- Description

Dimpled plastic drain sheet are made from polymer materials through extrusion and adsorption processes. They effectively remove gases and liquids in three dimensions. This versatile material easily removes moisture and provides thermal and vibration isolation. In civil engineering, they are widely used in building roof systems, elevated bridges, man-made shaft ventilation, basement waterproofing systems, indoor surface insulation and moisture protection, and drainage protection for highway and railway tunnels. In today's increasingly scarce urban land, space, and material resources, plastic concave drain panels offer the most valuable protection.

I. Basic Introduction

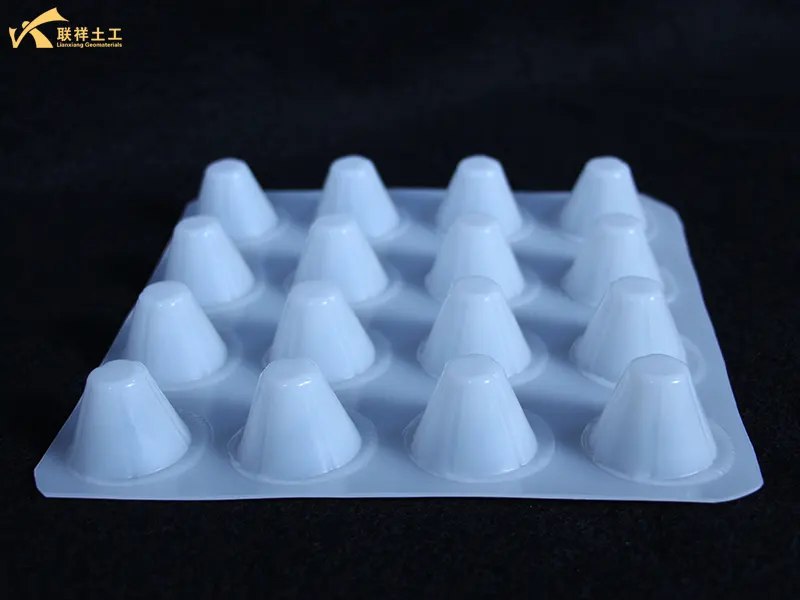

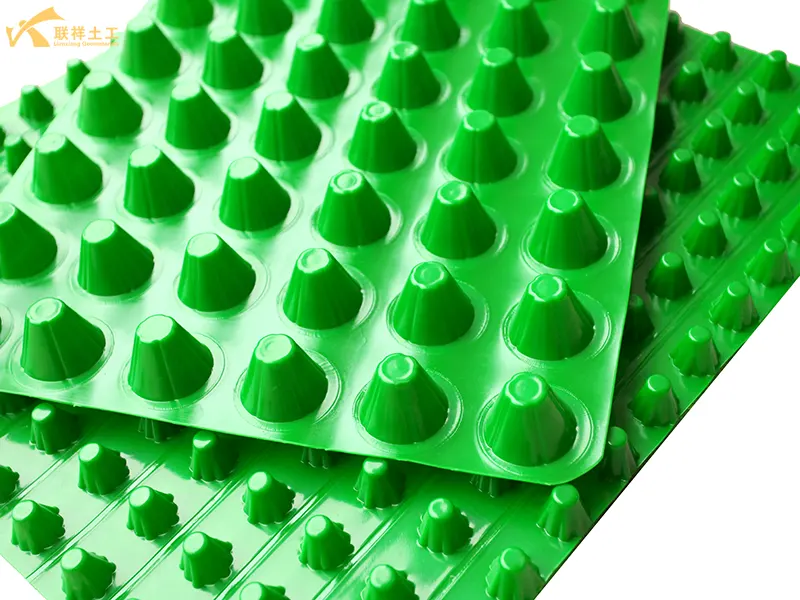

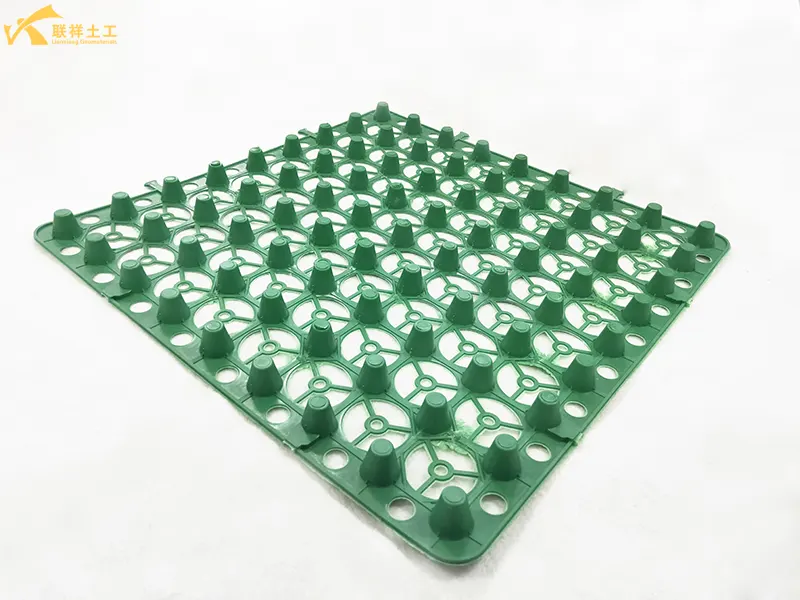

Dimpled plastic drain sheet, also known as drainage protection panels or concave-convex drain panels, are sheets made from pressed high-density polyethylene (HDPE) or polypropylene (PP) plastic. Their core feature is a regularly patterned pattern of raised points (platforms) on one side and a flat surface (or with a varying pattern) on the other.

1. Core Structure and Components

1.1. Raised Point Surface (Platform):

- Function: They form an elevated layer, creating a continuous void space. This is the core function of the drain panel. These raised points absorb pressure from the upper layers (such as soil, concrete, and masonry), ensuring that the drainage channels beneath them remain unobstructed and uncompressed under all pressures.

- Design: The raised points are typically truncated, cylindrical, or square, with heights ranging from 5mm to 20mm or even higher, depending on the drainage requirements.

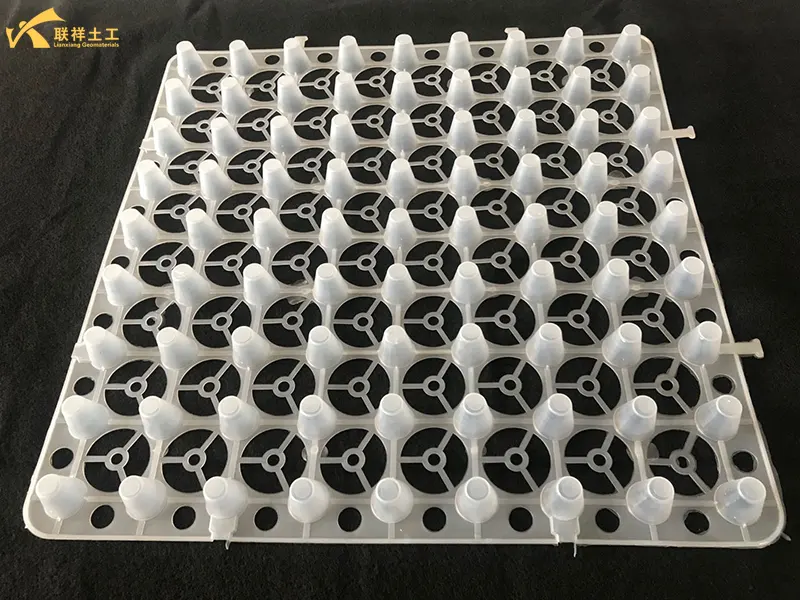

1.2. Base (Flat or Membrane):

- Some hydrophobic sheets have a smooth surface opposite the raised points, facilitating installation and bonding.

- Another common design is a composite hydrophobic sheet, in which a layer of nonwoven geotextile is thermally bonded to the raised surface. This geotextile performs a crucial filtering function, preventing soil particles from entering the drainage channels with the water flow and causing blockage, thus achieving an integrated "filtration, drainage, and protection" function.

2. Working Principle

The working principle of the dimpled plastic drain sheet can be summarized as "guidance, drainage, and protection":

- 2.1. Diversion: When water (such as rainwater or seepage water) penetrates the hydrophobic plate surface, it passes through the geotextile filter layer and enters the elevated drainage voids formed by the raised points.

- 2.2. Drainage: Water flows freely within the elevated layer by gravity and is directed into pre-designed drainage ditches, blind drains, or wells for systematic collection and drainage.

- 2.3. Protection: The hard raised point surface forms a strong protective layer that effectively resists impact and damage from backfill, concrete static pressure, and construction loads, protecting the underlying waterproofing layer or building structure.

- 2.4. Waterproofing Layer Maintenance: In applications such as green roofs and underground garage roofs, it quickly drains accumulated water, eliminates hydrostatic pressure, and significantly reduces the risk of waterproofing leakage.

3. Main Features and Advantages

- High Drainage Efficiency: The short drainage path and large drainage cross-section provide excellent drainage results.

- High Compressive Strength: The scientifically designed raised points distribute and withstand high loads, resulting in excellent compressive performance.

- Corrosion Resistance and Durability: The HDPE/PP material is chemically resistant and resists plant root penetration, resulting in a long service life.

- Easy Installation and Low Overall Cost: Lightweight and supplied in rolls, it is quick and easy to install, reducing the thickness and load of traditional pebble-ceramic drainage layers, saving time and material costs.

- Integrated Functionality: The hydrophobic board, combined with geotextiles, combines drainage, filtration, and protection.

II. Applications of Hydrophobic Boards

Dimpled plastic drain sheet have a wide range of applications, primarily focusing on their two core functions: drainage and protection.

1. Main Application Areas

1.1. Underground Waterproofing and Drainage

- Basement slabs and side walls: Installed outside the waterproofing layer, they serve as a protective and drainage layer, directing any infiltrating water to a collection well, creating an "active drainage" protection system and mitigating damage to the waterproofing layer caused by hydrostatic pressure.

- Underground garage roof (planting roof): This is the most classic application. It is laid above the waterproofing layer and covered with soil for planting. The hydrophobic plate quickly drains excess rainwater, preventing waterlogging and root rot in plant roots while protecting the waterproofing layer from backfill and root damage.

- Tunnel and subway projects: It is used for drainage behind the lining, directing seepage water from the rock and soil into the drainage ditch to ensure the safety of the tunnel structure.

1.2. Roof gardens and greening projects:

- The drainage layer used in green roofs replaces traditional expanded clay and crushed stone layers, significantly reducing roof loads, providing more efficient drainage, and facilitating maintenance.

1.3. Plazas, roads, and garden projects:

- In stadiums and plazas: It is laid beneath the base layer to drain surface water and prevent cracking and collapse caused by frost heave or water pressure.

- Road subgrade: It is used for soft subgrade treatment or shoulder drainage, accelerating subgrade consolidation and improving stability.

1.4. Other applications:

- Backside drainage of retaining walls: It reduces soil moisture content and mitigates damage to the wall caused by earth pressure.

- Building foundations: Used for drainage around foundations, keeping them dry.

- Landfills: Serves as a crucial component of the leachate collection and drainage layer.

2. Construction Process (Basement Roof Slab Example)

- 2.1. Base Layer Preparation: Complete the structural layer (concrete roof slab) and clean and level it.

- 2.2. Waterproofing: Lay high-quality waterproofing membrane or coating and protect it.

- 2.3. Laying the Drain Plate:

- Lay the composite drain plate (with geotextile) on the waterproof layer, geotextile side down (close to the base).

- Securely bond the plates with special lap tape or glue to prevent soil from entering the joints.

- 2.4. Laying the Non-Woven Fabric: If using drain plates without composite geotextiles, lay a non-woven geotextile over them as a filter layer.

- 2.5. Backfill:Backfill soil directly onto the geotextile and plant greenery.

III. Summary

Hydrophobic board is a highly efficient and versatile modern engineering drainage material. Its unique convex structure creates superior drainage and protection performance, perfectly resolving the issues of traditional drainage methods (such as pebble beds), such as excessive weight, low drainage efficiency, and clogging. In areas such as building waterproofing, landscaping, and underground engineering, it has become an indispensable key material for improving project quality, extending structural life, and achieving energy conservation and emission reduction.

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188