Exploring Future Functional Enhancement Directions and Market Demands of Geocells

The negative impacts of global economic development have already manifested in tangible problems. Natural disasters such as melting glaciers, desertification, landslides, and mudslides are occurring frequently. Therefore, addressing climate change has become a crucial issue for all humanity. Geocells play an irreplaceable role in mitigating natural disasters. Through their "constraint-reinforcement-anti-slip" mechanism, they can solve problems such as foundation settlement, slope instability, and soil erosion in geotechnical engineering, and are widely used in transportation, water conservancy, mining, and nature conservation. Lianxiang Geotechnical has always believed that technological development should not come at the expense of the environment. Technology and environmental protection can go hand in hand to perfectly realize the dream of sustainable development. Therefore, Lianxiang Geotechnical is investing heavily in the research and development of next-generation geocell products to better fulfill their mission in protecting the environment and mitigating natural disasters. Today, we will discuss the future functional improvements of geocells and explore market demands.

1. Current Industry Analysis

Global Market:

- The market size was approximately US$7-21 billion in 2024, with a projected CAGR of 5.8%-8.9% from 2025-2035, potentially exceeding US$28 billion by 2035.

- Demand is gradually increasing in Europe and the United States, especially in Europe, which experienced an earlier industrial revolution and is increasingly recognizing the importance of environmental protection.

China Market:

- The market size was approximately RMB 3.86 billion in 2023, reaching RMB 4.5 billion in 2024, with a stable annual growth rate of over 12%, and is projected to exceed RMB 18 billion by 2030.

- China contributes over 35% to the global market for eco-friendly geocells, and the market size is projected to exceed US$4.5 billion by 2025.

Problems:

- Existing geocell raw materials cannot be effectively applied in specialized fields, such as extremely cold, high-temperature, and acidic/alkaline environments, where applications often fail to achieve ideal results.

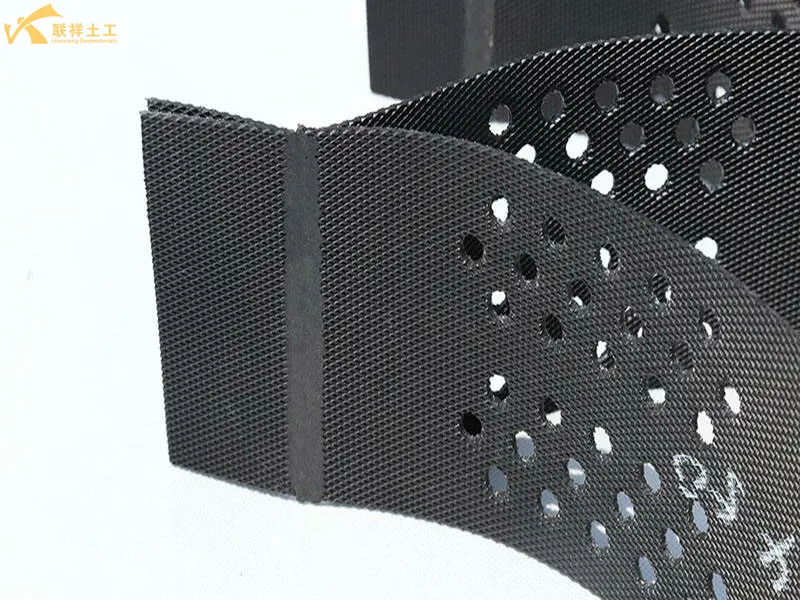

- Issues include peeling or slippage at welded joints, insufficient contact surface at joints, deformation of HDPE and other plastic geocells under long-term loads, and changes in stress distribution due to openings.

2. Core Development Directions

The development direction of geocells is summarized from feedback on practical problems. Lianxiang Geotechnical has a dedicated construction and after-sales service team. Whether it's problems encountered during construction or user feedback, we reliably report them to the company's R&D team. Our design engineers will determine improvement methods and future R&D directions based on these issues.

2.1. Material Innovation and High Performance

- Diversified Raw Materials: Expanding from traditional polypropylene (PP) and polyethylene (PE) to polyester (PET), nylon (PA), and even bio-based and biodegradable plastics to meet the needs of different engineering environments (such as acids, alkalis, ultraviolet radiation, and high temperatures).

- High-Performance Modification: By adding anti-aging agents, UV stabilizers, carbon black, etc., significantly improving the durability and service life of materials, enabling them to withstand design lifespans exceeding 50 or even 100 years.

- Composite Materials: Develop reinforced cell structures that are combined with geotextiles, geomembranes, and steel wire ropes to form an integrated "reinforcement-drainage-proofing" structure, achieving a synergistic effect greater than the sum of its parts.

2.2. Intelligent Structural Design and Manufacturing Processes

- Node Structure Optimization: Develop stronger and more reliable welding node technologies to improve the peel strength of nodes and the tensile strength of the overall structure.

- Differentiated Design: Produce cell structures with different weld spacings, heights, and wire thicknesses according to engineering needs, achieving "tailor-made" solutions rather than universal standard products, to achieve optimal cost-effectiveness.

- Intelligent Manufacturing: Introduce automated production lines and Industrial Internet of Things (IIoT) technology to improve production efficiency and product quality stability, while reducing energy consumption and costs.

2.3. Continuous Expansion and Deepening of Application Areas

- From "Hard" Engineering to "Soft" Ecology: The focus of applications is expanding from traditional hard infrastructure reinforcement such as highways, railways, and airports to large-scale ecological restoration and environmental protection fields, such as slope ecological greening, desertification control, mine reclamation, and riverbank protection. Here, geocells serve as both a stabilizing structure and a carrier for plant growth.

- Sponge City Construction: In sponge city facilities such as permeable pavements, rain gardens, and sunken green spaces, geocells act as a supporting framework for lightweight fillers, combining water storage, purification, and stabilization functions.

- Marine and Hydraulic Engineering: Used for coastline protection, breakwater reinforcement, and artificial island/reef foundation treatment, their flexible structure effectively dissipates energy and adapts to foundation settlement.

- Special Foundation Treatment: In extreme conditions such as ultra-high embankments, soft soil foundations, and permafrost regions, geocells provide effective solutions for distributed loads and lateral confinement.

2.4. Green and Sustainable Development

- Ecological Compatibility: Used in conjunction with vegetation mats and eco-bags, geocells create a favorable environment for plant growth, achieving harmony between engineering structures and the natural ecosystem.

- Recycling: Research is underway to use recycled plastics in the manufacture of geocells, reducing "white pollution" and aligning with the concept of a circular economy.

- Applications of Biodegradable Materials: In the initial stages of temporary projects or ecological restoration, biodegradable geocells are used. Once the plant roots have provided sufficient reinforcement, the geocells naturally degrade without secondary pollution.

3. Future Prospects

We can be confident in the future market demand. The application areas will become increasingly wider, and the demand will increase significantly. This is mainly because the current severe environmental impacts have posed enormous challenges to human survival, making climate change mitigation and natural disaster reduction a top priority for all countries.

3.1. Market Drivers and Opportunities

- Global Infrastructure Wave: Whether it's China's "New Infrastructure" and "Belt and Road Initiative," or the global infrastructure upgrades, all provide stable market demand for geocells.

- "Dual Carbon" Strategic Goals: China's "carbon peaking and carbon neutrality" goals have greatly promoted green and low-carbon engineering construction technologies. Geocells have significant advantages in reducing fill volume, saving building materials, reducing transportation energy consumption, and promoting ecological carbon sequestration, and will receive policy support.

- Addressing Climate Change: Geocells will play a crucial role in resilient infrastructure construction and post-disaster reconstruction in response to extreme weather events (such as floods and landslides) due to their rapid construction and significant effectiveness.

- Emerging Economy Development: Infrastructure construction in Southeast Asia, Africa, and the Middle East is booming, representing a huge market for geocell exports and international cooperation.

3.2. Technological Integration and Innovation Directions

- Intelligent Construction and Monitoring: The future may see "intelligent geocells" with embedded fiber optic sensors or RFID tags to monitor their stress, deformation, and internal environmental status in real time, providing data support for long-term health diagnosis and early warning of projects, achieving "permanent" engineering monitoring.

- Deep Integration with New Materials Science: Cutting-edge technologies such as nanomaterials and self-healing materials may be introduced to create "intelligent" geocells with stronger mechanical properties or the ability to self-repair minor damage.

- Standardization and Improvement of Design Theory: With the deepening of applications, relevant design specifications, construction procedures, and long-term performance databases will be further improved, driving the industry to shift from "experience-based" to "precise analysis-based" approaches, enhancing the confidence of designers and owners.

3.3. Potential Challenges

- Cost Pressure: The initial investment in high-performance new materials and intelligent manufacturing may lead to increased product costs, requiring a balance between performance and cost.

- Lagging Market Awareness and Standards: In some regions and fields, the understanding of geocells remains at the level of "cheap alternatives," and their systemic value is not fully recognized. The update speed of some design standards cannot keep up with the pace of product innovation.

- Long-Term Performance Data Accumulation: For the ultra-long-term (e.g., 100 years) performance of new materials and under extreme environments, longer-term data observation and verification are still needed.

4. Development Roadmap for the Next Five Years (2025-2030)

4.1. Short-Term (2025-2027):

- Large-scale application of biodegradable materials, increasing their share to 15%.

- Penetration rate of intelligent monitoring systems reaches 20%, with early warning accuracy exceeding 90%.

- Modular design becomes mainstream, increasing production efficiency by 50%.

4.2. Medium-Term (2028-2030):

- Bio-based materials account for 30%, achieving a "green closed loop".

- Full coverage of digital twin technology, with full life-cycle management becoming standard.

- Cross-industry integration forms new business models, extending the value chain by over 50%.

4.3. Long-Term Outlook (2030+):

- Geocells upgrade from "auxiliary materials" to "core components" of infrastructure.

- Deep integration with artificial intelligence and biomimetic materials, achieving adaptive adjustment.

- Global market size exceeds US$50 billion, with Chinese companies accounting for over 35% of the market share.

5. Improvements in Construction Processes

Standardized Construction and Strict Control

- Precise Laying: During laying, the cell blocks should be fully stretched and kept taut. Use anchors or edge backfilling to effectively fix them and prevent displacement during backfilling.

- Orderly Filling: Follow the principle of "symmetrical filling from the center outwards." Strictly control the unloading height (recommended not to exceed 1 meter) and select appropriate construction machinery to avoid creating excessively deep ruts that could damage the cell blocks.

- Timely Protection: After the cell blocks are laid, backfilling should be carried out as soon as possible to avoid prolonged exposure of the materials. Regularly check for any damage and address it promptly.

Strengthen Quality Awareness Throughout the Process

- From design, material selection, construction to acceptance, each stage should have clear quality control standards. For critical structures like retaining walls, it is even more crucial to prevent uncontrolled construction quality and secondary construction damage.

6. Application Area Expansion

| Areas | New Application Scenarios | Value Enhancement |

| Transportation Infrastructure | Roads in permafrost areas, ports and wharves, heavy-duty roads | Settlement reduced by 40-60%, lifespan extended by 2-3 times |

| Ecological Engineering | Mine restoration (annual growth rate 24%), wetland protection, carbon sequestration projects | Ecological restoration costs reduced by 50%, carbon sequestration capacity enhanced |

| Municipal Construction | Sponge cities, rooftop greening, underground parking garage roofs | Rainwater utilization rate increased by 40%, space utilization improved |

| Energy Engineering | Wind power/photovoltaic foundations, geothermal development sites | Construction cycle shortened by 50%, maintenance simplified |

| Military Engineering | Temporary roads, rapid fortifications, border protection | Improved mobility, enhanced concealment |

7. Related Questions and Answers

7.1 What are the main parameter optimizations?

A: During design, the interaction of multiple factors such as cell height, weld spacing, filler type, and underlying layer compaction degree should be systematically considered.

7.2 What are the standards for filling geocells?

A: Follow the principle of "symmetrical filling from the center outwards." Strictly control the unloading height (recommended not to exceed 1 meter) and select appropriate construction machinery to avoid excessively deep ruts that could damage the geocells.

7.3 What are some common problems encountered by manufacturers during geocell construction?

A: Inaccurate positioning or looseness during installation; damage to the geocells during filling; and improper filling techniques leading to geocell deformation or ruts.

7.4 What is the purpose of drilling holes?

A: To increase water permeability and the penetration of plant roots.

8. Conclusion

In summary, geocells are currently in a golden age of technological upgrading and explosive application. Their future is no longer limited to a simple geosynthetic material, but is evolving into: practitioners of green infrastructure, co-builders of ecological civilization, and components of intelligent engineering.

With the continuous advancement of materials science, manufacturing technology, and design theory, geocells will undoubtedly play an increasingly irreplaceable role in building safer, greener, and smarter human infrastructure and natural environments, and their market prospects are very bright. The above is a summary of the future functional enhancement directions and market demand exploration of geocells, compiled and released by Lianxiang Geotechnical. We hope this explanation will be helpful for your future understanding of geocells.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188