Aging mechanism of geogrid and methods to slow down its aging rate

Geogrid aging refers to the process by which, over long-term use, the physical and chemical properties of geogrids gradually deteriorate due to environmental factors, ultimately leading to material failure. The aging mechanism of geogrids is a complex, multi-factor coupled process that can be categorized as chemical aging and physical aging. It is also influenced by construction damage and biodegradation. The primary aging factors are UV radiation, high temperatures, oxidation, and chemical attack. Slowing down aging relies on the four key principles of "avoidance, selection, protection, and management."

I. Geogrid Aging Mechanisms

1. Chemical Aging

This is the most common form of aging in polymer materials, primarily caused by molecular chain breakage and crosslinking.

1.1. Thermo-oxidative Aging

- Mechanism: Under the combined effects of oxygen and heat, polymer chains undergo auto-oxidation. This is a free radical chain reaction:

- Initiation: Under the influence of heat or light, weak links (such as tertiary carbon atoms) in the polymer chain (RH) break, generating free radicals (R·).

- Growth: Free radicals react rapidly with oxygen to form peroxyl radicals (ROO·). These free radicals then extract hydrogen from other polymer chains, forming hydroperoxides (ROOH) and new free radicals (R·), continuing the reaction cycle.

- Termination: Free radicals combine to form stable products, terminating the reaction.

- Consequences: Molecular chain breakage leads to a decrease in material molecular weight, a sharp drop in tensile strength and modulus; crosslinking of molecular chains causes brittleness and a decrease in elongation. High temperatures greatly accelerate this process.

1.2. Photooxidative Aging (UV Aging)

- Mechanism: Ultraviolet (UV) radiation in sunlight has high energy, sufficient to directly break chemical bonds (such as C-C and C-H bonds) in polymers, generating free radicals and initiating oxidation reactions similar to those of thermal oxidative aging.

- Consequences: This primarily occurs on the material surface, causing surface chalking, discoloration, cracking, loss of gloss, and a significant decrease in mechanical properties. This is the primary aging factor for geogrids exposed to sunlight for long periods of time, such as in slope reinforcement.

1.3. Hydrolysis Aging

- Mechanism: Water molecules penetrate the polymer and react chemically with certain hydrolyzable groups (such as ester groups -COO-) on the polymer chain, causing the chains to break.

- Consequences:

- Polyester grids are most vulnerable to hydrolysis because their backbone contains numerous ester groups. The hydrolysis rate increases exponentially at high temperatures (e.g., >40°C) and in alkaline environments (pH >9).

- Polypropylene grids: Their molecular chains consist of carbon-carbon bonds and lack hydrolyzable groups, resulting in excellent hydrolysis resistance.

- High-density polyethylene grids: They also have good hydrolysis resistance.

1.4. Chemical Corrosion

- Mechanism: Chemical substances such as acids, alkalis, salts, and organic solvents that may be present in the fill environment can react with the polymer or act as catalysts to accelerate its hydrolysis and oxidation processes.

- Consequences: For example, alkaline environments (such as cement-stabilized soil and lime-treated soil) can strongly catalyze the hydrolysis of polyester grids. Chemical substances from certain industrially contaminated sites can also directly corrode the grids.

2. Physical Aging

2.1. Creep and Stress Relaxation

- Mechanism: Under long-term, sustained loads, polymer molecular chains slip and rearrange, resulting in irreversible deformation (creep) or a gradual decay of stress over time (stress relaxation).

- Consequences: While not entirely "aging," it is one of the primary failure modes of polymer geosynthetics under long-term stress. Excessive creep deformation can lead to structural instability. The long-term creep strength of the material must be considered during design.

2.2. Physical Damage

- Construction Damage: During the laying and backfilling process, debris and sharp objects can puncture and scratch the grid, causing initial defects. These damaged points become stress concentration points, accelerating crack propagation.

- Abrasion: Long-term relative motion with soil particles can cause wear on the grid surface, thinning the transverse ribs and reducing the effective cross-section.

3. Biological Aging

- Mechanism: Certain microorganisms (such as bacteria and fungi) as well as insects and rodents may feed on polymer additives (such as plasticizers and oils) or directly erode the polymer itself.

- Consequences: This process is generally slow, but in certain environments (such as landfills and soils with high organic matter content), it can become a significant factor.

4. Comparison of Aging Characteristics of Geogrids of Different Materials

| Material | Main Chemical Aging Threats | Advantages | Disadvantages |

| Polypropylene | Thermal oxidative aging, UV aging | Good hydrolysis and chemical resistance (especially to acids and alkalis); low cost | Poor UV resistance, requiring the addition of UV inhibitors; brittle at low temperatures |

| Polyester | Hydrolytic aging (especially in high-temperature alkaline environments), thermal oxidative aging | High modulus, excellent creep properties, and good fatigue resistance | Extremely sensitive to pH and temperature, not suitable for alkaline environments |

| High-density polyethylene | Thermal oxidative aging, UV aging | Excellent chemical resistance, low-temperature resistance, and impact resistance | Relatively high cost; long-term creep performance is inferior to polyester |

II. Methods for Delaying Geogrid Aging

1. Material Selection is Fundamental: Select Highly Weather-Resistant Materials

Selecting geogrids with stronger aging resistance from the source is the most effective method.

1.1. Material Selection:

- Polyester warp-knitted grating: Generally offers better resistance to UV aging than polypropylene grating.

- High-density polyethylene grating: Offers better resistance to environmental stress cracking and heat than low-density polyethylene.

- Fiberglass grating: An inorganic material, completely resistant to UV radiation and biodegradation, with excellent high-temperature and chemical resistance. This is the most thorough solution for combating UV aging.

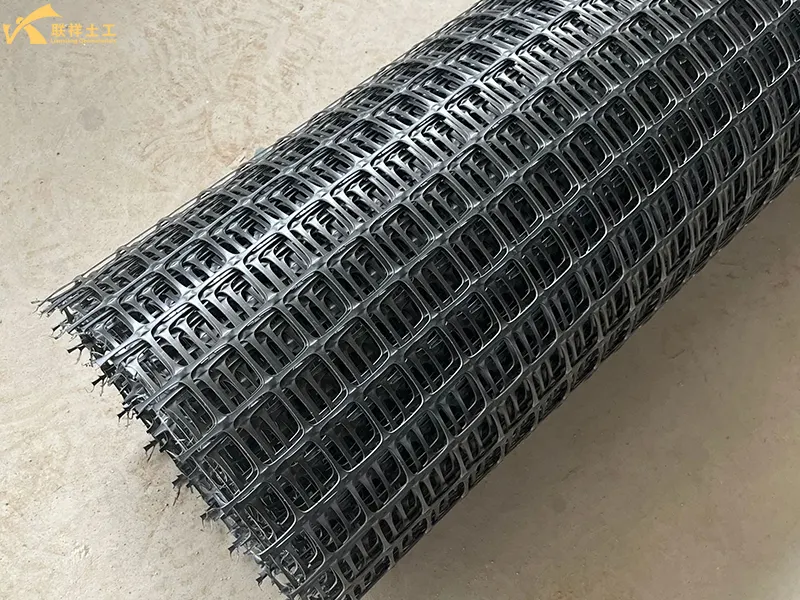

- Steel-plastic composite grating: With a steel wire core and a plastic outer layer, the steel wire provides long-term strength, while the plastic layer primarily serves as corrosion protection, resulting in excellent aging resistance.

1.2. Additives and Processing:

- Adding Anti-aging Agents: A sufficient amount of antioxidants and light stabilizers (such as UV absorbers and hindered amine light stabilizers (HALS)) are added during the production process. These additives effectively absorb or quench UV energy, preventing polymer chain breakage.

- Carbon Black Protection: For polyolefin gratings (such as HDPE and PP), adding 2%-3% highly dispersed carbon black is the most cost-effective UV protection method. Carbon black absorbs and scatters most UV rays like a parasol.

- Co-extrusion: Using co-extrusion technology, a protective layer rich in anti-aging agents is formed on the grating surface, ensuring performance while reducing costs.

2. Protection During Construction: A Key Control Link

The construction phase is when grating is most exposed to aging conditions and requires strict management.

2.1. Avoiding UV Exposure:

- Packing Immediately After Laying: Lay grating with filler should be covered as soon as possible to minimize direct exposure to sunlight. Regulations generally require exposure time to no more than 48 hours, and ideally, covering should be completed within 24 hours.

- Rational Construction Scheduling: Arrange the laying schedule based on the project volume and avoid laying the grating on site too many days in advance.

2.2. Standardized Laying Operations:

- Appropriate Tensioning: Maintain tension during laying. Avoid excessive force, which can cause initial stress within the reinforcement and accelerate stress cracking.

- Minimize Damage: Construction machinery should avoid running directly over exposed grating. If necessary, use a soft material such as sand as a cushioning layer. The connections and overlaps of the grille should be secure to prevent damage from pulling during use.

3. Structural Design Optimization: Creating a Good Service Environment

Good structural design provides a "protective shield" for the grille.

3.1. Ensure Sufficient Cover Thickness:

- The filler cover is the most direct barrier to protect the grille from UV rays and high temperatures. Ensure that the backfill thickness, as specified in the design drawings and during construction, meets the specifications (usually no less than 30 cm).

- Installing a layer of gravel or geotextile between the surface layer (such as grass mats, concrete blocks, etc.) and the grille can buffer loads, reduce localized stresses, and provide a certain degree of insulation.

3.2. Selecting Appropriate Filler:

- Use chemically stable fillers. Avoid using highly acidic or alkaline soils or soils containing large amounts of organic matter.

- Control the maximum particle size of the filler to prevent sharp-edged rocks from puncturing or scratching the grille surface during compaction.

4. Storage and Transportation Management: Prevention at the Source

Aging begins after the grating leaves the factory, so proper storage and transportation are crucial.

- 4.1. Indoor or Shaded Storage: Finished gratings should be stored in an indoor warehouse or tightly covered with waterproof tarpaulins or sheeting to protect them from direct sunlight and rain.

- 4.2. Keep away from heat sources: Storage should be away from high-temperature heat sources such as boilers and welding areas.

- 4.3. Proper Handling: Avoid mechanical damage during loading, unloading, and transportation.

III. Geogrid Material Durability Improvement Plans

Based on the aging mechanisms of different geogrid types, improvement plans must be developed from multiple perspectives, including material modification, structural optimization, construction control, and post-maintenance.

1. Material Modification Technologies

1.1. UV Resistance

- Plastic Geogrids: Adding UV stabilizers (such as hindered amine HALS and benzotriazole UV absorbers) to the raw materials, at a controlled dosage of 0.5%-2%, can increase outdoor aging strength retention to over 80%. Blending modification technology can be used to improve molecular structural stability by blending PP with polyvinyl alcohol (PVA), a material with excellent UV resistance.

- Polyester Geogrids: Surface grafting modification introduces UV-resistant functional groups (such as benzene rings) into the molecular chain, enhancing UV absorption and scattering capabilities and extending the material's aging life.

1.2. Chemical Corrosion Resistance Modification

- Plastic Grating: Chlorination or fluoride coating technology is used to form a dense protective layer on the material surface, blocking the penetration of acids, alkalis, and salts. Nano-silica (SiO₂) particles are added to PP grating to enhance the material's chemical corrosion resistance through their filling effect.

- Fiberglass Grating: The resin coating formula is optimized, using alkali-resistant epoxy resin or vinyl ester resin with a coating thickness of 0.1-0.3mm. Alkali-resistant agents (such as aluminum hydroxide) are added to the resin to slow down alkaline corrosion. Surface treatment of the glass fiber (such as silane coupling agent coating) strengthens the fiber-resin bond and improves overall corrosion resistance.

1.3. Fatigue Resistance Enhancement Modification

- Plastic Grating: A biaxial stretching process is used to optimize molecular orientation, enhancing the material's tensile strength and fatigue resistance. Arc transitions are used at the grating nodes to reduce stress concentration. Elastomers (such as EPDM) are added to improve the material's toughness and reduce the likelihood of microcracks.

- Polyester Grid: Through copolymerization modification, flexible segments (such as polyether chains) are introduced into the polyester molecular chain, improving the material's elasticity and fatigue resistance, extending its life under cyclic loading by over 50%.

2. Structural Design Optimization

2.1. Grid Structure Design:

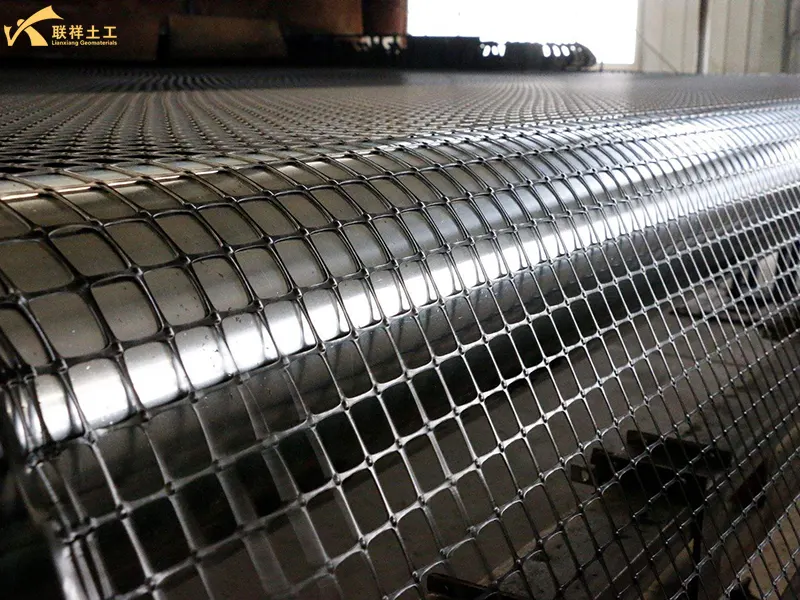

- Optimize the grid size and shape based on project requirements. For example, in roadbed reinforcement projects, a diamond grid structure (grid size 20mm×20mm-50mm×50mm) is used. Compared to a rectangular grid, this structure evenly distributes stress and reduces localized stress concentration. Increasing the width and thickness of the grid ribs improves the material's load-bearing capacity and aging resistance. Rib widths are generally no less than 3mm and thicknesses no less than 1mm.

2.2. Multi-layer Composite Structure Design:

- Utilize a "core layer + protective layer" composite structure. The core layer is constructed of high-strength materials (such as glass fiber or polyester fiber) to provide the primary load-bearing capacity. The protective layer is constructed of ageing- and chemical-resistant materials (such as modified PP or polyvinyl alcohol film). The thickness is controlled between 0.2 and 0.5mm, effectively shielding the core layer from the effects of external aging factors. For example, composite glass fiber geogrids, through their composite structural design, can improve their alkali-aging resistance by 40%-60%.

3. Construction and Maintenance Control

3.1. Construction Process Control

- Laying Environment Control: Avoid construction in high temperatures ( > 40°C), extremely cold weather ( < -10°C), or rainy weather to prevent premature aging of the material due to environmental factors during construction. For plastic grating, avoid dragging during installation to prevent surface scratches and damage to the protective layer.

- Optimized Connection Methods: Use hot-melt welding or high-strength bolts instead of traditional lashing to ensure joint strength and sealing, and reduce the infiltration of moisture and chemicals. The hot-melt welding temperature should be adjusted according to the material type. The welding temperature for PP grating is generally 180-220°C, and for PE grating, it is 160-200°C.

3.2. Post-Maintenance Strategies

- Regular Inspection: Use non-destructive testing techniques (such as ultrasonic testing and infrared thermal imaging) to inspect the mechanical properties and appearance of geogrids every one to two years to promptly detect aging damage. For geogrids used in road projects, this can be combined with pavement inspections and core sampling to analyze the extent of geogrid aging.

- Repair and Replacement: For locally aged or damaged geogrids, patch repairs should be performed using the same type and specification of geogrid material, using hot-melt welding. When the overall strength retention rate of the geogrid falls below 70%, it should be promptly replaced to avoid potential safety hazards.

- Environmental Protection: Cover the geogrid installation area with a protective layer (such as geotextile or asphalt surface layer) to reduce the direct effects of ultraviolet rays and rainwater on the geogrid. For geogrids used in underground projects, add corrosion inhibitors to the surrounding soil (such as adding gypsum to adjust the soil pH in saline-alkali soil) to improve the service environment.

Conclusion

Geogrid aging is a complex process driven by multiple factors, including heat, oxygen, light, water, chemical media, and stress. The core issue is the chemical degradation (oxidation and hydrolysis) of polymer molecular chains, accompanied by a decline in physical properties. Understanding the sensitivity of different geogrid materials to various aging factors is crucial for selecting the right material and ensuring the long-term safety and stability of the project. Accelerated aging tests are often used in projects to predict the long-term performance of materials and provide a basis for design.

To effectively slow the aging of geogrids, a systematic, comprehensive approach is required:

- Core (Selection): Prioritize HDPE geogrids with added carbon black, polyester geogrids, or fiberglass geogrids that fundamentally address the problem.

- Key (Protection): Strictly adhere to the "lay and fill" principle during construction; this is the lowest-cost and most effective on-site protection measure.

- Guarantee (Management): Ensure proper storage and transportation management from the factory to pre-installation to prevent unnecessary premature aging.

- Foundation (Design): Provide a robust, stable, and harmless long-term service environment through rational structural design.

Through the comprehensive application of the above methods, the aging process of geogrids can be delayed to the greatest extent, ensuring that they can continue to play a role in reinforcement and strengthening within the designed service life, thereby ensuring the safety and durability of the project.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Editor Fan

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188