Requirements and International Standards for Geocell Wall Thickness in Different Application Fields

The wall thickness of geocells is a primary consideration for consumers when purchasing geocells, mainly because it directly affects key indicators such as tensile strength, elongation, and service life. However, focusing solely on wall thickness can sometimes lead to unnecessary waste, as thicker walls generally mean higher costs. Therefore, it's crucial to select products that meet specific project requirements. Today, we'll explain the wall thickness requirements and international standards for geocells in different application areas, hoping this information will be helpful when purchasing geocells in the future.

1. Basic Concepts of Geocell Wall Thickness

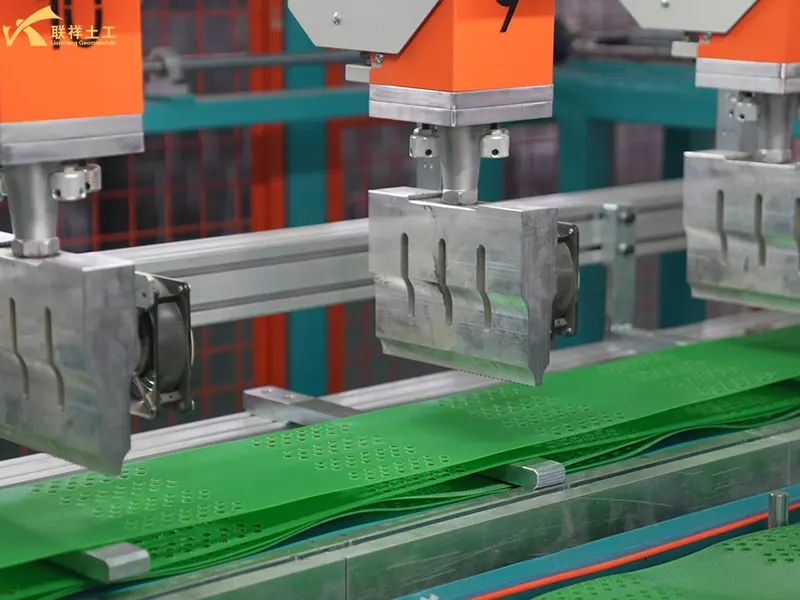

Geocells are honeycomb-shaped three-dimensional structural materials formed by ultrasonic welding of HDPE (high-density polyethylene) or PP (polypropylene) sheets. Wall thickness refers to the thickness of the strips that make up the cells and is a key parameter affecting their load-bearing capacity and durability.

General Wall Thickness Range:

- Standard Engineering: 1.0~1.5mm

- Heavy Engineering: 1.5~2.3mm

- Extra-Heavy Engineering: ≥2.0mm

2. Wall Thickness Requirements for Different Application Areas

2.1. Highway Engineering

- Subgrade Reinforcement: Sheet thickness >1.0mm, recommended 1.1~1.2mm, height 20cm, welding distance 30~40cm

- Soft Soil Treatment: Thickness ≥1.0mm, suitable for shallow soft soil < 6m

- Slope Protection: Smooth type 1.0~1.1mm, Textured type 1.4~1.5mm

2.2. Railway Engineering

- Subgrade Reinforcement: Thickness 1.5mm, suitable for heavy-haul railways

- General Railways: Thickness ≥1.1mm when height ≥150mm; Thickness ≥0.8mm when height 120~150mm

2.3. Water Conservancy Engineering

- Large dams/levees: Thickness ≥ 2.0mm, for ultra-high strength requirements

- River management: Thickness 1.5~2.0mm, resistant to water erosion

2.4. Slope protection and erosion control

- General slopes: Thickness 1.0~1.5mm, height 50~200mm

- Steep slopes/landslide management: Thickness 1.5mm, providing high lateral restraint

2.5. Other applications

- Parking lots/passages: Thickness 1.1~1.6mm, height 50~200mm

- Mining: Thickness 0.5~2.0mm, adaptable to different geological conditions

- Airport runways: Thickness ≥ 1.5mm, withstands heavy aircraft loads

- Desert/beach management: Thickness 1.0~1.5mm, resistant to environmental erosion

2.6. Principle of matching wall thickness and cell height

- Cell height ≤ 75mm: Thickness ≥ 0.8mm

- Cell height ≥ 100mm: Thickness ≥ 1.1mm

- Cell height ≥ 150mm: Thickness ≥ 1.1mm

3. International Standards and Test Methods

3.1. Major International Standards

| Standard Number | Standard Name | Scope |

| ASTM D5199 | Standard Test Method for Nominal Thickness Measurement of Geosynthetics | Thickness Measurement of All Geosynthetics |

| GRI-GS14 | Standard Method for Geocell Wall Thickness Calculation | Particularly Applicable to Textured or Embossed Geocells |

| ISO 13426-1:2019 | Strength of Internal Structural Connections in Geosynthetics - Part 1: Geocells | Test for Weld Strength of Geocells |

| DIN EN ISO 9863-1:2020 | Standard for Determination of Thickness of Geosynthetics | Method for Thickness Measurement under Specific Pressures |

| GB/T 19274-2003 | China National Standard for Plastic Geocells | Specifies Product Classification, Technical Requirements, and Test Methods |

| JT/T 516-2004 | Geosynthetics for Highway Engineering in China - Geocells | Highway Engineering Specific Standard |

3.2. Detailed Explanation of Wall Thickness Test Methods

ASTM D5199 Standard Method

- Measurement Principle: Measuring the vertical thickness of geosynthetic materials under specific pressure

- Test Conditions:

- Geotextile: Pressure 2±0.02 kPa, duration 5 seconds

- Geomembrane: Pressure 20±0.2 kPa, duration 5 seconds

- Accuracy Requirements: Measuring instrument accuracy ≥0.02 mm, median of 10 samples tested

GRI-GS14 Recommended Method (Replaces ASTM D5199 for textured geocells)

- Calculation Formula: Wall Thickness (mm) = Sample Mass (g) ÷ (Sample Area (mm²) × Material Density (g/cm³))

- Test Procedure:

- Cut 10 specimens, approximately 50mm × 50mm.

- Accurately measure the mass of each specimen (accuracy 0.001g)

- Measure the specimen area (accuracy 1mm²)

- Determine the material density (according to ASTM D1505)

- Calculate the average wall thickness

4. Wall Thickness Selection Basis and Precautions

4.1. Selection Based on Engineering Load

- Light Load: 1.0~1.2mm (Parking lots, sidewalks)

- Medium Load: 1.2~1.5mm (Ordinary highways, general slopes)

- Heavy Load: 1.5~2.0mm (Railways, airports, large retaining walls)

- Extra Heavy Load: ≥2.0mm (Large-scale water conservancy projects)

4.2. Selection Based on Material Properties

- HDPE material density should be 0.935~0.965g/cm³

- Weld strength ≥100N/cm, oxidation induction time ≥20min

4.3. Key Precautions

- Wall Thickness and Height Matching: The greater the height, the thicker the wall needs to be to prevent buckling.

- Texture Influence: The actual wall thickness of textured geocells will be slightly less than the nominal value; a +10% manufacturing tolerance should be considered.

- Test Method Selection: GRI-GS14 should be preferred over ASTM D5199 for textured geocells.

5. Issues Related to Geocell Wall Thickness

5.1. Wall Thickness vs. Cost

- Issue: Increased wall thickness means increased raw material consumption, directly leading to higher product costs.

- Trade-off: Engineers need to find the optimal balance between "minimum wall thickness to meet engineering safety" and "controlling project costs." Blindly choosing thick walls will result in waste, while choosing excessively thin walls to save costs will introduce engineering risks.

5.2. Wall Thickness vs. Flexibility and Fit

- Issue: The thicker the wall, the stronger the rigidity of the sheet, but the lower the flexibility.

- Trade-offs: When constructing on uneven foundations (such as undulating slopes), the cell structure needs good flexibility to conform to the ground and reduce gaps. Excessively thick cells may not fit well, affecting overall integrity. Thin-walled cells have advantages in this regard, but sufficient strength must be ensured.

5.3. Wall Thickness vs. Joint/Weld Strength (One of the Most Critical Issues)

- Problem: Cell failure is often not due to sheet breakage, but rather tearing or peeling at the joints (welds). Increasing wall thickness does not always linearly improve joint strength.

- Trade-offs: Joint strength depends on welding quality (e.g., ultrasonic welding), material compatibility, and weld area and design. A cell with a very thick wall but poor welding may have a much lower actual load-bearing capacity than a thinner cell with excellent welding. Joint strength is a more important performance indicator than wall thickness.

5.4. Wall Thickness vs. Long-Term Creep Performance

- Problem: Polymer materials undergo slow plastic deformation (creep) under long-term loads. Wall thickness is a crucial factor affecting creep resistance, but the molecular weight of the material (e.g., HDPE vs. HMWPE, the latter having a higher molecular weight) and additive formulation are equally important.

- Trade-off: For permanent projects (such as highway subgrades), high creep resistance materials must be selected. Sometimes, using medium-walled materials with higher molecular weights may result in better long-term performance than thick-walled materials with lower molecular weights.

5.5. Nominal Wall Thickness vs. Actual Minimum Wall Thickness

- Problem: Uneven thickness may occur during production. International standards (such as ASTM) typically require measurement of both average and minimum wall thickness.

- Trade-off: When purchasing, it is necessary to clarify whether the technical specifications require the minimum or average value. A product promising an "average 1.2mm" but with large tolerances may have a thinnest point of only 0.9mm, becoming a weak point.

6. Other Key Factors Closely Related to Wall Thickness

6.1. Material Type

- Polypropylene (PP): Low density, lower cost, but relatively poor low-temperature brittleness and UV resistance. A thicker wall thickness may be required to compensate for this.

- High-density polyethylene (HDPE): Good toughness and chemical resistance; a commonly used material.

- High molecular weight polyethylene (HMWPE): Optimal strength and creep resistance; suitable for heavy-duty projects. For the same strength requirements, a relatively thinner wall thickness may be permissible.

6.2. Filler Type and Construction Machinery

- Sharp fillers (e.g., crushed stone): Risk of abrasion and puncture to the wall material; requires thicker walls or materials with higher puncture resistance.

- Heavy construction machinery: During filling and compaction, direct crushing or impact from machinery requires sufficient impact and localized buckling resistance in the cell; wall thickness is critical.

6.3. Environmental Exposure Conditions

- Ultraviolet (UV) radiation: Cells exposed to sunlight require the addition of UV stabilizers. Wall thickness provides a "mass reserve" for the material, allowing for the sacrifice of some surface material to maintain overall performance. Thin-walled cells have higher requirements for UV stability.

- Chemical environment: In acidic or alkaline environments such as landfills and tailings ponds, the chemical stability of the material is more important than wall thickness.

7. Conclusion

- 7.1. Wall thickness is a core parameter, but not the only one: it must be comprehensively selected in conjunction with joint strength, long-term creep performance of the material, UV resistance rating, filler type, and design load.

- 7.2. Follow the principle of "performance-based design": First, perform engineering calculations to determine the required reinforcement strength, modulus, and slip resistance, etc., and then select the appropriate model based on the product data sheets provided by the manufacturer that conform to ASTM or GRI testing standards.

- 7.3. Consult professional manufacturers: Mainstream geocell manufacturers (such as Lianxiang Geotechnical) have mature product series and application guidelines, and can provide wall thickness and model recommendations for specific projects.

- 7.4. Refer to successful case studies: In projects with similar geological conditions and engineering requirements, product specifications with successful application cases are the most reliable reference.

The selection of geocell wall thickness needs to comprehensively consider the application scenario, load conditions, cell height, and material properties. The general rule is: the greater the load and the higher the height, the greater the required wall thickness. Internationally, standards such as ASTM D5199, GRI-GS14, and ISO 13426-1 are mainly used for wall thickness testing and quality control, while China implements national standards such as GB/T 19274-2003 and JT/T 516-2004. In summary, selecting geocell wall thickness is a systematic project that requires balancing functional requirements, safety factors, cost, and standard compliance. International standards (especially the ASTM and GRI series) provide a scientific and unified benchmark for evaluating and comparing different products.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Kyle Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188