English

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 8 Author: Leo Publish Time: 2023-06-16 Origin: Origin self edited by Leo

1. Unrolling fabric

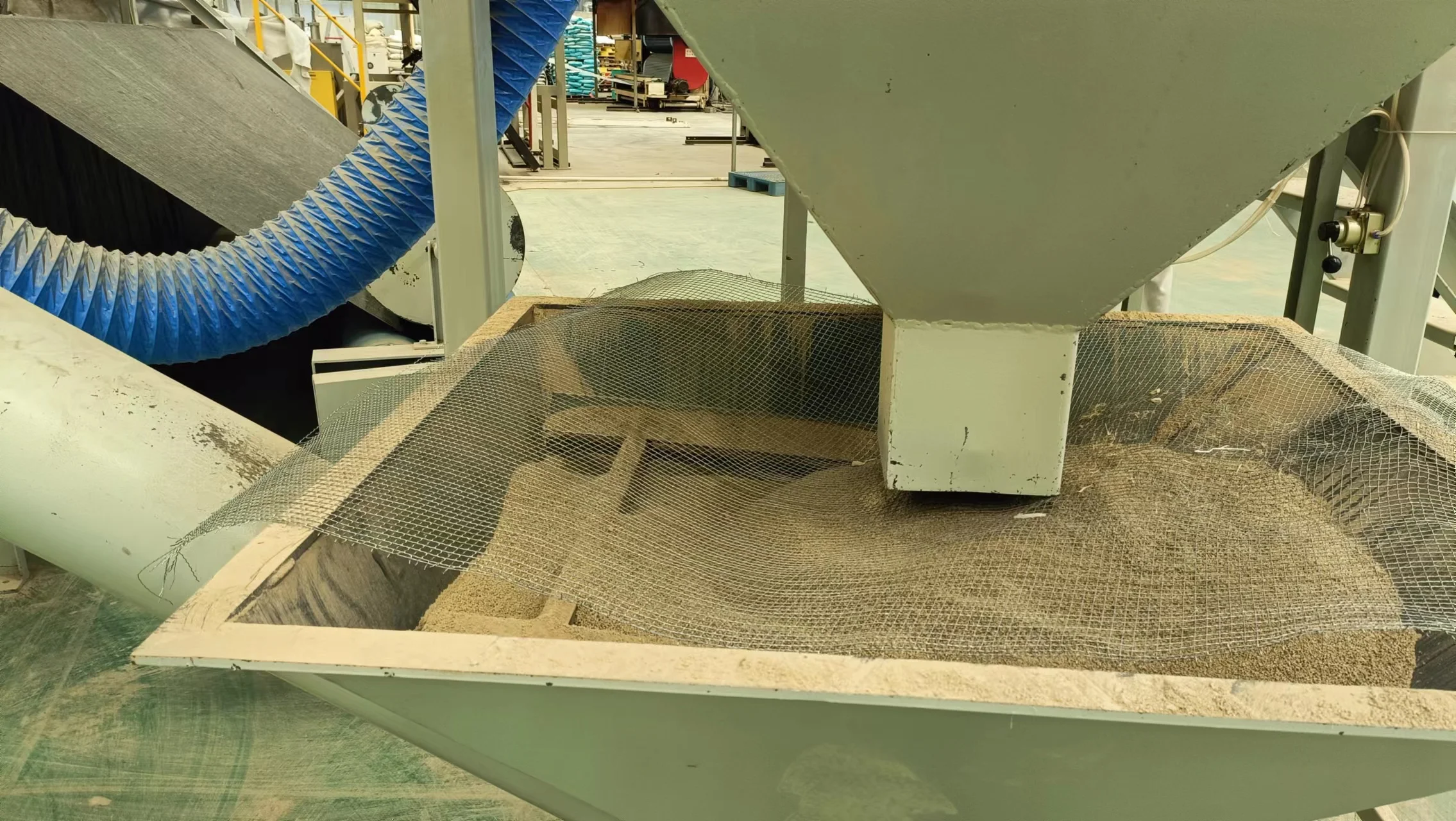

Whether can ensure the textile on top and bottom layer smoothly spreaded is the very important first step: unrolling woven fabric. Because if there happened any overlap or folded fabric during unrolling, the bentonite powder will not spilled evenly on the textile, and will cause potential leakage during installation. Lianxiang knows the importance of this first step and made a lot of improvement to guarantee the quality.

2. Coordinate

The unrolling speed of top and bottom layers of textiles must kept in pace, otherwise will causing the textile stretched too much and result in the tensile strength of the GCL lower than standard, and the GCL easily broken during installation.

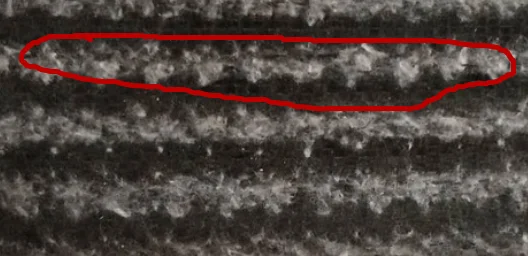

3. Punching dealing method

After long-term research by our technique team, we found irregular needle punch technique can greatly improve the peel strength of GCL than regularly punched. Besides, the waving shape needle-hole surface also helps to improve the peel strength.

The needles are barbed needles, when the needles punching through the GCL from top to bottom, it will bring down some textile fibers together. Then thermal method was used to stick these fibers on bottom woven fabric, and which will improve the peel strength of GCL.

4. Bentonite

The water sorbing capacity of GCL depend on the bentonite, and the key part of bentonite is the contains ratio of montmorillonite. China is rich in natural bentonite and we choose the best of them(from Weifang city), the montmorillonite ratio of our GCL completely meet China GB standard and far more than other standards.