structure is the core of its multiple functions, including filtration, drainage, isolation, and protection. From the roads beneath our feet to the rivers nearby, from massive landfills to ordinary rooftop gardens, this "unsung" foundational material plays an indispensable role in modern engineering construction, a key component in ensuring project safety, durability, and stability.

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188