Excellence Through Innovation

Application Overview

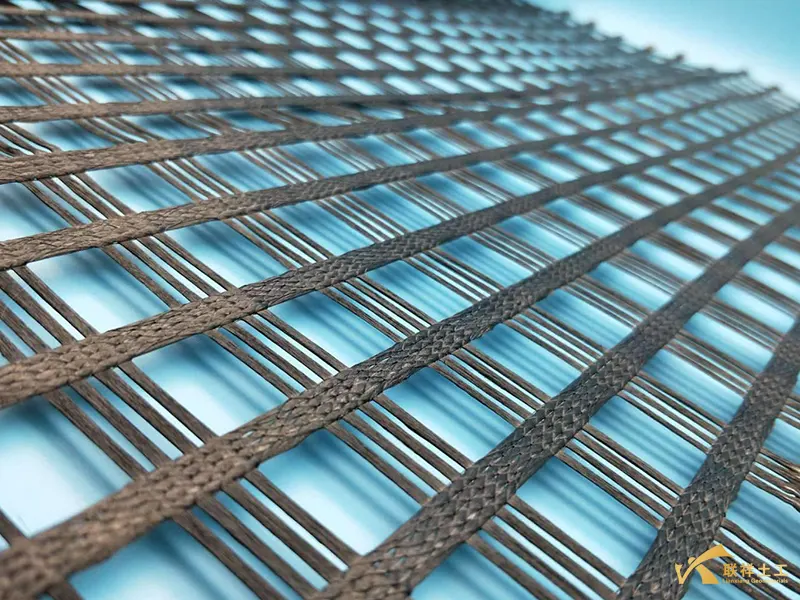

Geogrid is an important geosynthetic material in road construction. It mainly improves the mechanical properties of soil through its high strength and unique grid structure. It is widely used in scenarios such as roadbed reinforcement, pavement crack resistance, and slope stabilization.

Roadbed geogrids are made of high-strength polymers with a unique grid pattern. This grid structure gives them excellent mechanical properties, effectively enhancing roadbed stability. When laid in the roadbed, geogrids act like a strong net, tightly connecting the particles within the roadbed and preventing them from shifting and deforming under external forces such as vehicle loads.

Roadbed geogrids are made of high-strength polymers with a unique grid pattern. This grid structure gives them excellent mechanical properties, effectively enhancing roadbed stability. When laid in the roadbed, geogrids act like a strong net, tightly connecting the particles within the roadbed and preventing them from shifting and deforming under external forces such as vehicle loads.

- Description

Addressing Three Core Issues

Geogrids are mesh structures made of high-strength materials such as polyester or polypropylene, offering high tensile strength and stiffness. In roadbed filling projects, geogrids can serve the following purposes:

1. Anti-settlement

- Soft soil foundations: Geogrids can be used to distribute loads and reduce uneven subgrade settlement (e.g., bidirectional plastic geogrids).

- New and old subgrade splicing: Coordinate differential settlement during widening projects to prevent longitudinal cracking.

2. Anti-crack

- Reflective crack blocking: Fiberglass geogrids can be installed between the old pavement and the new asphalt layer to absorb stress and slow crack propagation (reducing reflective cracking by over 80%).

- Base crack prevention: Geogrids can be placed between the cement-stabilized crushed stone base and the asphalt surface layer to prevent shrinkage cracking.

3. Anti-landslide

- Steep slope reinforcement: High-strength steel-plastic geogrids (tensile strength ≥80kN/m) can be embedded to form reinforced earth retaining walls, improving the slope's resistance to sliding. - Ecological Slope Protection: Combined with grass mats, this system achieves integrated soil consolidation and greening.

Key Application Scenarios

| Scenario | Applicable Grid Type | Effect |

| Roadbed Reinforcement | Plastic Grid (HDPE/PP) | Improves bearing capacity and reduces filler thickness by 20%-30% |

| Pavement Crack Prevention | Fiberglass Grid/Warp-Knitted Polyester Grid | Delays reflective cracking and extends service life by 3-5 years |

| High and Steep Slopes | Steel-Plastic Composite Grid | Increases skid resistance by over 50% |

| Frozen Soil Areas | Low-Temperature-Resistant Modified Grid | Inhibits freeze-thaw deformation and reduces renovation frequency |

| Bridge Bump Treatment | High-Strength Bidirectional Grid | Alleviates differential settlement between abutments and roadbed |

Key Construction Techniques

1. Pre-Paving Treatment

- Level and compact the roadbed and remove sharp rocks (to prevent puncture of the grid).

- Soft foundations require pre-compression and drainage to prevent deformation after paving.

2. Precision Paving

- Maintain tension (wrinkle rate ≤ 5%), with U-shaped nail anchors spaced 1-1.5m apart.

- Overlap width: ≥ 30cm vertically, ≥ 50cm horizontally. Heavy-duty roads require stitching or welding.

3. Soil Control

- Filler should be rolled in layers (each layer ≤ 30cm). Direct mechanical rolling of the grid is prohibited.

- During asphalt pavement construction, the paving temperature must be < 170°C (to prevent deformation of the fiberglass grid).

Why Does It Save Money and Time?

- Material Savings: Due to the high tensile strength and stiffness of geogrids, the thickness of roadbed fill can be effectively reduced by 20% during construction, and the amount of sand and gravel used can be reduced to achieve the purpose of reducing costs.

- Time Savings: The construction of geogrid is very simple, and the product is generally 6-100 meters long, with a mechanized laying efficiency of 5,000 square meters per day, thereby shortening the soft foundation treatment cycle and improving construction efficiency.

- Maintenance Savings: Geogrids have a long service life, are corrosion-resistant, and have high compressive strength. During the entire road application period, they can reduce the frequency of rutting and crack repairs, and reduce the full life cycle cost by 15% to 30%.

Special Innovative Applications

- Emergency Repair: Rapidly lay geogrids and gravel on collapsed road sections, restoring traffic within 24 hours.

- Sponge Roads: Combined with permeable cells, these geogrids enhance roadbed permeability and reduce water accumulation.

- Recycled Plastic Geogrids: Environmentally friendly materials (such as recycled HDPE) reduce costs by 40%.

Summary:Geogrids, through their integrated functions of reinforcement, isolation, and drainage, serve as the "invisible skeleton" of road projects. Choosing the right type (plastic for soft foundations, fiberglass for crack resistance, and steel-plastic for heavy loads) and standardized construction (leveling, tensioning, and anchoring) are key to maximizing their effectiveness. In complex geological conditions and with the trend toward green construction, their application value is becoming increasingly prominent.

Contact

Address

No. 6 Great Wall Road, Taian City, Shandong, China

EMail

admin@lianxiangcn.com

Hotline

+86-185 5418 0188

Shandong Lianxiang Engineering Materials Co., Ltd. All Right Reserved

-

WhatsApp

-

E-MailE-Mail:admin@lianxiangcn.com

-

WeChatWeChat:18554180188