Analysis of the construction steps of geocell slope protection project

Currently, geocell are the most widely used product in the geotechnical material industry for slope protection projects. However, their construction is significantly more difficult than other materials. Today, we will focus on the construction steps for geocell slope protection.

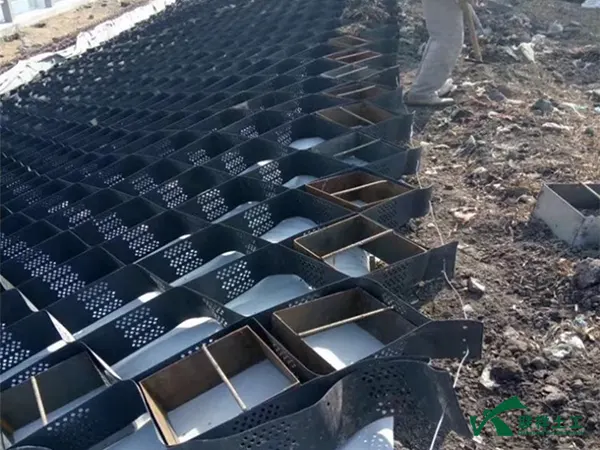

Geocell slope protection differs from geogrid slope protection (primarily used for reinforced earth retaining walls) in its principles and applications. Geocells are three-dimensional honeycomb structures that, by limiting the lateral displacement of the filler within, form a structural layer with significant lateral restraint and rigidity. They are widely used in applications such as shallow slope protection and ecological restoration.

The following are detailed construction steps and key points.

I. Construction Preparation Phase

1. Technical Preparation:

- Drawing Familiarization: Thoroughly review the design drawings to clarify the cell model (weld spacing, height), installation range, anchoring method, fill material, and vegetation requirements.

- Scheme Briefing: Provide detailed technical and safety briefings to the construction team.

- Schedule Planning: Develop a construction plan, paying particular attention to slope drainage and vegetation requirements during the construction season.

2. Site Preparation:

- Construction of Access Roads: Ensure that construction machinery and material transport vehicles can reach the top and toe of the slope.

- Establishment of Safety Measures: Set up cordon lines at the top and toe of the slope, and install safety ropes for construction workers (for steep slopes).

- Surveying and Staking: Use a total station or GPS to determine the slope treatment area, the location of the toe foundation, and the locations of various platforms.

3. Material and Equipment Preparation:

- Main Materials: Geocells (check specifications, quantity, and damage), anchors (L- or U-shaped rebar nails, wooden wedges, bamboo sticks, etc.), and filler (planting soil, sandy loam, gravel, etc., which must be sieved).

- Supplementary Materials: Geocell connectors, PVC drain pipe (if required).

- Equipment: Transport vehicle, air compressor, pneumatic drill (for anchoring rock slopes), tamping machine, watering equipment, and spray seeding machine (if soil seeding is required).

II. Slope Treatment

This is key to ensuring the cells are tightly integrated with the slope.

1. Slope Clearing and Shaping:

- Remove all loose soil, loose rocks, tree roots, and debris from the slope.

- Roughly level the slope, fill any potholes, and smooth out any protrusions to create a smooth surface. The final slope should be slightly lower than the designed slope line by approximately one cell height to ensure the cells do not bulge after installation.

2. Slope Stabilization:

- For unstable slopes, slope reduction, retaining walls, and anti-slip piles should be implemented first to ensure the main structure is stable before cell construction.

3. Foundation Installation:

- Excavate a shallow foundation trench at the toe of the slope to bury the starting end of the cells and prevent them from sliding down.

III. Drainage Facility Construction

Water is the primary factor contributing to slope instability and must be addressed first.

- Excavate and build a drainage ditch at the top of the slope to prevent rainwater from pooling and eroding the slope.

- According to the design requirements, PVC drainage pipes are installed at regular intervals on the slope to drain water behind the cell layer. Geotextile fabric should be wrapped around the drainage pipe inlet as a filter layer to prevent clogging.

IV. Geocell Laying and Anchoring

This is the most critical and technical step.

1. Layout and Positioning:

- On the prepared slope, lay out the cell laying areas and anchor holes.

2. Laying Direction:

- The cells should be laid perpendicular to the route (i.e., from top to bottom). Lay from the top of the slope to the bottom.

3. Tensioning and Deployment:

- Deploy the bundled cells at the top of the slope and temporarily secure them to the top with main anchors (longer, thicker anchors).

- Draw the cells downward along the slope, ensuring they are fully tensioned, either manually or mechanically, to form a regular honeycomb shape. Insufficient tensioning will cause the cells to sag, affecting subsequent filling and the overall quality.

4. Anchoring:

- Top Anchoring: Use main anchors at the top of the slope for permanent fixation, with closely spaced anchors.

- Slope Surface Anchoring: Use L-shaped or U-shaped rebar nails, wooden wedges, or other similar anchors to drive into the slope surface from the center of each cell or every other cell in the expanded structure, securing the cell firmly to the slope. For rock slopes, first drill holes with a pneumatic drill, then insert anchors and secure with mortar.

- Perimeter Anchoring: Use anchors to secure the cell perimeter (especially at the junction with the intercepting drain).

5. Cell Connection:

- If the cell width is insufficient, use specialized cell connectors (usually J-shaped or C-shaped clips) to securely connect adjacent cell sections. Simple wire ties are strictly prohibited to prevent weak links.

V. Cell Infilling

1. Infilling Method:

Infilling should be carried out from the top of the slope to the bottom, and from the center of the cell to the perimeter. There are three main methods:

- Manual filling: This is the most commonly used method, suitable for a variety of fillers and ensuring high density and uniformity.

- Mechanical filling: For gentle slopes, a small loader can be used to pour soil from the top of the slope, then manually leveled.

- Spray filling: For ecological slope protection, soil mixed with seeds can be sprayed directly into the cells using a sprayer. This method is highly efficient and provides good binding.

2. Filling Requirements:

- The fill material should be slightly higher than the cell height (1-2 cm higher), allowing space for natural settlement.

- The fill must be full and gently compacted with a mallet or other tool. Vehicles and heavy machinery are strictly prohibited from driving directly over filled but unstabilized cells.

- For engineering slope protection requiring high strength (such as river channels and coastlines), crushed stone, gravel, etc. can be used; for ecological slope protection, improved planting soil can be used.

VI. Vegetation Restoration (Ecological Slope Protection)

This is a key step in realizing the ecological benefits of geocells.

1. Vegetation Selection:

- Choose grass and shrub seeds or seedlings that are suitable for the local climate, have well-developed root systems, and are drought- and barren-resistant.

2. Construction Method:

- Spraying: Mix seeds, fertilizer, adhesives, water-retaining agents, wood fiber, and other ingredients with water and evenly spray them onto the surface of the filled cells using a hydraulic sprayer.

- Planting: Plant shrubs or seedlings directly within the cell grid or lay turf.

3. Maintenance:

- Water and maintain the slope regularly until the vegetation covers the slope, forming a stable ecological barrier.

Key Considerations and Quality Control Points

- 1. Slope Preparation is the Foundation: Uneven slopes can cause cells to hang loose, resulting in uneven stress after filling and easy damage.

- 2. Adequate Tensioning is Key: Untensioned cells are ineffective and cannot provide effective lateral confinement.

- 3. Secure Anchoring is the Guarantee: The number and pullout resistance of anchor rods must meet design requirements to prevent the cells from sliding.

- 4. Density of fill is key: Loose fill cannot form a monolithic structural slab effect, significantly compromising strength.

- 5. Drainage is crucial: Accumulated water within the slope must be drained smoothly to prevent hydrostatic pressure from damaging the structure.

- 6. Material protection: Geocells (especially HDPE materials) should be protected from prolonged sunlight exposure. They should be laid, anchored, and filled immediately to minimize the effects of UV aging.

Through the detailed steps above and rigorous quality control, geocell slope protection projects can achieve the desired protection, stability, and ecological benefits.

The above are the construction steps for geocell slope protection projects. Generally speaking, the entire process must adhere to the basic principles of "slope clearing, footing, deployment, anchoring, filling, and vegetation." Slope protection projects require high quality, carry significant impact, and carry a heavy responsibility. We must strictly follow standard procedures during construction. Please feel free to contact us for any related inquiries.

Written by

SHANDONG LIANXIANG ENGINEERING MATERIALS CO., LTD.

Editor Fan

www.lianxiangcn.com

WhatsApp:+86 139 5480 7766

Email:admin@lianxiangcn.com

Contact

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188